6

Wiring

All field installed wiring must be done in accordance with the

National Electrical Code ANSI/NFPA 70 – Latest Edition or

Canadian Electrical Code CSA C22.1 Part 1 or local codes.

Unit must be electrically grounded according to these codes.

See wiring diagram shipped with unit.

The power to these unit heaters should be protected with a

circuit breaker. Units for use with single-phase electric power,

should be provided with a manual motor starter, having

properly sized overload protection. Units for use with three-

phase electric power must be provided with a motor starter

having properly sized overload protection.

Location of thermostat should be determined by heating

requirements and be mounted on an inside wall about 5' above

floor level where it will not be affected by heat from the unit or

other sources, or drafts from frequently opened doors. See

instructions packed with thermostat.

I

nstallation of Blower Models (BD UNITS)

Attachment of Field Installed Ductwork, Blower

(BD) Models Only

Burned-out heat exchanger as well as shorter equipment life

will result from not providing uniform air distribution.

When installing heater always follow good duct design practices

for even distribution of the air across the heat exchanger.

Recommended layouts are shown below.When installing

blower units with ductwork the following must be done.

1.

P

rovide uniform air distribution over the heat exchanger.

Use turning vanes where required. See figures below.

2. Provide removable access panels in the ductwork on the

downstream side of the unit heater. These openings should

be large enough to view smoke or reflect light inside the

casing to indicate leaks in the heat exchanger and to check

for hot spots on exchanger due to poor air distribution or

lack of sufficient air.

3.

If ductwork is connected to the rear of the unit use Modine

blower enclosure kit or if using field designed enclosure

maintain dimensions of blower enclosure as shown on page 13.

INSTALLATION

CAUTION

Disconnect power supply before making wiring connections

to prevent electrical shock and equipment damage. ALL

UNITS MUST BE WIRED STRICTLY IN ACCORDANCE

WITH WIRING DIAGRAM FURNISHED WITH UNIT.

ANY WIRING DIFFERENT FROM WIRING DIAGRAM MAY

BE HAZARDOUS TO PERSONS AND PROPERTY.

Any damage to or failure of Modine units caused by incorrect

wiring of the units is not covered by MODINE’S STANDARD

WARRANTY (see Back Cover).

CAUTION

Proper air flow and distribution, across the heat exchanger

must be provided to prevent early failure of the blower unit

heater.

CAUTION

Do not attempt to attach ductwork of any kind to propeller PD

models.

CAUTION

Check for red heat exchanger tubes. If bottom of tubes

become red while blower unit is in operation, check for

proper air volume and air distribution. Adjust blower speed or

correct discharge duct design to correct problem.

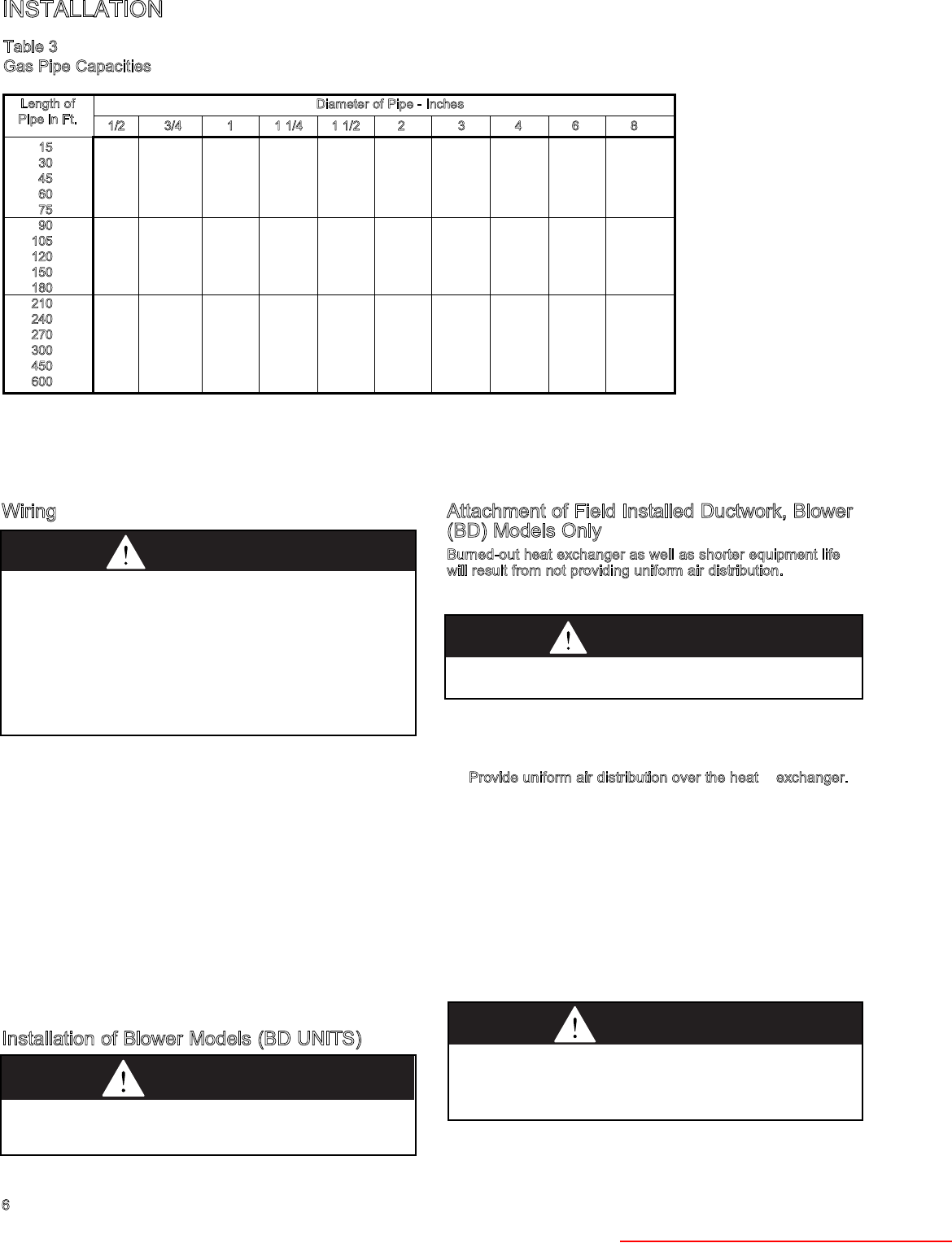

1/2 3/4 1 1 1/4 1 1/2 2 3 4 6 8

15

76 218 440 750 1220 2480 6500 13880 38700 79000

3

0

73 152 285 590 890 1650 4700 9700 27370 55850

45

44 124 260 435 700 1475 3900 7900 23350 45600

60

50 105 190 400 610 1150 3250 6800 19330 39500

75

97 200 345 545 1120 3000 6000 17310 35300

90

88 160 320 490 930 2600 5400 15800 32250

105

80 168 285 450 920 2450 5100 14620 29850

120

158 270 420 860 2300 4800 13680 27920

150

120 242 380 710 2000 4100 12240 25000

180

128 225 350 720 1950 4000 11160 22800

210

205 320 660 1780 3700 10330 21100

240

190 300 620 1680 3490 9600 19740

270

178 285 580 1580 3250 9000 18610

300

170 270 545 1490 3000 8500 17660

450

140 226 450 1230 2500 7000 14420

600

119 192 380 1030 2130 6000 12480

Table 3

Gas Pipe Capacities

In Cu. Ft.per Hour with Pressure Drop pf 0.3 in.W.C. with Specific Gravity 0.60.

Diameter of Pipe - Inches

Length of

Pipe in Ft.

Heater Parts from ACF Greenhouses