INSTALLATION

mini HE --- Installation & Servicing

31

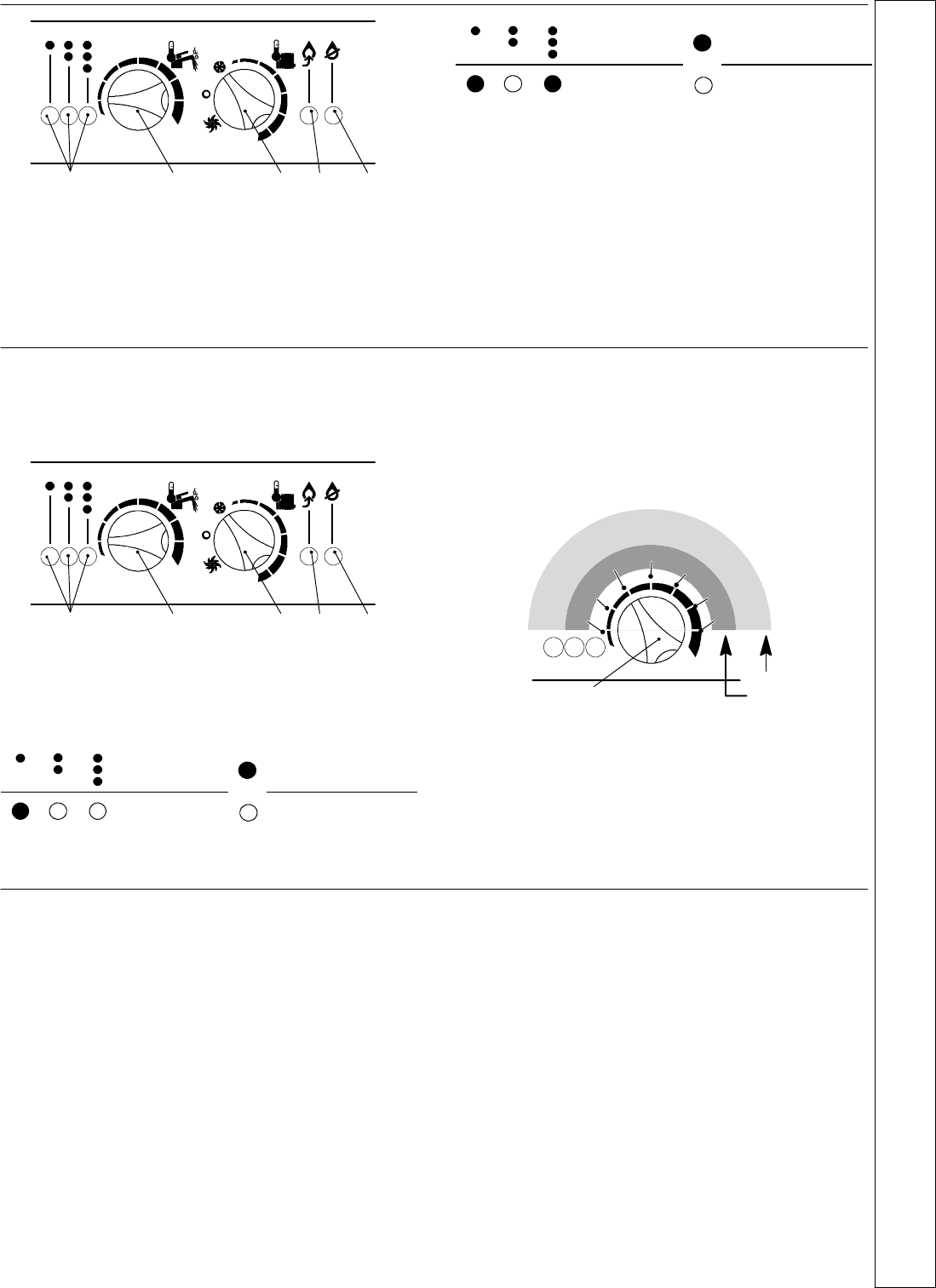

CA DEB

12 Press and hold the reset button D for about 10 seconds

until the lock---out signal lamp E blinks.

13 Press the reset button D repeatedly (4 times) until the

lamps A give the follow indication:

Where:

Lamp ON

Lamp OFF

14 Turn the DHW temperature control B to the minimum (fully

counterclockwise) and then on the pos ition noted on step

10. By turning the control B the lock---out signal lamp E

blinks quickly (2 per second) indicating that the setting

has changed and must be memorized.

15 To memorize the setting press and hold the reset button D

for about 5 seconds until the lamps A briefly blink

simultaneously.

16 To reset the boiler to the normal operation turn it off and

on by the main switch C checking the ignition pressure

and that the burner lights up unifo rmly. The boiler

automatically resets to its normal operation after 10

minutes if the above reset operation is not performed.

36 ANTI CYCLING SETTING

It is possible to set the minimum delay time that must pass

between two ignitions of the burner in c .h. function mode.

1 Turn the boiler on positioning the main switch C as follow:

CA DEB

2 Press and hold the boiler reset button D for a bout 10

seconds until the lock---out signal lamp E blinks

3 The lamps A should give the indication as in next figure

(reignition frequency). If not, press the reset button D

repeatedly to obtain it.

Where:

Lamp ON

Lamp OFF

At this time it is possible to determine the current setting by

keeping the reset button D pressed for more than 5 seconds.

The lamps A will flash a number of times corresponding to the

setting.

4 To c hange the setting turn the DHW temperature control B

to a position corresponding to the desired delay. By

turning the control B, the lock---out signal lamp E blinks

quickly (2 per s econd) indicating that the setting has

changed and must be memorized.

1

4

2

3

5

6

7

0

11/2

3

4

51/2

7

81/2

B

Setting No.

Delay (minutes)

5 To memorize the setting press and hold the r eset button D

for about 5 seconds until the lamps A briefly blink

simultaneously.

6 To r eset the boiler to the normal operation turn it off and

on by the main switch C. The boiler automatically resets to

its normal operation after 10 minutes if the above reset

operation is not performed.

The factory setting anti cycling time is 3 minutes.

37 COMMISSIONING AND TESTING

The benchmark Logbook or equivalent self certification

should be completed and signed to demonstrate compliance

with Building Regulations.

A. Electrical Installation

Checks to ensure electrical safety should be carried out

by a competent person.

ALWAYS carry out the preliminary electrical system checks,

i.e. earth continuity, polarity, resistance to earth and short

circuit, using a suitable test meter.

B. Gas Installation

1 The whole of the gas installation, including the meter,

should be inspected and tested for tightness and purged

in accordance with the recommendations of BS. 6891. In

IE refer to I.S. 813:2002.

2 Purge air from the gas installation by loosening the gas

coc k union and purge until gas odour is detected.

3 Retighten the union and test for gas tightness.

WARNING. Whilst effecting the required gas tightness

test and purging air from the gas installation, open all

windows and doors, extinguish naked lights and DO NOT

SMOKE.

INSTALLATION