518676-BIM-E-1210

36 Johnson Controls Unitary Products

Bas-ready VFD

Factory-installed VFD is also available with 'BAS-Ready'

models. Terminal blocks are provided in the control box (in

place of the VAV control board) for field wiring of a customer-

installed BAS to receive 24 VAC power and to connect to the

following control signals:

• a duct static pressure transducer input signal (0-5 VDC)

• an economizer actuator input signal (2-10 VDC)

• an economizer actuator output signal (2-10 VDC)

• a VFD speed reference output signal (2-10 VDC)

The use of shielded cable is recommended for the above

control wiring connections.

NOTE: Factory-installed VFD is not available with factory-

installed BAS options due to space limitations in the

control box.

A solid-state, lock-out relay (LR) and 100 microfarad, 50 VDC

capacitor must be field-supplied and installed to provide a

means to transmit a potential fault signal back to the BAS

controller. The specific relay part number required will depend

upon the need for either AC-output or DC-output. See price

pages for further details.

Once the appropriate relay and capacitor are obtained, install

the capacitor across LR terminals '3' & '4' and make the

following wiring connections:

• LR '1' to BAS controller

• LR '2' to BAS controller

• LR '3' to UCB 'X'

• LR '4' to UCB 'C'

'VFD-ready' For Customer-installation

Units configured as 'VFD-ready' provide provisions for a

customer-installed drive. The physical dimensions of VFDs can

vary greatly among manufacturers, horsepower ratings and

voltage requirements. Keep in mind that drive manufacturers

also require various minimum clearances to allow for adequate

internal cooling of the drive during operation.

The unit comes with a mounting bracket installed in the Blower

Access compartment which may accommodate other vendor's

drives depending on their size. In order to utilize the unit's

mounting bracket, the maximum recommended drive

dimensions are limited to approximately 9" H x 5" W x 7.5" D.

If the drive will not fit in the allotted space, then it will need to be

mounted elsewhere; either within the building on a

perpendicular wall which is not subjected to excessive

temperature, vibration, humidity, dust, corrosive gas, explosive

gas, etc., or within an appropriate enclosure rated for outside

installation to safeguard against moisture, dust and excessive

heat.

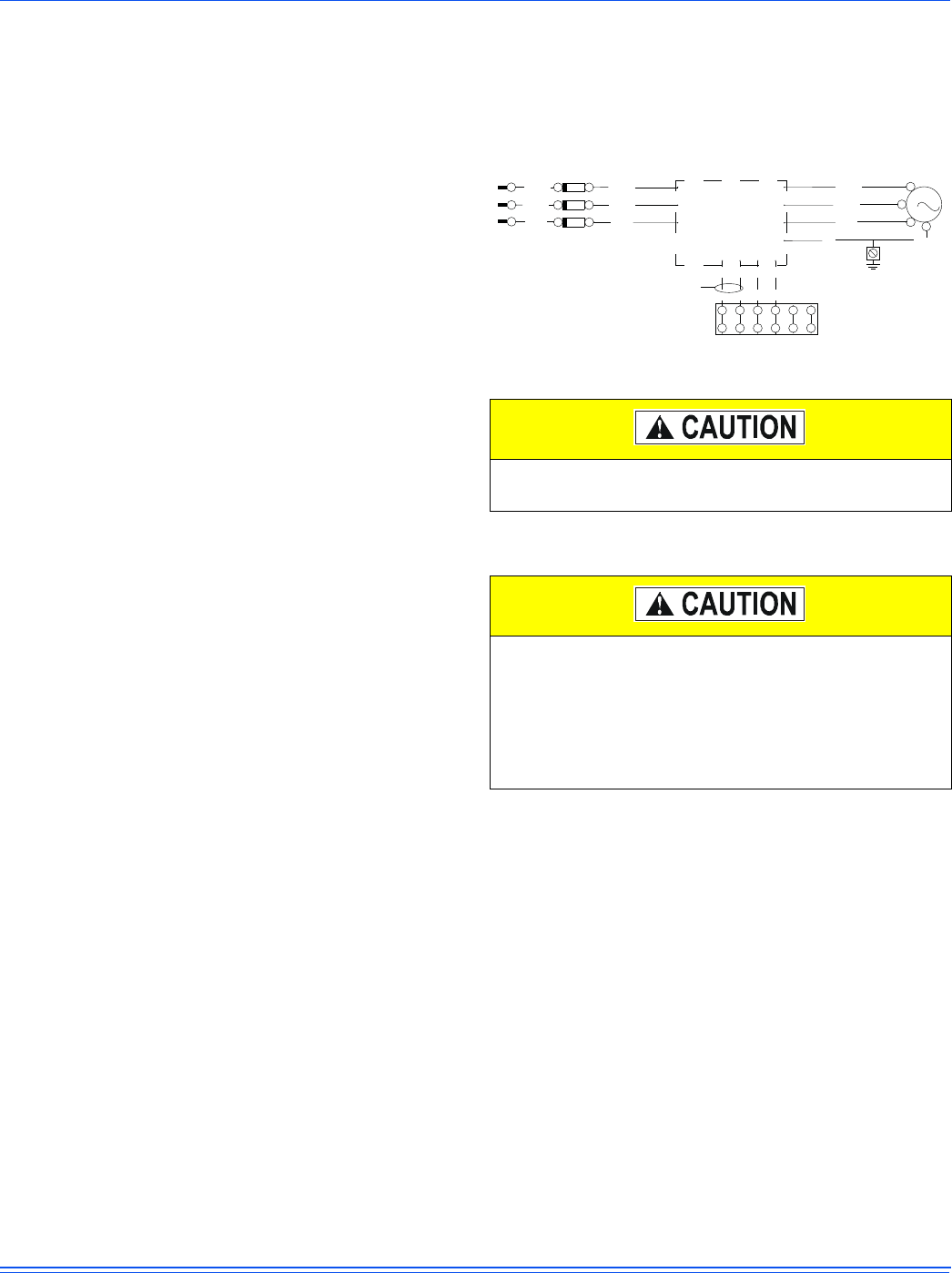

The power leads to the drive (L1, L2, L3) and from the motor

(T1, T2, T3) have been temporarily spliced together with wire

nuts. After removing the wire nuts, connect the wires to the

field-installed VFD per the VFD wiring diagram (See Figure 27).

The VFD should also be grounded per the manufacturer's

specifications.

Figure 27: Simplified VFD Wiring

A terminal block located in the control box is provided for field

connection of the VFD speed reference signal (2-10 VDC) and

to the normally-open, run-permit auxiliary contact. The use of

shielded cable is recommended for the above control wiring

connections. For VFD-ready units also equipped with gas/

electric heat, a terminal block located in the unit's control box

and connected to the VAV board's "VAV BOX" terminal, must

be field wired to the building's VAV boxes to ensure fully open

dampers during heating operation.

Optional Hot Gas Bypass (HGBP)

To allow for low cooling load operation, a direct-acting,

pressure-modulating bypass control valve installed on the

system #1 discharge line is used to divert high temperature,

high pressure refrigerant around the TXV in order to maintain a

desired minimum evaporator pressure.

The opening pressure of the bypass valve is adjustable

between 95 and 115 psig with a factory-setting of 105 psig.

Do not connect AC power to the T1, T2, T3 drive

terminals to prevent damage to the VFD.

The fuses (FU3, FU4, FU5) supplied with the unit are

sized according to the electrical load of the blower

motor, but may not provide adequate protection to the

customer-installed drive, depending upon its

specifications. Once a drive has been selected and

installed, refer to the drive manufacturer's

recommendations for proper fuse sizing.

ELEMENTARY DIAGRAM

VFD

TB8 (IN CONTROL BOX)

RUN PERMIT

(DIGITAL)

SPEED REF

(ANALOG)

(2-10 VDC)

GND

GRN

GND

GRN

GND

1 DMTR

118 / BK

119 / BR

120 / Y

3

M

(T1)

(T2)

(T3)

( )

(L1)

(L3)

(L2)

722 / BK

725 / BR

728 / Y

720 / PR

723 / BR

726 / O

TB1

FU3

FU5

FU4

12345

6

L3

L2

L1

T1

T2

T3