JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 12

JIMMY SERIES HYDRAULIC REBAR BENDERS — GENERAL INFORMATION

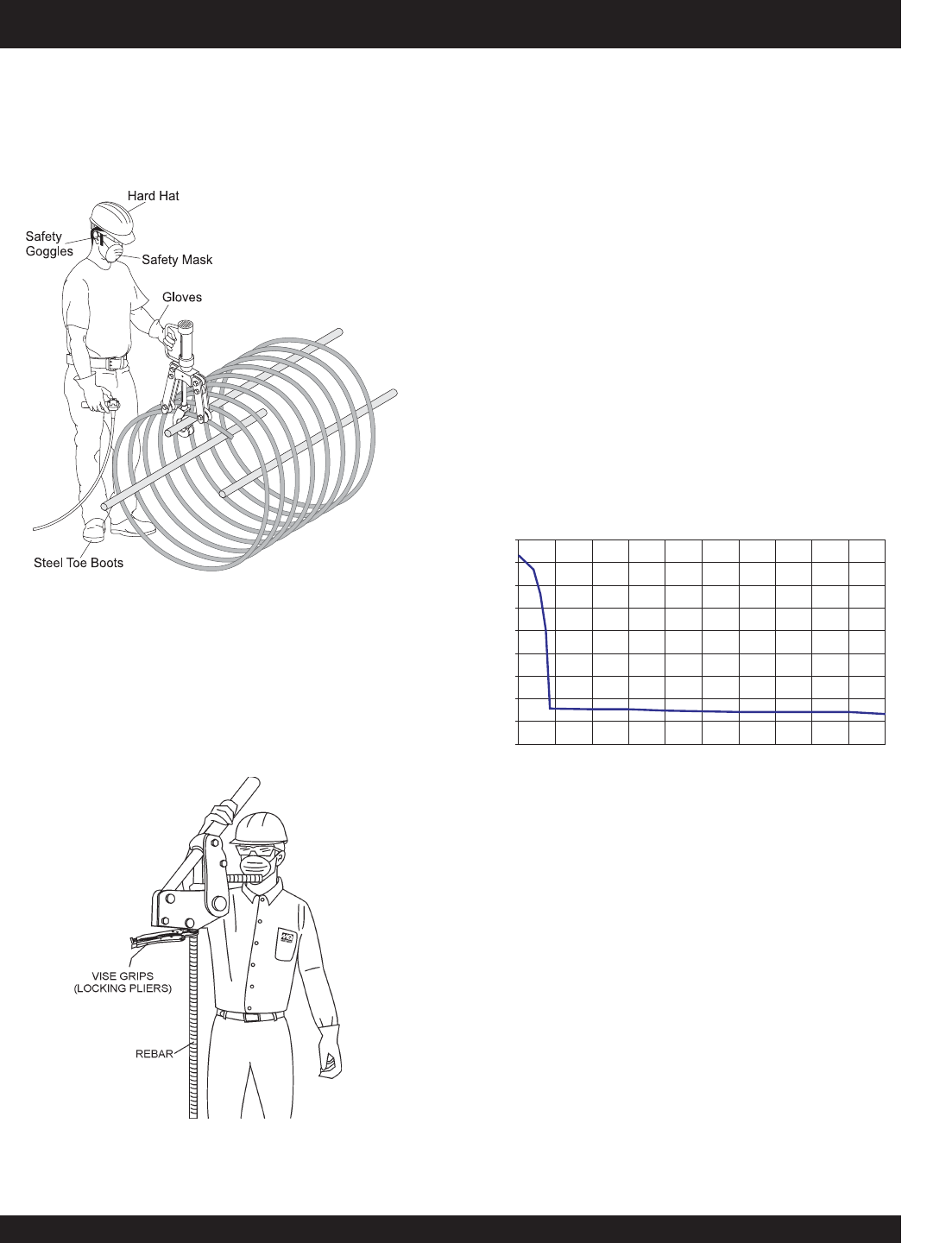

Rebar Spirals and Cages

■

Can bend rebar up to 135° (Figure 3) and fits between spirals

as close as 2 in. (5 cm. ) on center.

■

No welding required.

Figure 3. Rebar Spirals and Cages

Rebar Walls

■

No welding required

■

Bends hooks in rebar after forms have been removed.

■

Bends graduated bars to precise elevations.

■

Reduces size and number of holes and splices required in

forms.

Figure 4. Rebar Walls

Electric-Hydraulic Pump

All Jimmy Series Hydraulic Rebar Benders require an electric-

powered hydraulic pump to supply the necessary pressure to actuate

the hydraulic cylinder. This hydraulic pump consists of a drive

cylinder, oil reservoir and electronics for either remote or manual

operation.

The electric motor for this pump is a 1.5 HP motor. Each electric

motor requires 115 VAC, 60 Hz input for normal operation. Amperage

draw for the electric motor at 10,0000 psi (68,951 kpa) is

approximately 13 amps. Reference Figure 5 for oil volume versus

pressure.

The hydraulic pump is equipped with a 3-way, 3- position manual

operated valve. This valve allows the operator to remotely control

the

advance

,

hold

and

return

functions of the rebar bender. A 15 ft.

(4.57 meters) remote control cable allows the operator to control the

pump remotely.

Figure 5. Oil Volume vs Pressure

Model PEW1501T Electric/Hydraulic Pump

0

50

100

150

200

250

300

350

400

450

0 1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Pressure(psi)

OilVolume (cu.in/min)