18

NOTE: DIAGRAMS & ILLUSTRATIONS NOT TO SCALE.

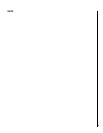

Figure 34

Step 9. Reassemble the remaining compo-

nents by reversing the procedures outlined in

the preceding steps. Use pipe joint compound

or Teflon tape on all pipe fittings before install-

ing (ensure propane resistant compounds are

used in propane applications, do not use pipe

joint compounds on flare fittings).

Step 10. Attach the conversion label provided

in the conversion kit to the rating plate on the

appliance.

Figure 35

shows all of the labels for

all of the kits covered by this manual as shown

in the tables on page 17. Compare the label

provided in the kit being installed to the appro-

priate label shown in

Figure 35

.

Step 11. Turn on the gas supply and test for

leaks as shown in

step 5 on page 11

.

Figure 35

All Models

Step 8.

(Refer to Figure 29 )

A. Remove the orifice from the manifold

and replace it with the one provided in the

kit. See the following table for orifice

sizes for natural and propane models

.

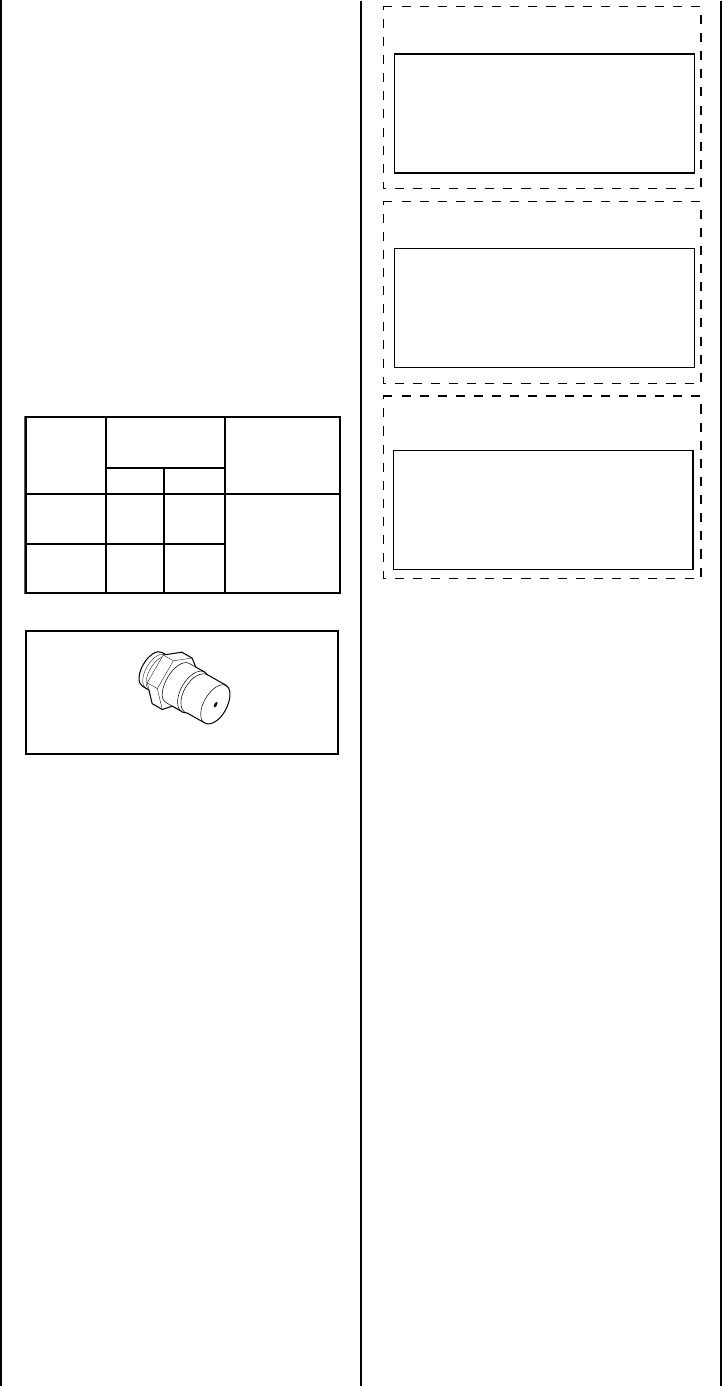

Figure 34

illustrates the orifice.

B. Install the burners as shown in

Figure 29

.

The primary air opening can be adjusted

by removing the venturi tube air shutter

securing screw and placing it in the other

hole provided nearby. The correct hole

usage for this screw for the gas being

used can be determined by the air shutter

gap indicated in

Figure 25 on page 14.

ledoM

.oN

ezisecifirO

noitavelE

teeF

)sretem(

.taN.porP

TSVBE

FPVBE

23#05#

0054-0

)2731-0(

RCVBE

LCVBE

43#05#

THIS APPLIANCE HAS BEEN CONVERTED TO:

NATURAL GAS

INPUT BTU/HR – 37,500

MANIFOLD PRESSURE – 3.5"

ORIFICE SIZE – #32

Kit Catalog No.

H2199 and H2201

Kit Catalog No.

H2198 and H2200

THIS APPLIANCE HAS BEEN CONVERTED TO:

PROPANE/LPG

INPUT BTU/HR – 34,000

MANIFOLD PRESSURE – 10.0"

ORIFICE SIZE – #50

THIS APPLIANCE HAS BEEN CONVERTED TO:

NATURAL GAS

INPUT BTU/HR – 34,000

MANIFOLD PRESSURE – 3.5"

ORIFICE SIZE – #34

Kit Catalog No.

H2203 and H2205