En-6

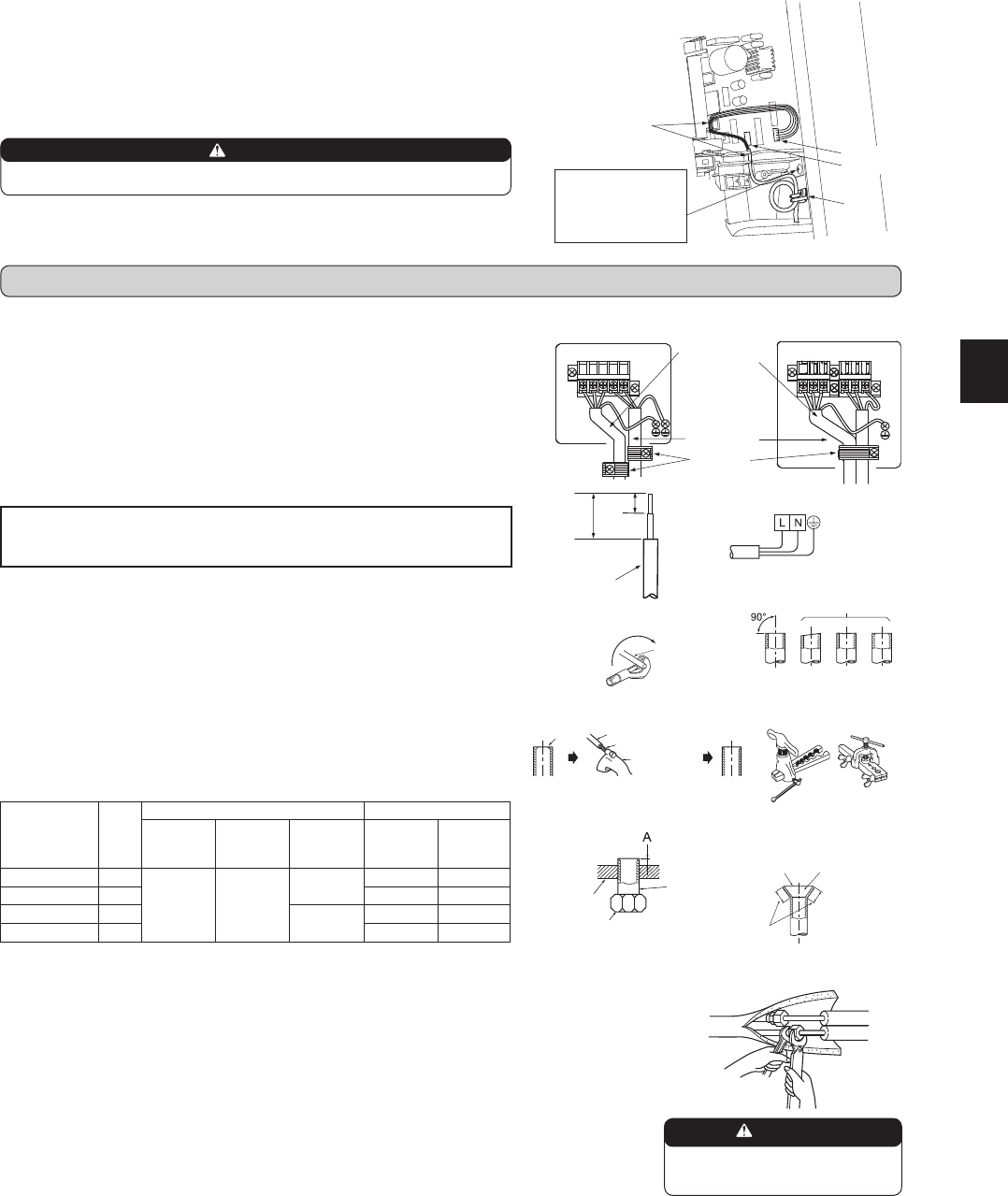

1)Removethepanel.

2)OpenthecoveroftheindoorcontrolP.C.board.

3)JointheconnectingcabletoCN105and/orCN104ontheindoorcontrolP.C.board.

4)Routetheconnectingcablethroughthispointinthegure.

5)Attachthecableclampprovidedwithinterface/connectorcabletothethickpartofthe

connectingcablewithascrew4×16asshowninthegure.

6)ClosethecoveroftheindoorcontrolP.C.board.Becarefulnottocatchthethinpart

oftheconnectingcableinthecover.Reinstallthepanel.

5)

4)

3)CN105

WARNING

Fix the connecting cable at the prescribed position securely.

Incorrect installation may cause electric shock, re, and/ or malfunction.

3. OUTDOOR UNIT INSTALLATION

3-2. FLARING WORK

1)Cutthecopperpipecorrectlywithpipecutter.(Fig.1,2)

2)Completelyremoveallburrsfromthecutcrosssectionofpipe.(Fig.3)

•Puttheendofthecopperpipetodownwarddirectionasyouremoveburrsin

ordertoavoidtoletburrsdropinthepiping.

3)Removearenutsattachedtoindoorandoutdoorunits,thenputthemonpipehaving

completedburrremoval.(Notpossibletoputthemonafteraringwork.)

4)Flaringwork(Fig.4,5).Firmlyholdcopperpipeinthedimensionshowninthetable.

SelectAmmfromthetableaccordingtothetoolyouuse.

5)Check

•ComparethearedworkwithFig.6.

•Ifareisnotedtobedefective,cutoffthearedsectionanddoaringworkagain.

3-3. PIPE CONNECTION

• Fastenarenutwithatorquewrenchasspeciedinthetable.

• Whenfastenedtootight,arenutmaybreakafteralongperiodandcauserefrigerantleakage.

• Besuretowrapinsulationaroundthepiping.Directcontactwiththebarepipingmayresultinburnsor

frostbite.

Indoor unit connection

Connectbothliquidandgaspipingstoindoorunit.

• Applyathincoatofrefrigerationoil(J)onthearedendsofthepipes.Donotapplyrefrigerationoilon

screwthreads.Excessivetighteningtorquewillresultindamageonthescrew.

• Forconnection,rstalignthecenter,thentightentherst3to4turnsofarenut.

• Usetighteningtorquetableaboveasaguidelineforindoorunitsideunionjointsection,andtightenusing

twowrenches.Excessivetighteningdamagesthearesection.

Outdoor unit connection

Connectpipestostopvalvepipejointoftheoutdoorunitinthesamemannerappliedforindoorunit.

• Fortightening,useatorquewrenchorspannerandusethesametighteningtorqueappliedforindoorunit.

3-4. INSULATION AND TAPING

1)Coverpipingjointswithpipecover.

2)Foroutdoorunitside,surelyinsulateeverypipingincludingvalves.

3)Usingpipingtape(G),applytapingstartingfromtheentryofoutdoorunit.

•Stoptheendofpipingtape(G)withtape(withadhesiveagentattached).

•Whenpipinghavetobearrangedthroughaboveceiling,closetorwherethetemperatureandhumidity

arehigh,windadditionalcommerciallysoldinsulationtopreventcondensation.

Pipediameter

(mm)

Nut

(mm)

A(mm) Tighteningtorque

Clutchtype

tool

forR410A

Clutchtype

tool

forR22

Wingnut

typetool

forR22

N•m kgf•cm

ø6.35(1/4”) 17

0to0.5 1.0to1.5

1.5to2.0

13.7to17.7 140to180

ø9.52(3/8”) 22 34.3to41.2 350to420

ø12.7(1/2”) 26

2.0to2.5

49.0to56.4 500to575

- - - -

Copper

pipe

Good

TiltedUnevenBurred

Nogood

Fig.1 Fig.2

Burr

Copperpipe

Sparereamer

Pipecutter

Clutchtype

Flaringtool

Fig.4

Fig.3

Smoothall

around

Evenlength

allaround

Insideisshining

withoutany

scratches.

Flarenut

Die

Fig.5

Fig.6

Copper

pipe

Wingnuttype

WARNING

When installing the unit, securely

connect the refrigerant pipes before

starting the compressor.

3-1. CONNECTING WIRES FOR OUTDOOR UNIT

1)Opentheservicepanel.

2)Loosenterminalscrew,andconnectindoor/outdoorunitconnectingwire(A)fromthe

indoorunitcorrectlyontheterminalblock.Becarefulnottomakemis-wiring.Fixthe

wiretotheterminalblocksecurelysothatnopartofitscoreisappeared,andnoex-

ternalforceisconveyedtotheconnectingsectionoftheterminalblock.

3)Firmlytightentheterminalscrewstopreventthemfromloosening.Aftertightening,

pullthewireslightlytoconrmthattheydonotmove.

4)Connectpowersupplycord(K).

5)Fixindoor/outdoorunitconnectingwire(A)andpowersupplycord(K)withthecord

clamp.

6)Closetheservicepanelsecurely.

• Makeearthwirealittlelongerthanothers.(Morethan100mm)

• Forfutureservicing,giveextralengthtotheconnectingwires.

• Besuretoattacheachscrewtoitscorrespondentterminalwhensecuringthecordand/or

thewiretotheterminalblock.

Terminalblock

Cordclamp

Terminalblock

Powersupply

cord(K)

15mm

35mm

Leadwire

<KJ25,35>

<KJ50,60>

Indoor/outdoor

unitconnecting

wire(A)

Power supply

cord (K)

Whenmountingthe

interfaceandthe

connectorcable,use

thisscrewtoxthe

connectingcable.

3)CN104

JG79A867H02_en.indd 6 2014/06/25 13:39:04