To Install (Figure 5)

1. Remove and discard the motor tie down strap and the

shipping block beneath the belt tension adjusting screw

(Not used on all models.)

2. Adjust motor adjusting screw for a belt deflection of

approximately 3/4" with five pounds of force applied midway

between the sheaves (refer to Figure 6a). Since the belt

tension will decrease dramatically after an initial run-in

period, it is necessary to periodically re-check the tension.

Excessive tension will cause bearing wear and noise.

3. The blower bearings are lubricated for life; however, before

initial unit operation the blower shaft should be lubricated at

the bearings with SAE 20 oil. This will reduce initial friction

and start the plastic lubricant flowing.

4. Make electrical connections according to the wiring

diagram.

5. Check rotation of the blower. Motor should be in clockwise

rotation when facing motor pulley. If rotation is incorrect,

correction should be made by interchanging wiring within

the motor. See wiring diagram on the motor.

6. The actual current draw of the motor should be determined.

Under no condition should the current draw exceed that

shown on the motor rating plate.

7. It is the installers responsibility to adjust the motor sheave

to provide the specified blower performance as listed on

pages 18 & 19 for blower settings different from the factory

set performance. The drive number on the unit may be

identified by referring to the Power Code number on the

serial plate of the unit (see page 26 for model number

nomenclature) and matching that number with those shown

on page 25. From the listing, the drive number can be

determined.

8. Blower sheave and motor sheave should be measured to

assure correct drive is on unit. Refer to page 26 for drive

sizes.

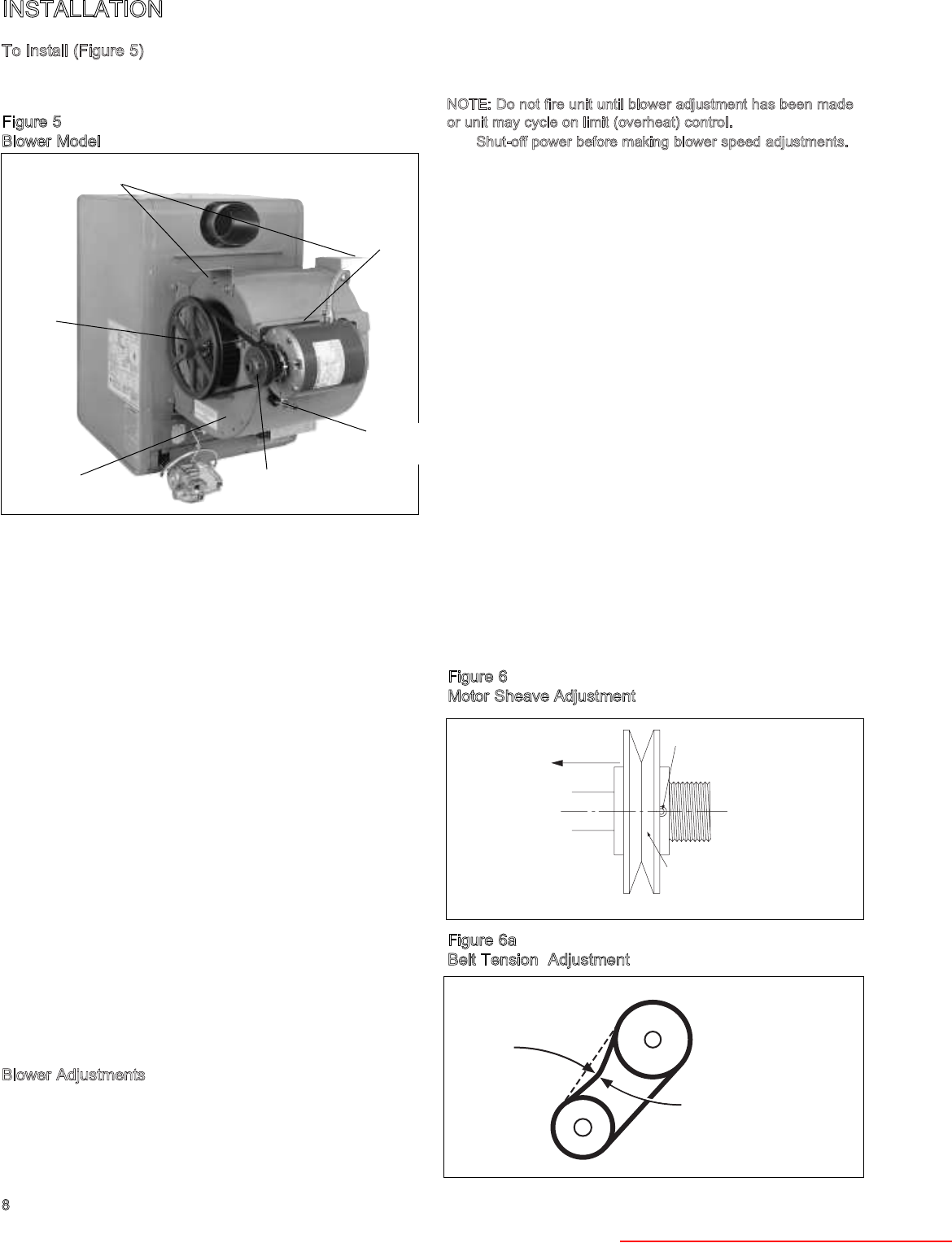

B

lower Adjustments

Following electrical connections, check blower rotation to

assure blow-through heating. If necessary interchange wiring to

reverse blower rotation. Start fan motor and check blower

sheave RPM with a hand-held or strobe-type tachometer. RPM

should check out with the speeds listed in Performance Data

shown on pages 18 and 19. A single-speed motor with an

adjustable motor sheave is supplied with these units. If blower

fan speed changes are required, adjust motor sheave as

follows:

N

OTE: Do not fire unit until blower adjustment has been made

or unit may cycle on limit (overheat) control.

1.

Shut-off power before making blower speed adjustments.

Refer to Determining Blower Speed on page 7 and to

Performance Date on pages 18 and 19 to determine

proper blower RPM.

2. Loosen belt and take belt off of motor sheave.

3. Loosen set screw on outer side of adjustable motor sheave

(see Figure 6).

4. To reduce the speed of the blower, turn outer side of motor

sheave counterclockwise.

5. To increase the speed of the blower, turn outer side of

motor sheave clockwise.

6. Retighten motor sheave set screw, replace belt and

retighten motor base. Adjust motor adjusting screw such

that there is 3/4” belt deflection when pressed with 5

pounds of force midway between the blower and motor

sheaves (see Figure 6a). Since the belt tension will

decrease dramatically after an initial run-in period, it is

necessary to periodically re-check the tension to assure

continual proper belt adjustment.

7. Check to make certain motor sheave and blower sheave

are aligned. Re-align if necessary.

8. Re-check blower speed after adjustment.

9. Check motor amps. Do not exceed amps shown on motor

nameplate. Slow blower if necessary.

10. Check air temperature rise across unit. Check temperature

rise against values shown in Performance Tables on

pages18 and19 to assure actual desired air flow is being

achieved.

11. If adjustments are required, recheck motor amps after final

blower speed adjustment.

8

TOWARD MOTOR

SET SCREW

ADJUSTABLE HALF

OF SHEAVE

3/4" DEFLECTION

WITH 5# FORCE

INSTALLATION

Figure 6

Motor Sheave Adjustment

Figure 6a

Belt Tension Adjustment

Figure 5

Blower Model

THREADED ROD MOUNTING

BRACKETS ON BLOWER ASSEMBLY

MOTOR

MOUNTING

BRACKET

BLOWER

SHEAVE

BLOWER

HOUSING

MOTOR

ADJUSTMENT

SCREW

MOTOR SHEAVE

Heater Parts from ACF Greenhouses