518676-BIM-E-1210

32 Johnson Controls Unitary Products

Gas Connection

The gas supply line can be routed within the space and roof curb,

exiting through the unit’s basepan. Refer to Figures 8 and 9 for

the gas piping inlet location. Typical supply piping arrangements

are shown in Figures 25 and 26. All pipe nipples, fittings, and the

gas cock are field supplied or may be purchased in UP accessory

kit #1GP0405.

Gas piping recommendations:

1. A drip leg and a ground joint union must be installed in the

gas piping.

2. Where required by local codes, a manual shut-off valve

must be installed outside of the unit.

3. Use wrought iron or steel pipe for all gas lines. Pipe dope

should be applied sparingly to male threads only.

4. All piping should be cleaned of dirt and scale by

hammering on the outside of the pipe and blowing out

loose particles. Before initial start-up, be sure that all gas

lines external to the unit have been purged of air.

5. The gas supply should be a separate line and installed in

accordance with all safety codes as prescribed under

“Limitations”.

6. A 1/8-inch NPT plugged tapping, accessible for test gage

connection, must be installed immediately upstream of the

gas supply connection to the unit.

7. After the gas connections have been completed, open the

main shut-off valve admitting normal gas pressure to the

mains. Check all joints for leaks with soap solution or other

material suitable for the purpose. NEVER USE A FLAME.

LP Units, Tanks And Piping

All gas heat units are shipped from the factory equipped for

natural gas use only. The unit may be converted in the field for

use with LP gas with accessory kit model number 1NP0442.

All LP gas equipment must conform to the safety standards of

the National Fire Protection Association.

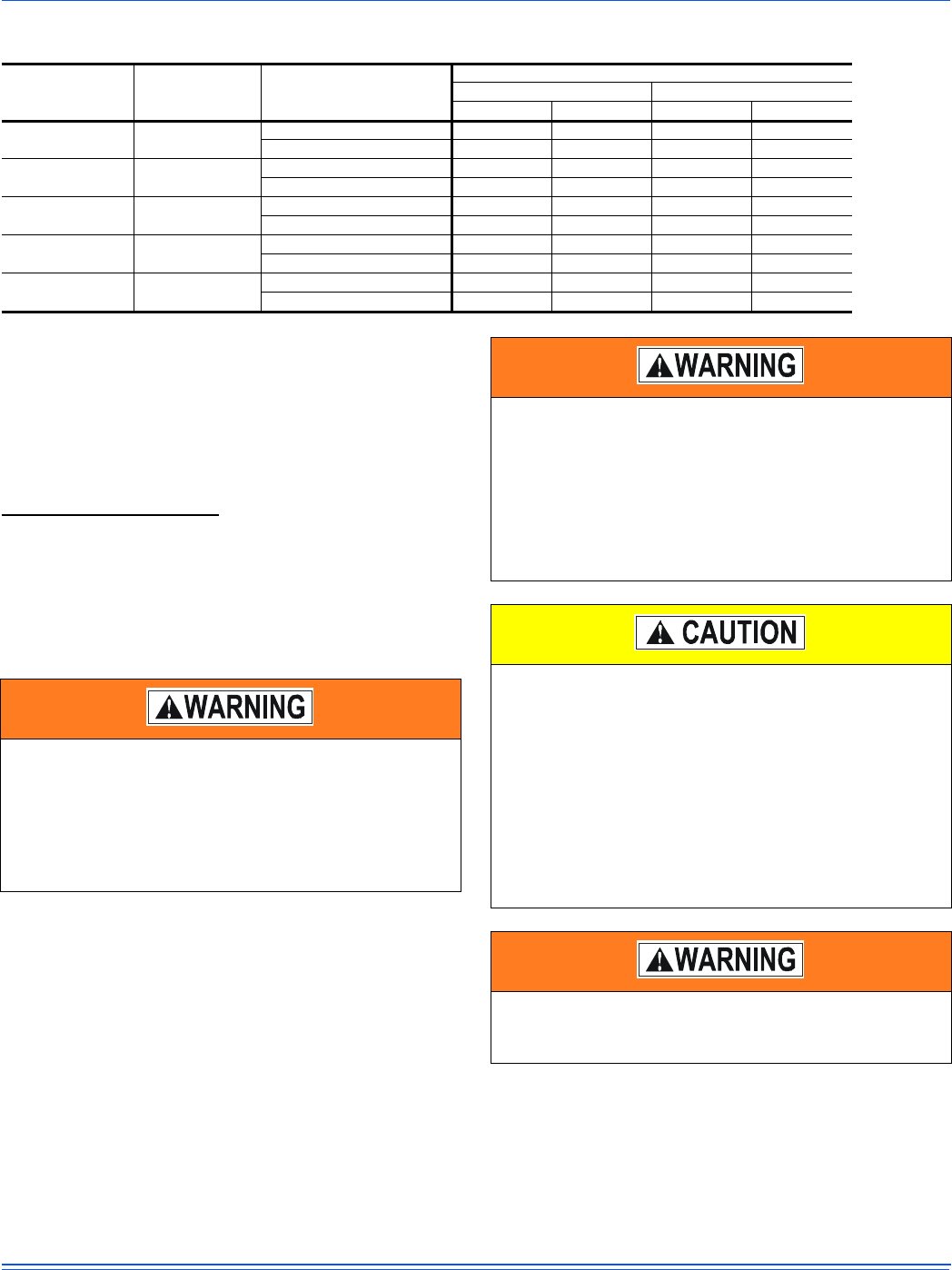

Table 12: Gas Heat Minimum Supply Air

Size

(Tons)

Model Heat Size

Supply Air (CFM)

Cooling Heating

Min Max Min Max

-06

(6.5)

ZS

12 1950 3250 1950 3250

18 1950 3250 1950 3250

-07

(7.5)

ZS

12 2250 3750 2250 3750

18 2250 3750 2250 3750

-08

(8.5)

ZS

12 2550 4250 2550 4250

18 2550 4250 2550 4250

-10

(10)

ZS

18 3000 5000 3000 5000

24 3000 5000 3000 5000

-12

(12.5)

ZS

18 3750 6250 3750 6250

24 3750 6250 3750 6250

Natural gas may contain some propane. Propane is an

excellent solvent and will quickly dissolve white lead and

most standard commercial compounds. A special pipe

dope must be used when assembling wrought iron or

steel pipe. Shellac based compounds such as Gaskolac

or Stalastic, and compounds such as Rectorseal #5,

Clydes’s or John Crane may be used.

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warning exactly could result

in serious injury, death or property damage.

Never test for gas leaks with an open flame. use a

commercially available soap solution made specifically

for the detection of leaks to check all connections. A fire

or explosion may result causing property damage,

personal injury or loss of life.

The furnace and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing at pressures in excess of 1/2 PSIG.

Pressures greater than 1/2 PSIG will cause gas valve

damage resulting in a hazardous condition. If it is

subjected to a pressure greater than 1/2 PSIG, the gas

valve must be replaced.

The furnace must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 PSIG.

Threaded joints should be coated with a sealing

compound that is resistant to the action of liquefied

petroleum gases. Do not use Teflon tape.