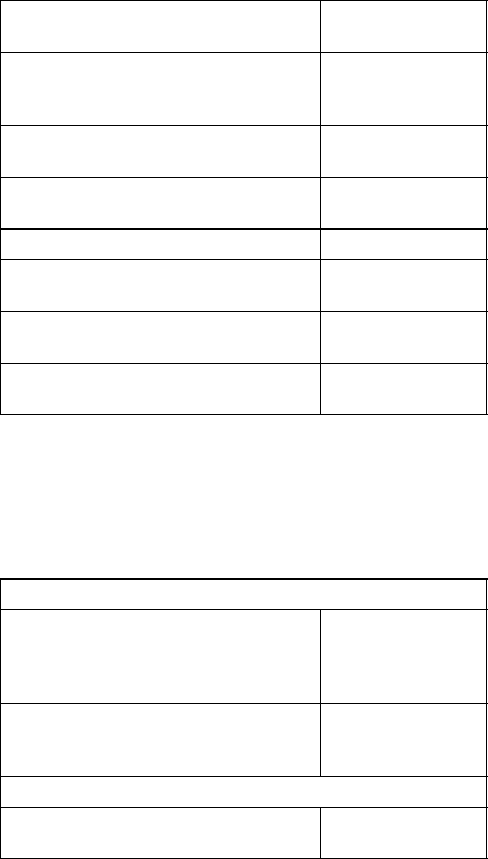

GENERAL

mini HE --- Installation & Servicing

9

5 From vertical drain pipes or soil

pipes*

25 mm ( 1”) ***

6 From an internal or external corner

or to a boundary along side the

terminal

25 mm ( 1”) ***

7 Above adjacent ground, roof or

balcony level

300 mm (12”)

8 From a surface or a boundary

facing the terminal.

600 mm (24”)

9 From a terminal facing a terminal 1200 mm (48”)

10 From an opening in a car port (e.g.

door or window) into dwelling

1200 mm (48”)

11 Vertic ally from a terminal on the

same wall

1500 mm (60”)

12 Horizontal ly from a terminal on the

wall

300 mm (12”)

* If the terminal is within 150mm of any vertical soil or drain

pipe, an aluminium shield at least 400mm (15 3/4”) long

should be fitted equi---distant from the terminal and close to

the pipe.

*** Only 1 spacing down to 25mm is allowable per

installation.

Vertical Terminals

13 Above the roof pitch with roof

slope of all angles.

Above flat roof

300 mm (12”)

300 mm (12”)

14 From single wall face

From corner wall faces

600 mm (24”)

1000 mm (40”)

Twin Flue Applications

15 Centre distance between air inlet

and flue outlet ducts

120mm (5”) **

** Where the twin flue ducts are positioned at or near the above

minimum centres the wall sealing gaskets should be trimmed to

allow them to fit f lat to the wall. This should b e d o ne for both in-

side and outside wall gaskets

Terminals guards are available from boiler suppliers --- ask for

Tower Flue Guard, Model K6. In case of difficulty seek advice

from:

Grasslin UK Ltd.,Tower house, Vale Rise, Tonbridge,

Kent TN9 1TB Tel. +44 (0) 1732 359 888 Fax No. +44 (0)

1732 354 455 www.tfc---group.co.uk

IMPORTANT It is absolutely ESSENTIAL to ensure, in

practice, that products of combustion discharging from the

terminal cannot re---enter the building or any other adjacent

building through ventilators, windows, doors other sources of

natural air infiltration, or forced ventilation / air conditioning.

If this should occur the appliance MUST be turned OFF,

labelled as “uns afe” unt il corrective actio n t aken.

AIR SUPPLY

It is NOT necessary to have a purpose---provided air vent in

the room or internal space in which the boiler is installed.

Neither is it necessary to ventilate a cupboard o r

compartment in which the boiler is installed, due to the low

surface temperatures of the boiler casing during operation;

therefore the requirements of BS6798, Clause 12, BS 5440:2

and in IE I.S. 813:2002 may be disregarded.

WATER CIRCULATION SYSTEM

The boilers are designed for connection to pressurised, fully

pumped, sealed water central heating systems ONLY. The

domestic hot water (DHW) calo rifier is incor porated within the

combi boiler and only requires co nnection to the mains water

supply.

Additional Pumps.

The boiler is supplied with an integral cir culating pump. If the

boiler is to be used in conjunction with any additional

circulating pumps, please c ontact the Technical Helpline for

advice on application.

IMPORTANT

A minimum length of 1m of copper pipe MUST be fitted to

both flow and return connections from the boiler before

connec tion to any plastic piping.

Ensure that the mains water supply pressure is adequate to

provide the required DHW flow rate. Refer to Table 1 on

page 4.

The central heating system should be in accordance with BS.

6798 and, in addition, for smallbore and microbore systems

BS. 5449.

The domestic hot water system should be in accordance with

BS. 5546 and BS. 6700.

Copper tubing to BS 2871:1 is recommended for water

carrying pipework and MUST be used for pipework carrying

potable water.

Any soldered joints on potable water pipework MUST NOT be

made with solder containing lead.

Ancillary pipework not forming part of the useful heating

surface should be lagged to prevent heat loss and any

possible freezing --- particularly where pipes run through roof

spaces or ventilated underfloor spaces.

Draining taps should be at least 1/2” BSP nominal size and

be in accordance with BS 2879.

WA TER TREATMENT

Central Heating

Antifreeze fluid, corrosion and scale inhibitor fluids suitable for

use with boilers having copper heat exchangers may be used

in the central heating system.

IMPORTANT

The application of any other treatment to this product

may render the guarantee of Caradon Ideal Limited

INVALID .

Caradon Ideal Limited recommend Water Treatment in

accordance with the Benchmark Guidance Notes on Water

Treatment in Central Heating Systems.

Caradon Ideal Limited recommend the use of Fernox , GE

Betz Sentinel or Salamander water treatment products, which

must be used in acc ordance with the manufacturers

instructions.

Notes.

1. It is most important that the correct concentration of the

water treatment products is maintained in accordance with

the manufacturers’ instructions.

2. If the boiler is installed in an existing system any unsuitable

additives MUST be removed by thorough cleansing.

BS 7593:2006 details the steps necessary to clean a

domestic heating system.

3. In hard water areas, treatment to prevent lime scale may be

necessary --- however, the use of artificially softened water is

NOT permitted.

4. Under no circumstances should the boiler be fired before

the system has been thoroughly flushed.