PROPANE CONVERSION

PAGE 19

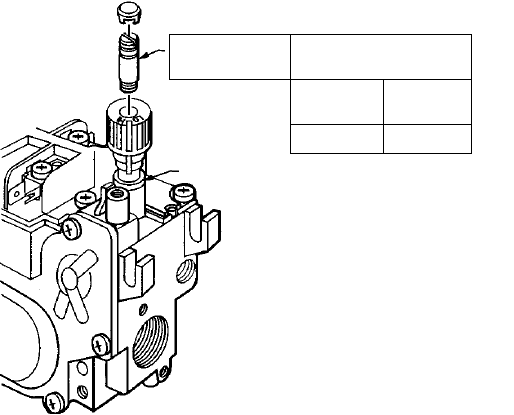

7. High / Low Pressure Regulator Installation Procedure:

a. Remove regulator cap and conversion screw (see fol-

lowing illustration).

b. Install the new conversion screw (Red = Propane LP

gas, Blue = Natural Gas). Ensure that the conversion

screw is finger tight. Install the new regulator cap.

c. Affix conversion label on gas control valve body where

it can easily be seen.

8. Reinstall burner cover, logs, ember wool / ceramic rocks

and glass front.

9. Purging Air from Supply Line:

This should only be done by a qualified and licensed

(where applicable) professional. Check with your local

building official for qualifications required to perform this

procedure.

10. Purge air from the gas line (see #9 above), then connect

propane gas line to the appliance. Connect the fuel line to

the insert inlet (1/2” NPT fitting) using the fitting required.

11. Perform leak Test.

CAUTION

After this procedure is complete with appliance installed

and connected to gas line, recheck the pilot connection

and manifold fittings for leaks, using soapy water or a gas

leak detector.

12. Lighting Procedure-See page 14.

Note: If the gas control knob is turned to the “off” position

after pilot has been lit, the appliance must be allowed to cool

for at least five minutes before pilot flame can be relit.

13. Apply the propane conversion label to the rating label.

The Appliance is ready for use with propane fuel as its only

fuel.

REFERENCE INFORMATION

See pages 4, and 26 of this manual for the following reference

information:

Manifold Gas Pressure

Inlet Gas Pressure

Input Ratings

BURNER FLAME APPEARANCE

A periodic visual check of burner flames should be performed.

The burner flame should appear as indicated on page 20 -

Burner Flame Appearance.

Conversion

Screw

Color Code

Propane Natural

Gas

Red Blue