13

Gas Supply Connection

The gas supply line connection is made to the left side of

the front-mounted valve. The gas supply line should be

3/8" npt with a 1/2" diameter supply, or the appropriate

size to provide sufficient gas pressure to the valve

regardless of the input setting.

The use of Flexible Gas Appliance Connectors is

acceptable in many areas in the U.S. However, Canadian

methods vary depending on local code.

ALL INSTALLATIONS MUST COMPLY WITH LOCAL

CODE OR IN THE ABSENCE OF LOCAL CODE, MUST

COMPLY WITH THE MOST RECENT EDITION OF THE

NATIONAL FUEL GAS CODE ANSI Z223.1/NFPA 54 OR

CAN-B149.

All codes require a gas shut-off valve (gas cock) and

union, to be installed in the supply line, and in the same

room as the appliance. This allows for the disconnection

of the stove for servicing and maintenance. See fig. 18.

A T-HANDLE GAS COCK IS REQUIRED IN

MASSACHUSETTS TO COMPLY WITH

CODE 248CMR.

Secure all joints tightly using appropriate tools and

sealing compounds. For propane units be sure to use

compounds that are propane resistant. Turn on gas

supply and test for gas leaks using a soapy water solution.

Never use an open flame to check for leaks.

15. Install the new regulator: Be sure the new gasket is

properly positioned and tighten screws securely.

16. Install the identification labels to the stove so that they can

be seen by any person that may be servicing the stove.

Label A: apply to back of stove.

Label B: apply to stove’s rating plate.

Small valve Label: apply to valve.

17. Reassemble the stove, apply gas to the system and

check for leaks using a soapy water solution or

electronic gas detector.

NEVER USE AN OPEN FLAME TO CHECK FOR GAS LEAKS.

18. Correct gas pressure is essential for efficient and safe

operation of this appliance. Use a manometer to

check pressures as specified in the Gas Pressure

section of this manual (page 15).

19. Adjust the Air Shutter. You will need to position the

shutter to provide a gas/air mixture that will achieve

the best flame picture with your particular installa-

tion. Start with the shutter stem at the half-way

position in the slot in the bottom of the stove. See

fig. 12. Pushing the stem back will restrict air, while

pushing it forward will open the shutter and in-

crease air. With some experimentation, you will find

the shutter position that works best for your installa-

tion.

ALWAYS REFER TO THE LIGHTING INSTRUCTIONS ON THE

INSIDE BACK COVER OF THIS MANUAL WHEN LIGHT-

ING YOUR STOVE.

BLOWER NOTE: Install the optional blower before

connecting the gas line in order to ensure adequate

clearance between both.

Valve

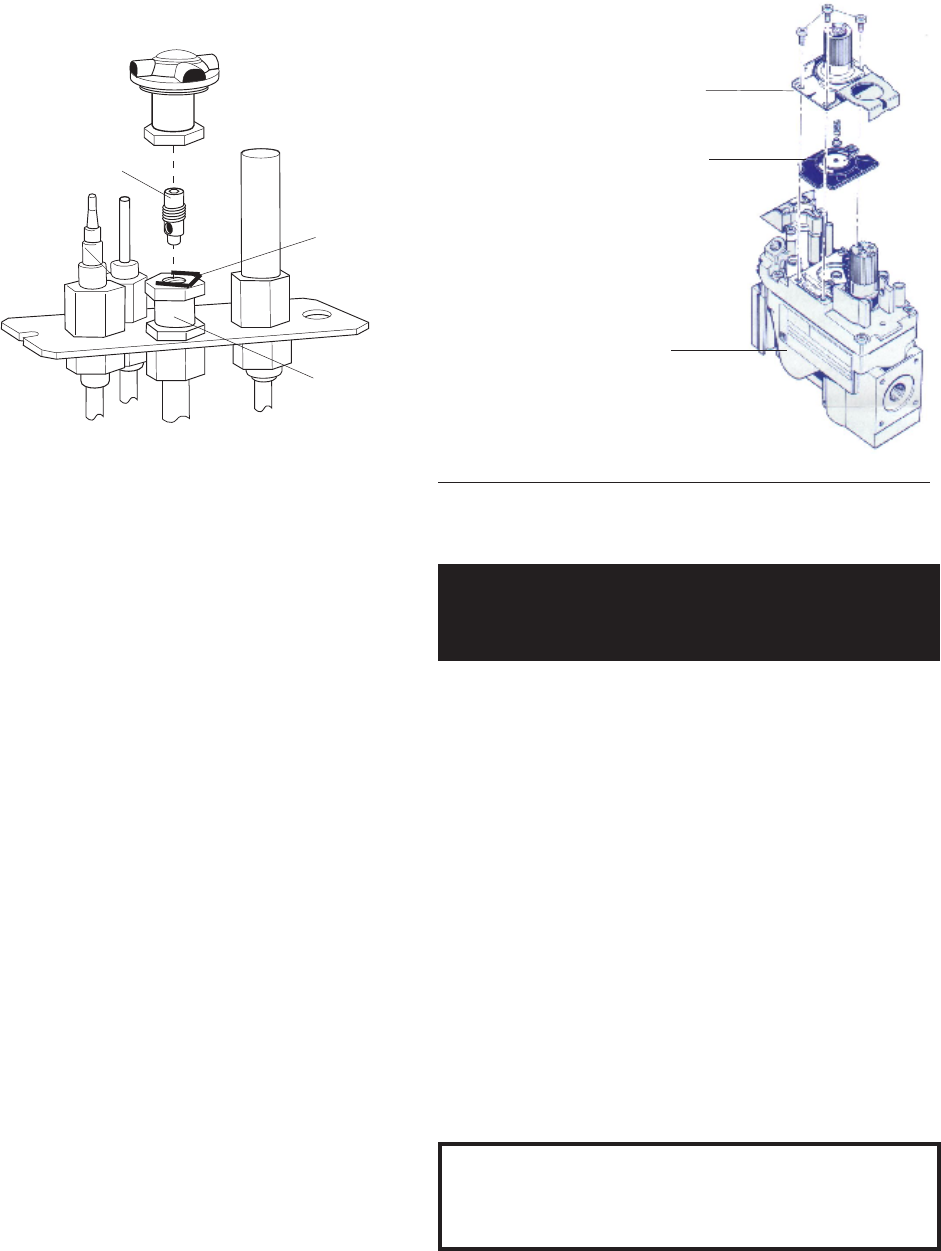

Figure 17 Regulator assembly.

Remove black gasket

from regulator assembly

Regulator Tower

Pilot Head

Orifice

Pilot Base

Figure 16. Pilot orifice removal and replacement.

Retainer

Clip