mini HE

mini HE C24 G.C. appliance No. 47---348---38

mini HE C28 G.C. appliance No. 47---348---39

mini HE C32 G.C. appliance No. 47---348---41

Destination countries: GB, IE

INTRODUCTION

mini HE are wall mounted, room sealed, condensing, low

water content combination gas boilers featuring full sequence

automatic spark ignition and fan assisted combustion.

SAFETY

Current Gas Safety (Installation & Use)

Regulationsorrulesinforce

In your own interest, and thatof safety, it isthe law that thisboiler

must be installed by a CORGI registered installer o r in IE a

competent person, in accordance with the above regulations.

It is essential that the instructio ns in this boo klet are strictly

followed, for safe and economical operation of the boiler.

ELECTRICITY SUPPLY

Theappliancemustbeefficientlyearthed.

Supply 230 V 50 Hz. The fusing should be 3 A.

Connection must be made i n a way that allows complete

isolation of the electric al supply, suc h as a double pole s witch,

having a 3 mm (1/8”) co ntact separ ation in both poles, or a

plug and soc ket serving only the boiler and syst em controls.

The means of isolation must be accessible to the user after

installation.

IMPORTANT NOTES

F This appliance must no t be operated without the casing

correctly fitted and forming an adequate seal.

F If the boiler is installed in a compartment then the

compartment MUST NOT be used for storage purposes.

F Under no circumstances should any of the sealed

components on this appliance be used incorrectly or

tampered with.

F If it is known or suspected that a fault exist on the boiler

then it MUST NOT BE USED until the fault has been

corrected by a CORGI registered installer or in IE a

competent person.

MINIMUM CLEARANCES

Clearances of 200 mm (7 7/8“) above and below, 25 mm (1“)

at left, 50 mm (2“) at right and 450 mm (17 3/4“) at the front of

theboilercasemustbeallowedforservicing.

After installation the following clearances are allowable during

use, providing the encasing parts are removeable for servicing:

The bottom clearance can be reduced to 20mm (3/4”).

The front clearance can be reduced to 50mm (2”).

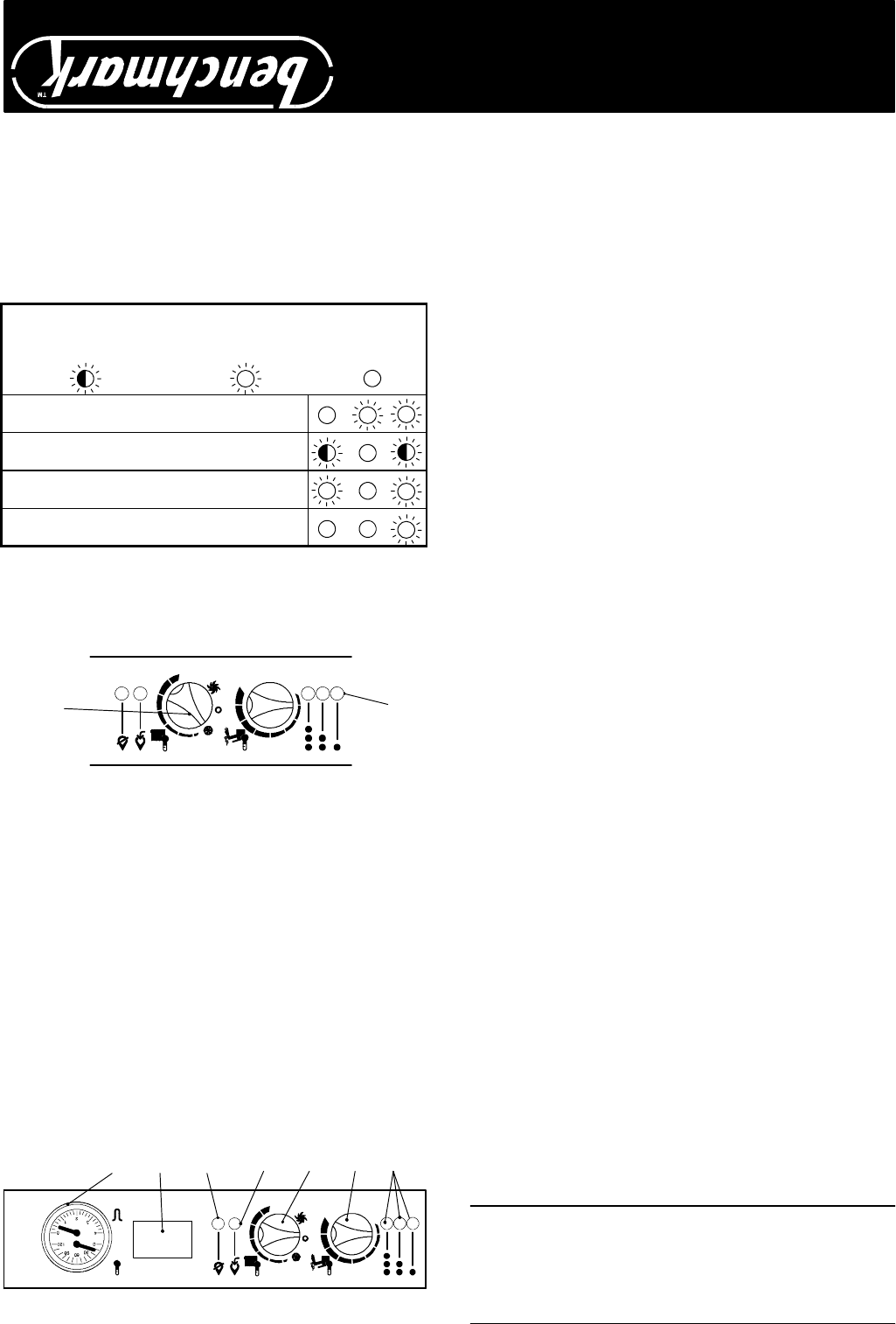

BOILER CONTROLS

BCD EF

G

A

A Appliance operation lights

B Domestic hot water temperature control

C Main switch and radiator temperature control

D Boiler reset button

E Lock---out signal lamp

F Programmer (optional)

G System pressure and temperature gauge

TO LIGHT THE BOILER

1 Check that the valves located in the lower part of the boiler

are open.

2 Switch the el ectricity supply on.

The appliance operation light A will flash every 4 seconds

(stand---by condition).

3 If the boiler is to be used for CH and DHW position the

main switch as in the following illustration.

The appliance operation light A will flash every 2 seconds

(operating boiler).

C

A

DIAGNOSTIC LIGHTS

The following table gives a summary of the relationship

between each of the possible light combinations and their

meaning during normal operaion of the boiler

Normally operating boiler

CH operation

DHW operation

F rost protect operation

Lamp

OFF

Flashing lamp, alone

or simultaneously

with an other lamp.

Flashing lamp,

alternate with

another lamp.

If the lights sequence observed on the boiler is not incl uded

above then a fault is indicated.

Reference should be made to the Installation Instructions or

consult a CORGI registered installer.

THE BENCHMARK SERVICE INTERVA L RECORD MUST BE COMPLETED AFTER EACH SERVICE

Caradon Ideal Limited is a member of the Benchmark initiative and fully supports the

aims of the programme. Benchmark has been introduced to improve the sta ndards of

installation and c ommissioning of central heating systems in the UK a nd to e ncourage

the regular servicing of all central heating systems to ensure safety and efficiency.

All CORGI registered installers carry a CORGI ID card, and have a registration number. Both should be record ed in the Benchmark

Commissioning Checklist. You can check your i nst aller by calling CORGI direct on 01256 372300.