En-7

Whenrelocatingordisposingoftheairconditioner,pumpdownthesystemfollowingtheprocedurebelowsothatnorefrigerantisreleasedintotheatmos-

phere.

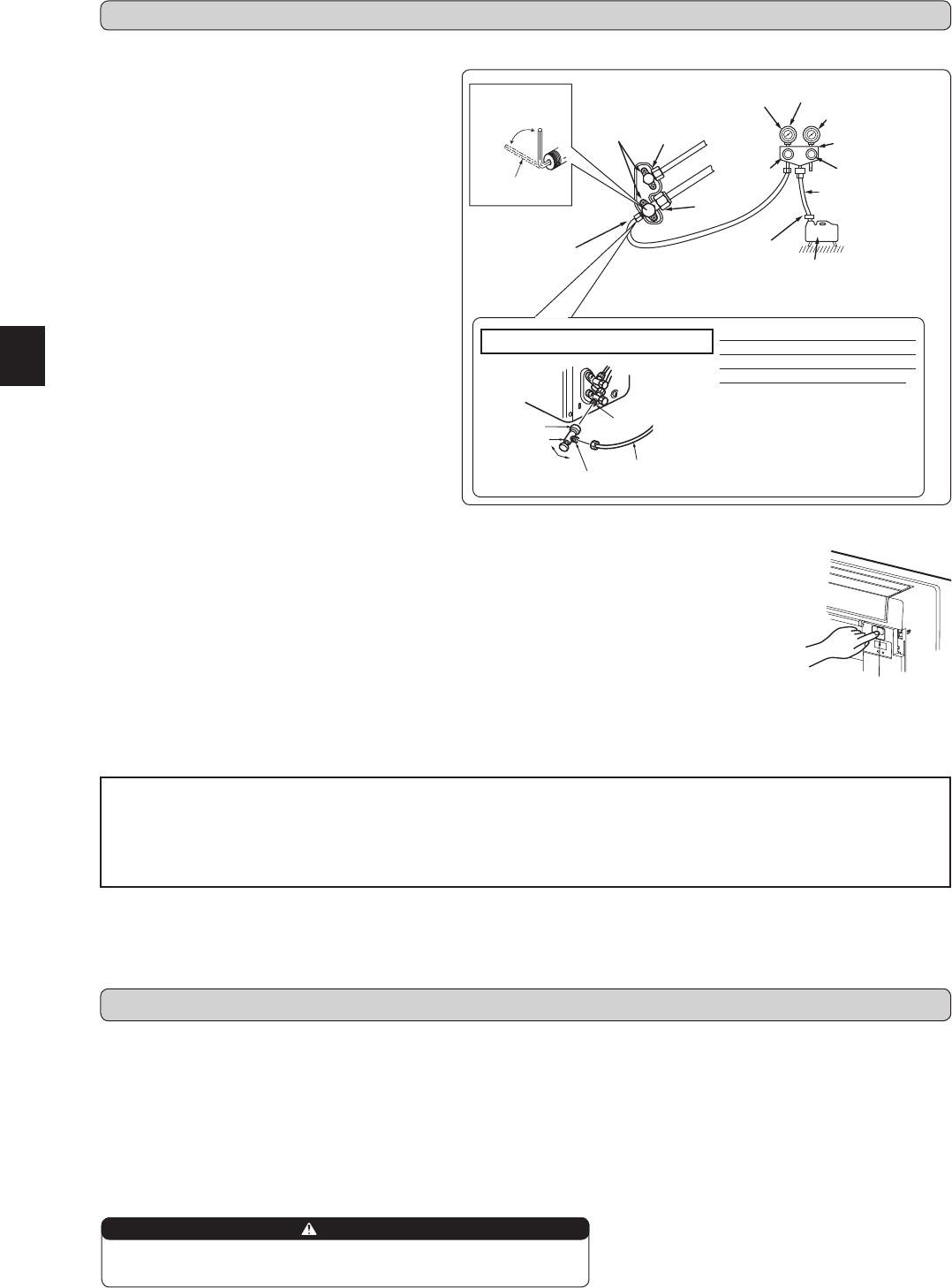

1)Connectthegaugemanifoldvalvetotheserviceportofthestopvalveonthegaspipesideoftheoutdoorunit.

2)Fullyclosethestopvalveontheliquidpipesideoftheoutdoorunit.

3)Closethestopvalveonthegaspipesideoftheoutdoorunitalmostcompletelysothatitcanbeeasilyclosedfullywhenthepressuregaugeshows0

MPa[Gauge](0kgf/cm

2

).

4)StarttheemergencyCOOLoperation.

TostarttheemergencyoperationinCOOLmode,disconnectthepowersupplyplugand/orturnoffthebreaker.After15seconds,connectthepower

supplyplugand/orturnonthebreaker,andthenpresstheE.O.SWonce.(TheemergencyCOOLoperationcanbeperformedcontinuouslyforupto

30minutes.)

5)Fullyclosethestopvalveonthegaspipesideoftheoutdoorunitwhenthepressuregaugeshows0.05to0MPa[Gauge](approx.0.5to0kgf/cm

2

).

6)StoptheemergencyCOOLoperation.

PresstheE.O.SWtwicetostoptheoperation.

5. PUMPING DOWN

4-4. EXPLANATION TO THE USER

• UsingtheOPERATINGINSTRUCTIONS,explaintotheuserhowtousetheairconditioner(howtousetheremotecontroller,howtoremovetheairl-

ters,howtoremoveorputtheremotecontrollerintheremotecontrollerholder,howtoclean,precautionsforoperation,etc.)

• RecommendtheusertoreadtheOPERATINGINSTRUCTIONScarefully.

Caution:

• Aftertestrunorremotesignalreceptioncheck,turnofftheunitwiththeE.O.SWortheremotecontrollerbeforeturningoffthepowersupply.Notdo-

ingsowillcausetheunittostartoperationautomaticallywhenpowersupplyisresumed.

To the user

• Afterinstallingtheunit,makesuretoexplaintheuseraboutautorestartfunction.

• Ifautorestartfunctionisunnecessary,itcanbedeactivated.Consulttheservicerepresentativetodeactivatethefunction.Refertotheservicemanual

fordetails.

4-3. AUTO RESTART FUNCTION

Thisproductisequippedwithanautorestartfunction.Whenthepowersupplyisstoppedduringoperation,suchasduringblackouts,thefunctionautomati-

callystartsoperationintheprevioussettingoncethepowersupplyisresumed.(Refertotheoperatinginstructionsfordetails.)

4-2. TEST RUN

Make sure the following is done.

•Panelisinstalledcorrectly.

•Indoorandoutdoorunitsareinstalledcorrectly,andpowerissupplied.

1)PresstheE.O.SWonceforCOOL,andtwiceforHEAToperation.Testrunwillbeperformedfor30minutes.Iftheleftlamp

oftheoperationindicatorblinksevery0.5seconds,inspecttheindoor/outdoorunitconnectingwire(A)formis-wiring.After

thetestrun,emergencymode(settemperature24ºC)willstart.

2)Tostopoperation,presstheE.O.SWseveraltimesuntilallLEDlampsturnoff.Refertooperatinginstructionsfordetails.

Checking the remote (infrared) signal reception

PresstheON/OFFbuttonontheremotecontroller(12)andcheckthatanelectronicsoundisheardfromtheindoorunit.Press

theON/OFFbuttonagaintoturntheairconditioneroff.

• Oncethecompressorstops,therestartpreventivedeviceoperatessothecompressorwillnotoperatefor3minutestopro-

tecttheairconditioner.

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN

Emergencyoperation

switch(E.O.SW)

When pumping down the refrigerant, stop the compressor before disconnecting

the refrigerant pipes. The compressor may burst if air etc. get into it.

WARNING

4-1. PURGING PROCEDURES AND LEAK TEST

Stopvalvefor

GAS

Stopvalvecap

(Torque19.6to

29.4N•m,200

to300kgf•cm)

Vacuumpump(orthevacuum

pumpwiththefunctionto

preventthebackow)

Gaugemanifoldvalve

(forR410A)

Compoundpressuregauge

(forR410A)

–

0.101MPa

(

–

760mmHg)

Handle

Low

HandleHigh

Adapterforpre-

ventingtheback

ow

Chargehose

(forR410A)

*Close

*Open

Hexagonalwrench

Precautionswhenusingthecontrolvalve

Whenattachingthecontrolvalveto

theserviceport,valvecoremayde-

formorloosenifexcesspressureis

applied.Thismaycausegasleak.

Serviceport

Body

Close

Open

Controlvalve

A

Whenattachingthecontrolvalveto

theserviceport,makesurethatthe

valvecoreisinclosedposition,and

thentightenpartA.Donottighten

partAorturnthebodywhenvalve

coreisinopenposition.

Serviceportcap

(Torque13.7to

17.7N•m,140to

180kgf•cm)

*4to5turns

1)Removeserviceportcapofstopvalveonthesideofthe

outdoorunitgaspipe.(Thestopvalvesarefullyclosedand

coveredincapsininitialstate.)

2)Connectgaugemanifoldvalveandvacuumpumptoserv-

iceportofstopvalveonthegaspipesideoftheoutdoor

unit.

3)Runthevacuumpump.(Vacuumizeformorethan15min-

utes.)

4)Checkthevacuumwithgaugemanifoldvalve,thenclose

gaugemanifoldvalve,andstopthevacuumpump.

5)

Leaveasitisforoneortwominutes.Makesurepointer

gaugemanifoldvalveremainsinthesameposition.Conrm

thatpressuregaugeshows–0.101MPa[Gauge](–760

mmHg).

6)Removegaugemanifoldvalvequicklyfromserviceportof

stopvalve.

7)Afterrefrigerantpipesareconnectedandevacuated,fully

openallstopvalvesonbothsidesofgaspipeandliquid

pipe.Operatingwithoutfullyopeninglowerstheperform-

anceandthiscausestrouble.

8)Referto1-3.,andchargetheprescribedamountofre-

frigerantifneeded.Besuretochargeslowlywithliquid

refrigerant.Otherwise,compositionoftherefrigerantinthe

systemmaybechangedandaffectperformanceoftheair

conditioner.

9)Tightencapofserviceporttoobtaintheinitialstatus.

10)Leaktest

Stopvalve

forLIQUID

Pressuregauge

(forR410A)

Chargehose

JG79A867H02_en.indd 7 2014/06/25 13:39:05