INSTALLATION

mini HE --- Installation & Servicing

32

38 GENERAL CHECKS

Make the following checks for correct operation:

1Hotwater.

a. Fully open all D HW taps in turn and ensure that water flows

freely from them.

b. Close all taps except the furthest one from the boiler and

check that the boiler is fir i ng at maximum rate.

c. Ensure that DHW temperature of approximately 35 ûCrise

is obtained at the tap. This corresponds to a flow rate of about

litres/min (gpm)

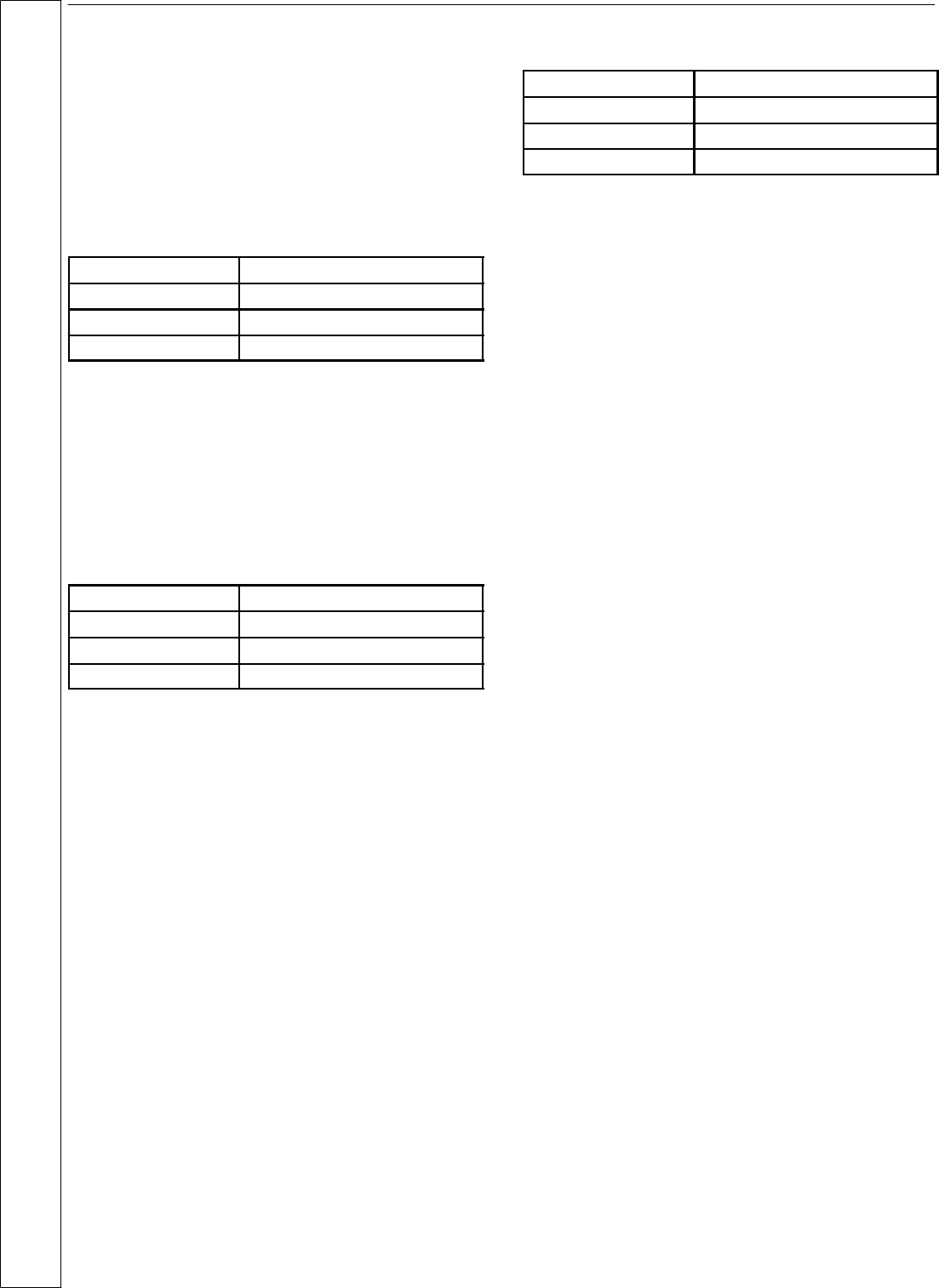

models

10.1 (2.2) mini HE C24

11.7 (2.6) mini HE C28

13.1 (2.9) mini HE C32

d. Turn off the DHW tap.

2 Central heating (all models)

Operate each control separately and check that the main

burner or circulating pump, as the case may be, responds.

3Gasrate---G20

Check the boiler gas rate when the boiler is at full output .

The gas rate checked at the gas meter, with no other

appliance in use will normally be:

litres/min (ft

3

/min) models

44.2 (1.56) mini HE C24

51.2 (1.81) mini HE C28

58.8 (2.08) mini HE C32

If this check is not possible, ensure that the burner pressure

is:

mbar (in. w.g.)

models

10.8 (4.3) mini HE C24

10.0 (4.0) mini HE C28

13.0 (5.2) mini HE C32

4 Water c i r culation system

Note. Fer nox Superfloc flushing solution should be used

during the flushing procedure.

a. With the system HOT examine all water connections for

tightness.

b. With the system still HOT, turn off the gas, water and

electricity supplies to the boiler and drain down, to complete

the flushing process.

c. Refill the system, adding inhibitor (see ’Water Treatment’), if

required.

Vent as necessary to clear all air and, again, check for wat er

tightness. After venting, repressurise as required.

d. Balance t he system. It is suggested that , i nitially, all radiator

handwheel valves (or TRVs if fitted) be set fully open, that all

lockshield valves be set a half---turn open.

Make minor adjustments to each radiator to achieve the same

differential on all.

5Fluesystem

Check the integrity of the flue outlet and air inlet system to the

boiler ensuring no leaks are evident from piping joints or

flue/air sampling points .

Finally, set the system cont rols to the us ers requirements.

If an optional programmer kit is fitted refer to the instructions

supplied.

INSTALLATION