Installation Instructions (cont'd)

Gas Piping

AWARNING

Make sure the gassuppliedisthe same type listedon the

model rating plate.The inlet gaspressuremust not exceed

10.5in.water column(2.6kPa)for natural gasor 13in,water

column (3.2kPa)for propane(LR) gas.The minimum inlet

gaspressurelistedon the model rating plateisfor the pur-

poseofinputadjustment.

AWARNING

If the gas control valve is subjected to pressuresexceeding ½ [

pound per square inch (3.5kPa), the damage to the gas con-

tro valve could result in a fire or explosion from eak ng gas.

AWARNING

If the main gas line shutoff serving all gas appliances is used, I

also turn "off" the gasat each appliance. Leave all gas appli-

ances shut off until the water heater installation scomp ete.

AWARNING I

Use pipe joint compound or teflon tape marked as being

resistant to the action of petroleum [Propane (L.R)] gases.

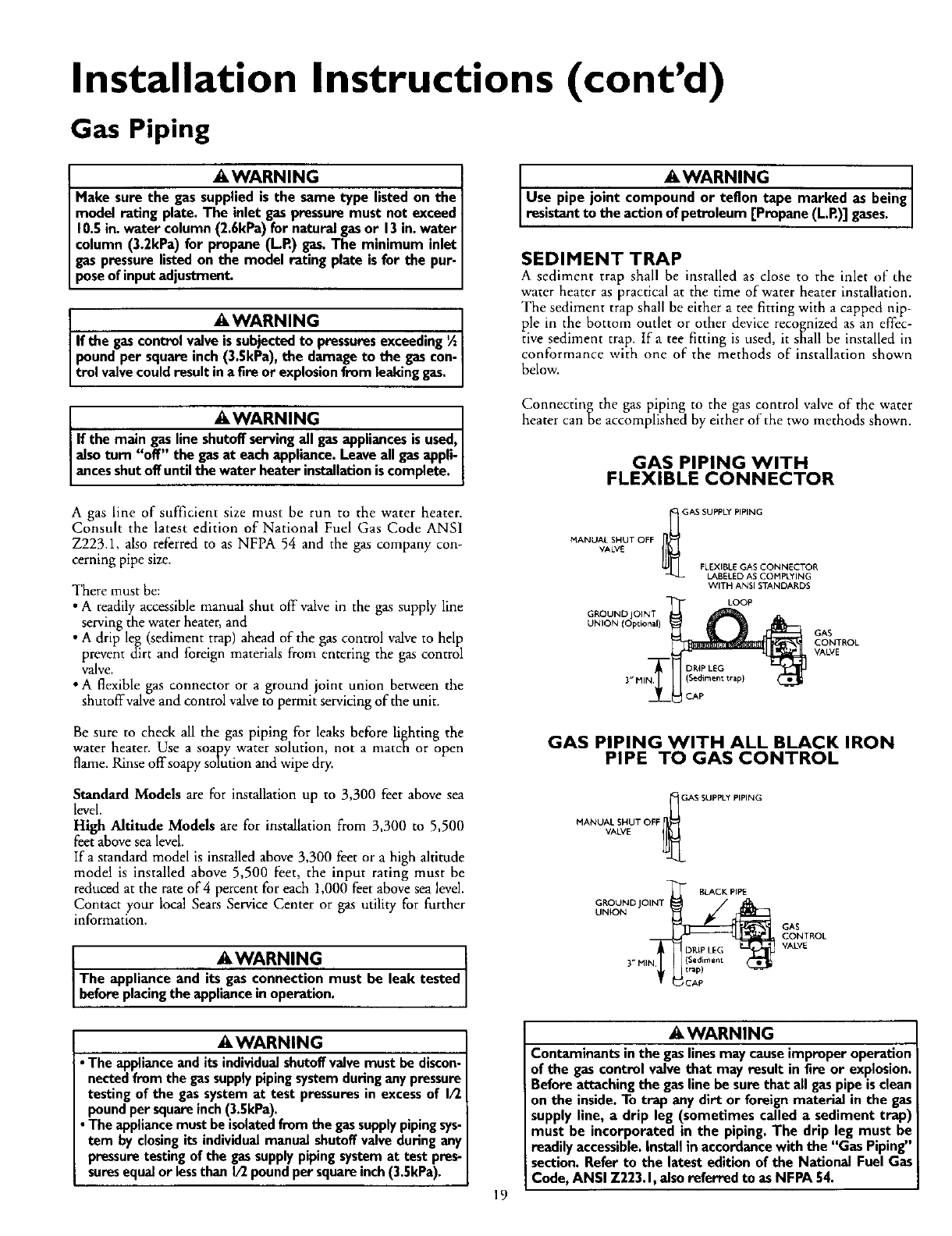

SEDIMENT TRAP

A sediment trap shall be installed as close to the inlet of the

water heater as practical at the time of water heater installation.

The sediment trap shall be either a tee fitting with a capped nip-

pie in the bottom outlet or other device recognized as an effec-

tive sediment trap. Ifa tee fitting is used, it shall be installed in

conformance with one of the methods of installation shown

below.

Connecting the gas piping to the gas control valve of the water

heater can be accomplished by either of the two methods shown.

GAS PIPING WITH

FLEXIBLE CONNECTOR

A gas line of sufficient size must be run to the water heater.

Consult the latest edition of National Fuel Gas Code ANSI

Z223.1, also referred to as NFPA 54 and the gas company con-

cerning pipe size.

There must be:

• A readily accessible manual shut off valve in the gas supply line

serving the water heater, and

• A drip leg (sediment trap) ahead of the gas control valve to help

prevent dirt and foreign materials from entering the gas control

Valve,

• A flexible gas connector or a ground joint union between the

shutoffvalve and control valve to permit servicing of the unit.

Be sure to check all the gas piping for leaks before lighting the

water heater. Use a soapy water solution, not a match or open

flame. Rinse offsoapy solution and wipe dry.

MANUAL SHUT OFF [j_( AS SUPPLY PIPING

VALVE

FLEXIBLE GAS CONNECTOR

LABELED ASCOMPLYING

WITH ANSI STANDARDS

LOOP

GROUND JOIN_

UNION (Optional)

3" MIN.

Standard Models are for installation up to 3,300 feet above sea

level.

High Altitude Models are for installation from 3,300 to 5,500

feet above sea level.

If a standard model is installed above 3,300 feet or a high altitude

model is installed above 5,500 feet, the input rating must be

reduced at the rate of 4 percent for each 1,000 feet above sea level.

Contact your local Sears Service Center or gas utility for further

information.

AWARNING

I The appliance and its gas connection must be leak tested

[ before placing the appllance in operation.

GAS

CONTROL

VALVE

GAS PIPING WITH ALL BLACK IRON

PIPE TO GAS CONTROL

MANUAL SHUT OFF _CAS SUPPLYPIPING

VALVE

GROUND

UNION

BLACK PIPE

(Sediment

trap)

CAP

GAS

CONTROL

VALVE

AWARNING

• The appliance and its individual shutoff valve must be discon-

nected from the gassupplypiping system during any pressure

testing of the gas system at test pressures in excess of I/2

pound per square inch(3.5kPa).

• The appliance must beisolatedfrom the gassupplypipingsys-

tem by closingits individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pres-

suresequal or lessthan I/2 pound per squareinch(3.5kPa).

19

=t WARNING

Contaminants in the gas lines may cause improper operation

of the gas control valve that may result in fire or explosion.

Before attaching the gas line be sure that all gaspipe isclean

on the inside. To trap any dirt or foreign material in the gas

supply line, a drip leg (sometimes called a sediment trap)

must be incorporated in the piping. The drip leg must be

readily accessible. Install in accordance with the "Gas Piping"

section. Refer to the latest edition of the National Fuel Gas

Code, ANSI Z223. I, also referred to asNFPA 54.