INSTALLATION

mini HE --- Installation & Servicing

17

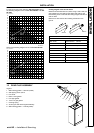

For the correct use of the restrictors with twin pipes refer to

the following diagram for the models mini HE C24,andmini

HE C28.

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

0 2 4 6 8 101214161820222426283032

Restrictor

50 mm

Allowed values

Flue exhaust ”a”

Air intake ”b”

Restrictor

55 mm

Refer to the following diagram for the model mini HE C32.

0

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

0 2 4 6 8 101214161820222426283032

Restrictor

50 mm

Allowed values

Flue exhaust ”a”

Air intake ”b”

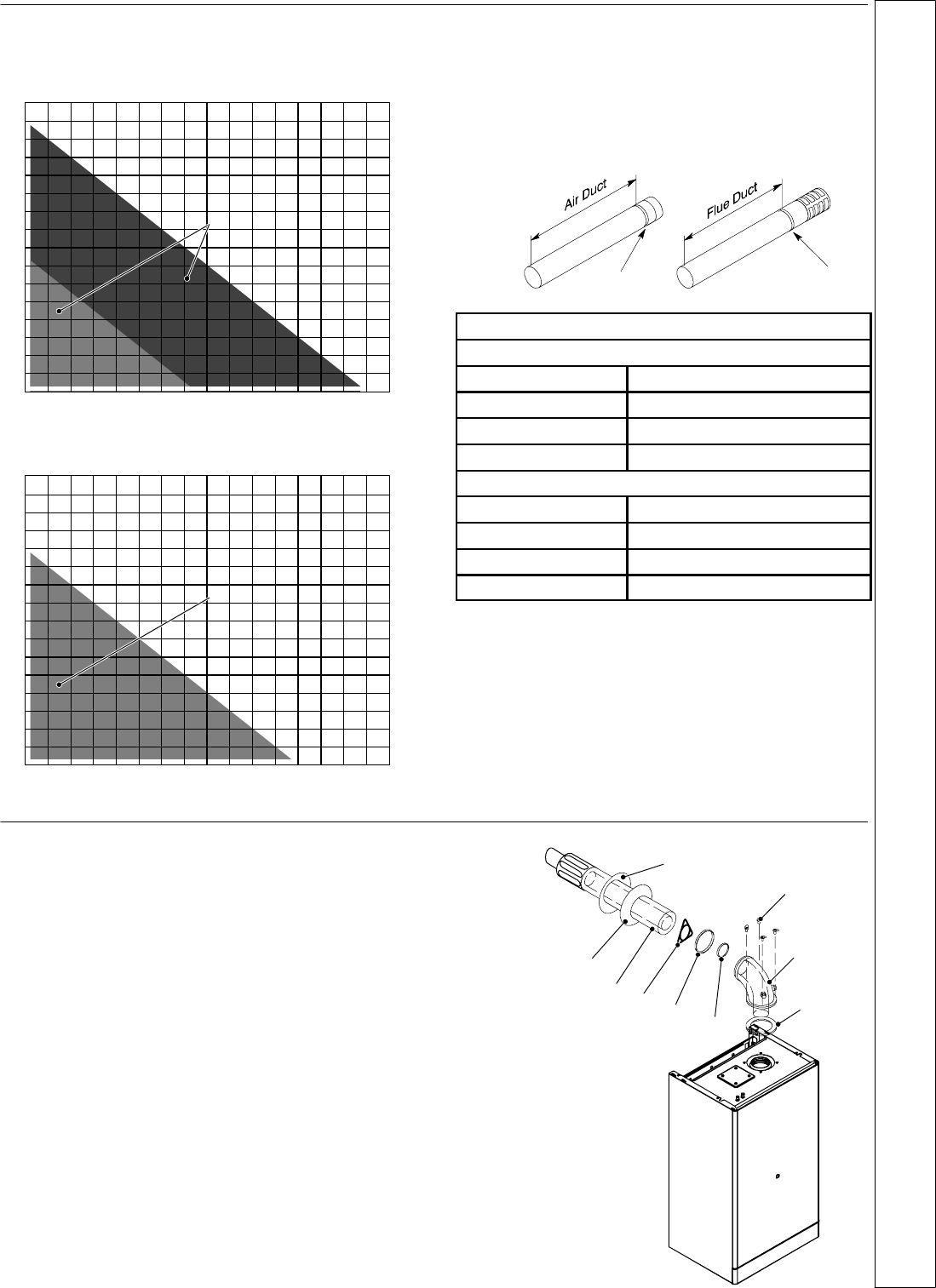

Cutting lengths of flue and air ducts

Measure the wal l thickness and, when using a side outlet, the

gap between the inner wall and the boiler side casing. Use

the following chart to calculate the cutting lengths of both flue

and air ducts.

Marktheairductandflueduct making reference on the

groove.

Groove

Groove

Twin Pipe

Air duct

Rear Outlet W all thickness + 130 mm

Rear outlet+Stand---off Wall thickness + 165 mm

Side Outlet --- RH Wall thickness + Gap + 187 mm

Side Outlet --- L H Wall thickness + Gap + 93 mm

Flue Duct

Rear Outlet W all thickness + 130 mm

Rear outlet+Stand---off Wall thickness + 165 mm

Side Outlet --- RH Wall thickness + Gap +67 mm

Side Outlet --- L H Wall thickness + Gap + 213 mm

12 REAR FLUE ASSEMBLY

Legend

1 Wall finishing gasket --- external (rubber)

2 Self tapping screw 4,2x13

3 F lue turret

4 Boiler---turret gasket

5 Fluepipegasket

6 Turret---air pipe gasket

7 Centring spring

8 A ir/flue pipe with terminal grille assembly

9 Wall finishing gasket --- internal (plastic)

1

8

9

7

6

5

4

3

2

INSTALLATION