21

SERVICE INSTRUCTIONS – SAFETY DEVICES

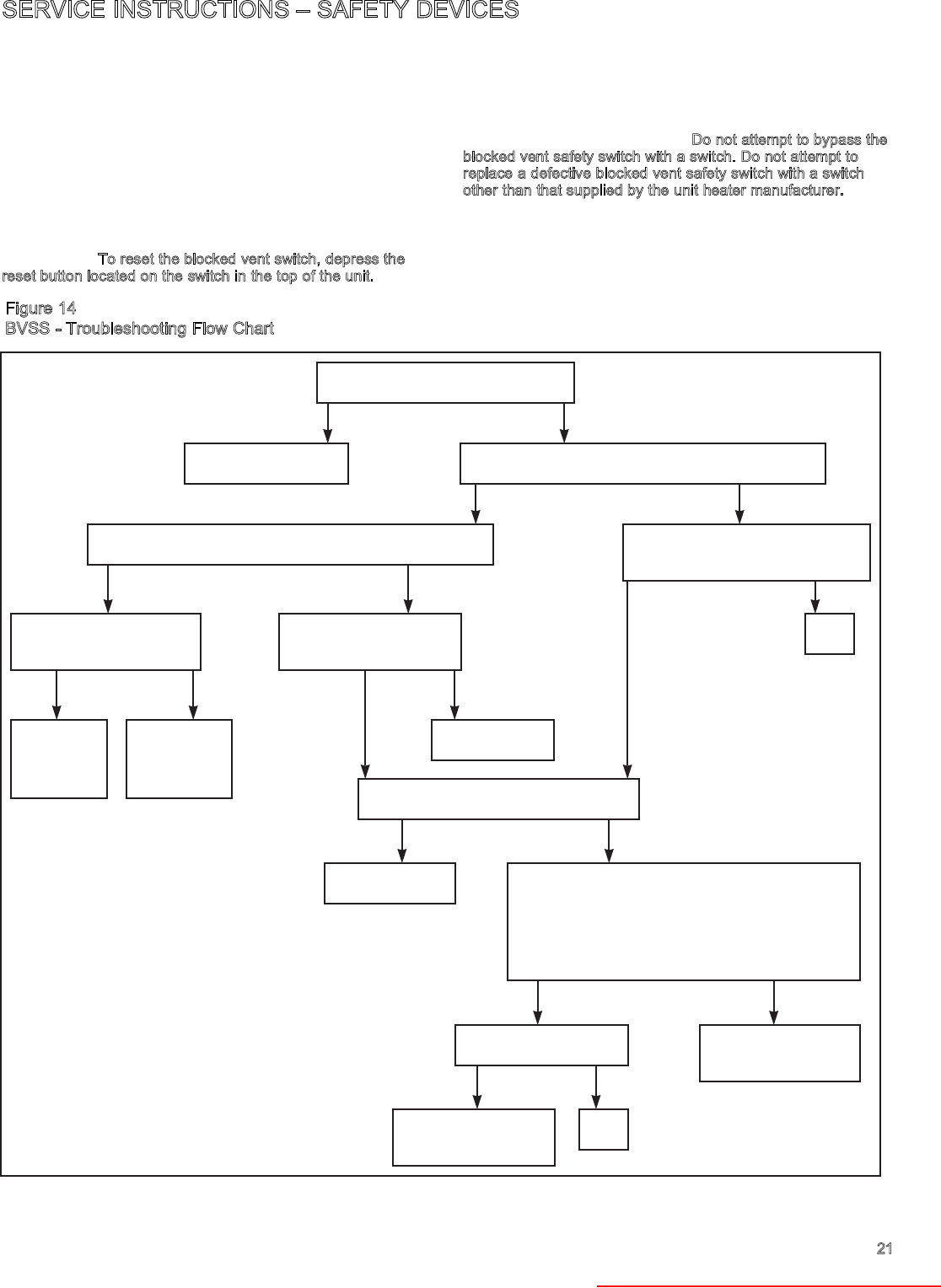

Figure 14

BVSS - Troubleshooting Flow Chart

If these changes do not stop the spillage or the installer

chooses not to make changes, a power exhauster is really the

only recommended fix (see bulletin 6-530).

Low ambient installations can also be a cause for extended

spillage. Be aware that in these installations for freeze

protection and/or condensate protection, there is a good

chance that a power exhauster will be necessary.

In instances where the blocked vent safety switch trips

repeatedly, refer to Figure 14.

After the vent system has been changed, or if no blockage or

damage is found in the vent system, the blocked vent switch

may be reset.

T

o reset the blocked vent switch, depress the

reset button located on the switch in the top of the unit.

With the switch reset, turn on the electric and gas supply to the

unit heater and restart the unit. Carefully observe the operation

of the unit to assure that it is operating correctly. If the block

vent switch does not allow the unit to function, or trips after the

unit has operated for a period of time, call a qualified service

agency to service the equipment.

D

o not attempt to bypass the

blocked vent safety switch with a switch. Do not attempt to

replace a defective blocked vent safety switch with a switch

other than that supplied by the unit heater manufacturer.

Is vent blocked or restricted?

Remove restriction

Is there spillage after 5 minutes? (see note 1)

Is there a negative pressure in building? (see note 2) Replace blocked vent switch;

Does switch still trip?

OK

Is vent in compliance

with NFGC?

Can negative pressure

be corrected?

Correct vent

Install

power vent

accessory

Correct

negative

pressure

Is unit overfired?

Reduce input

Can one or more of the following be done?

• Lengthen vertical vent run

• Insulate vent

• Use larger diameter vent

• Use less restrictive weather cap

OK

Install power

exhauster accessory

Does unit still trip?

Install power vent

accessory

YES

YES

YES

YES YES

YES

YES

YES

YES

NO NO

NO NO

NO

NO

NO

NO

NO

To determine spillage, place lit match

stick (6" - 8" match stick if possible) 2" - 3"

into diverter relief opening and determine

direction of the flame (or direction of

smoke if flame goes out). If flame or

smoke comes back at you, there is

spillage. The flame or smoke should be

pulled in.

One indication of negative pressure is

that outside doors tend to swing toward

inside of building.

Note 1:

Note 2:

Heater Parts from ACF Greenhouses