518676-BIM-E-1210

50 Johnson Controls Unitary Products

Continuous Blower

By setting the room thermostat fan switch to "ON," the supply

air blower will operate continuously.

Intermittent Blower

With the room thermostat fan switch set to "AUTO" and the

system switch set to either the "AUTO" or "HEAT" settings, the

blower is energized whenever a cooling or heating operation is

requested. The blower is energized after any specified delay

associated with the operation.

When energized, the indoor blower has a minimum run time of

30 seconds. Additionally, the indoor blower has a delay of 10

seconds between operations.

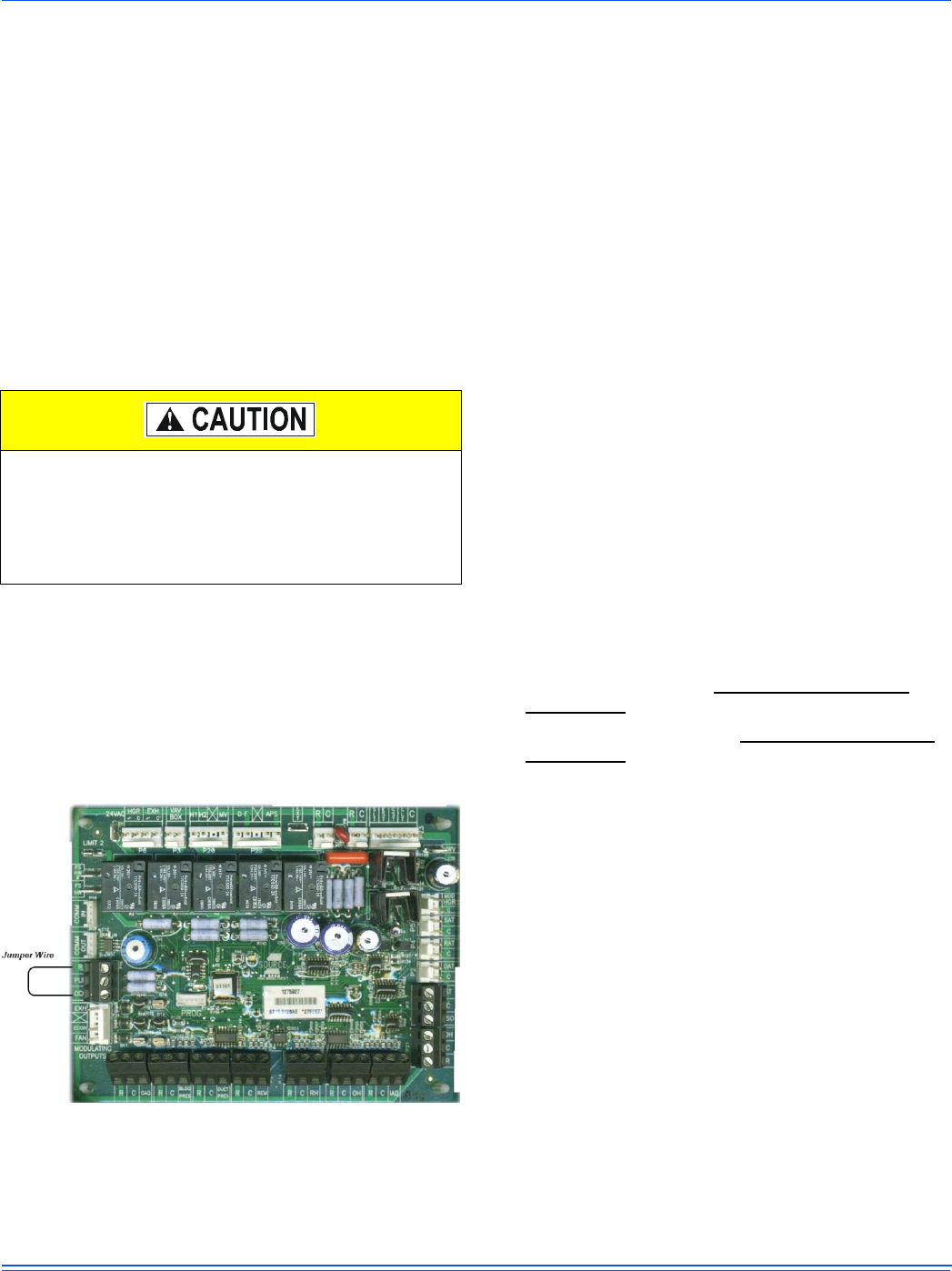

Optional VAV Start-up and Control

For units with VFD and VAV control, the unit must first be put

into the Occupied Mode to start operation. The default setting

for all VAV units is 'Unoccupied', therefore the installer must

add a jumper wire between terminals R - OCC on the VAV add-

on board to put the unit into 'Occupied' Mode. Additionally, the

unit can be switched between Unoccupied/Occupied mode

through network communications with Simplicity™ PC and

other BAS control systems.

Figure 33: Occupied Jumper

Once placed into the Occupied Mode, the speed of the indoor

blower motor is controlled by duct static pressure. The Duct

Static set point (default = 1.5") is the pressure that the VFD

drive will maintain when operating the unit in VAV mode. If the

duct static pressure reaches or exceeds the high-limit set-point

(default = 4.5"), then the supply fan motor will be shutdown.

The Supply Air Temperature (SAT) is controlled by staging

compressors on and off to satisfy the "Operating Cooling

Supply Air Temp Set point". There are 3 set points that

determine the resulting "Operating Cooling Supply Air Temp

Set point".

1. VAV Cooling Supply Air Temp Upper Set point

(default 60° F)

2. VAV Cooling Supply Air Temp Lower Set point

(default 55° F)

3. VAV Supply Air Temp Reset Set point (default 72° F)

When the Return Air Temp (RAT) is above the "VAV Supply Air

Temp Reset Set point" the SAT will be maintained at +/- 5

degrees of the "VAV Cooling Supply Air Temp Lower Set point".

When the Return Air Temp (RAT) is below the "VAV Supply Air

Temp Reset Set point" the SAT will be maintained at +/- 5

degrees of the "VAV Cooling Supply Air Temp Upper Set point".

When the Outdoor air condition is sufficient for free cooling, the

economizer will modulate to control the SAT to +/- 1 degrees of

the operational set point.

The following components are needed to access the control

points in the Simplicity® controller. Installation and operation

guide is located on UPGNET.

1. Computer running Windows software with a standard USB

port.

2. Simplicity® PC Software (http://www.yorkupg.com/

software.asp)

3. Freenet USB adapter driver, (http://www.yorkupg.com/

software.asp)

4. Simplicity® Freenet USB Adapter (S1-03101967000)

5. Freenet service cable (S1-02538682000)

No Outdoor Air Options

When the thermostat calls for the first stage of cooling, the low-

voltage control circuit from “R” to “Y1” and “G” is completed.

The UCB energizes the economizer (if installed and free cooling

is available) or the first available compressor

*

and the

condenser fans. For first stage cooling, compressor #1 is

energized. If compressor #1 is unavailable, compressor #2 is

energized. After completing the specified fan on delay for

cooling, the UCB will energize the blower motor.

When the thermostat calls for the second stage of cooling, the

low-voltage control circuit from “R” to “Y2” is completed. The

control board energizes the first available compressor. If free

cooling is being used for the first stage of cooling, compressor

#1 is energized. If compressor #1 is active for first stage cooling

or the first compressor is locked-out, compressor #2 is

energized. In free-cooling mode, if the call for the second stage

of cooling continues for 20 minutes, compressor #2 is

energized, provided it has not been locked-out.

If the unit is operated with the optional manual bypass

switch in the LINE (BYPASS) position and there are

VAV boxes present in the duct system, then boxes must

be driven to the full-open position using a customer-

supplied power source to prevent over-pressurizing and

possible damage to the ductwork.