5

ADDITIONAL VENTING REQUIREMENTS FOR VENTING

INTO AN EXISTING MASONRY CHIMNEY OR COMMON

VENT (CATEGORY I and II UNITS ONLY)

1. Do not vent a Category I or II unit into a common vent with

mechanical draft systems operating under positive pressure

(Category III or IV units).

2. When connecting vent to an existing chimney, do not push

vent pipe beyond internal surface of chimney.

3. When venting into a common vent, the area of the common

vent should be equal to or greater than the area of the

largest vent plus 50 percent of the area of all additional

vents.

4. When venting into a common vent, the individual vents

should enter at different levels.

P

iping

1. Installation of piping must be in accordance with local

codes, and ANSI Z223.1, “National Fuel Gas Code,” or

CAN/CGA-B149 in Canada.

D

o not use flexible connectors

.

2. Piping to units should conform with local and national

requirements for type and volume and gas handled, and

pressure drop allowed in the line. Refer to Table 4, to

determine the cubic feet per hour (cfh) for the type of gas

and size of unit to be installed. Using this cfh value and the

length of pipe necessary, determine the pipe diameter from

Table 3. Where several units are served by the same main,

the total capacity, cfh, and length of main must be

considered. Avoid pipe sizes smaller than 1/2”. Table 3

allows for the usual number of fittings with a 0.3” W.C.

pressure drop. Where the gas supplied has a specific

gravity other than 0.60, apply the multiplying factor as given

in Table 2.

3. After threading and reaming the ends, inspect piping and

remove loose dirt and chips.

4. Support piping so that no strains are imposed on unit or

controls.

5. Use two wrenches when connecting piping to unit controls.

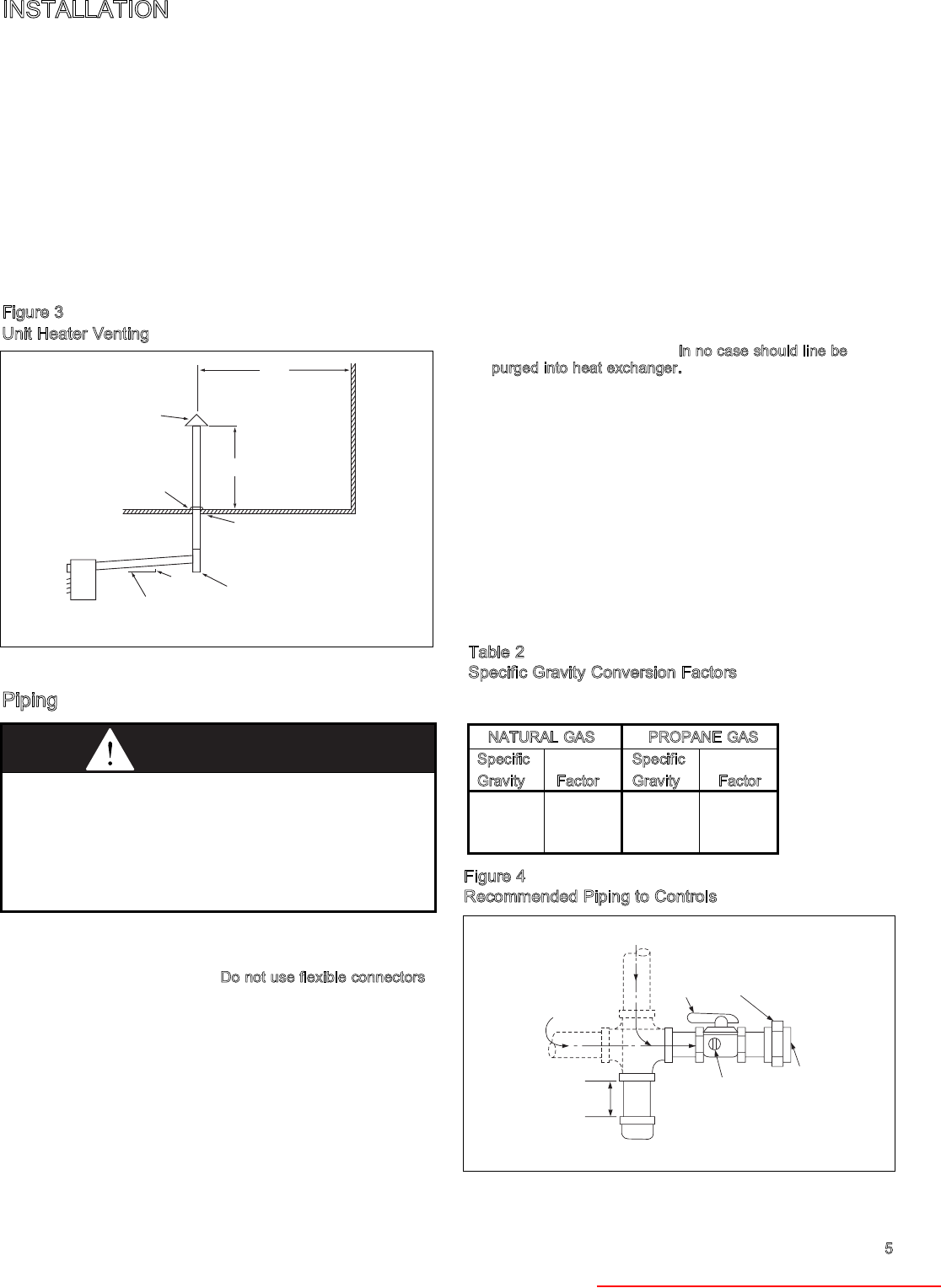

6. Provide a sediment trap before each unit and in the line

where low spots cannot be avoided. (See Figure 4).

7. Take-off to unit should come from top or side of main to

avoid trapping condensate.

8. Piping, subject to wide temperature variations, should be

insulated.

9. Pitch piping up toward unit at least 1/4” per 15’ of horizontal

run.

10. Compounds used on threaded joints of gas piping must be

resistant to action of liquefied petroleum gases.

11. Purge air before lighting unit by disconnecting pilot tubing

at combination gas control.

I

n no case should line be

purged into heat exchanger.

12. After installation, check system for gas leaks, using a soap

solution.

13. Install a ground joint union and a manual shut off valve

immediately upstream of the unit including a 1/8” NPT

plugged tapping accessible for test gage connection. (See

Figure 4).

14. Allow at least 5 feet of piping between any pressure

regulator and unit control string.

15. When Pressure/Leak testing, pressures above 14'' W.C.

(1/2 psi), close the field installed shut-off valve, disconnect

the appliance and its combination gas control from the gas

supply line, and plug the supply line before testing. When

testing pressures 14" W.C. (1/2 psi) or below, close the

manual shut-off valve on the appliance before testing.

GAS

SUPPLY LINE

GAS

SUPPLY LINE

GROUND

JOINT

UNION

MANUAL

SHUT-OFF

VALVE

3"

MIN.

SEDIMENT

TRAP

PLUGGED

1/8" NPT TEST

GAGE CONNECTION

TO

CONTROLS

CAUTION

Gas pressure to unit heater controls must never exceed 14"

W.C. (1/2 psi).

When leak testing the gas supply piping system, the

appliance and its combination gas control must be isolated

during any pressure testing in excess of 14" W.C. (1/2 psi).

The appliance should be isolated from the gas supply piping

system by closing its field installed manual shut-off valve

during any pressure testing of the gas supply piping system.

INSTALLATION

Figure 4

Recommended Piping to Controls

Table 2

Specific Gravity Conversion Factors

Multiplying factors to be used with Table 3 cubic ft./hr.values when the specific

gravity of gas is other than 0.60.

N

ATURAL GAS

Specific

Gravity Factor

0.55 1.04

0.60 1.00

0.65 0.962

PROPANE GAS

Specific

Gravity Factor

1.50 0.633

1.53 0.626

1.60 0.612

10' MIN.

TO WALL OR ADJOINING BUILDING

2'

MIN.

ROOF FLASHING

USE THIMBLE

THROUGH CEILING

APPROVED

TERMINAL

1'0"

SLOPE 1/4" TO

THE FOOT

UNIT

1/4"

DRIP LEG WITH

CLEANOUT CAP

*SIZE ACCORDING TO EXPECTED SNOW DEPTH.

*

Figure 3

Unit Heater Venting

Heater Parts from ACF Greenhouses