VR8104, VR8204 AND VR8304 INTERMITTENT PILOT COMBINATION GAS CONTROLS

7 69-1225—4

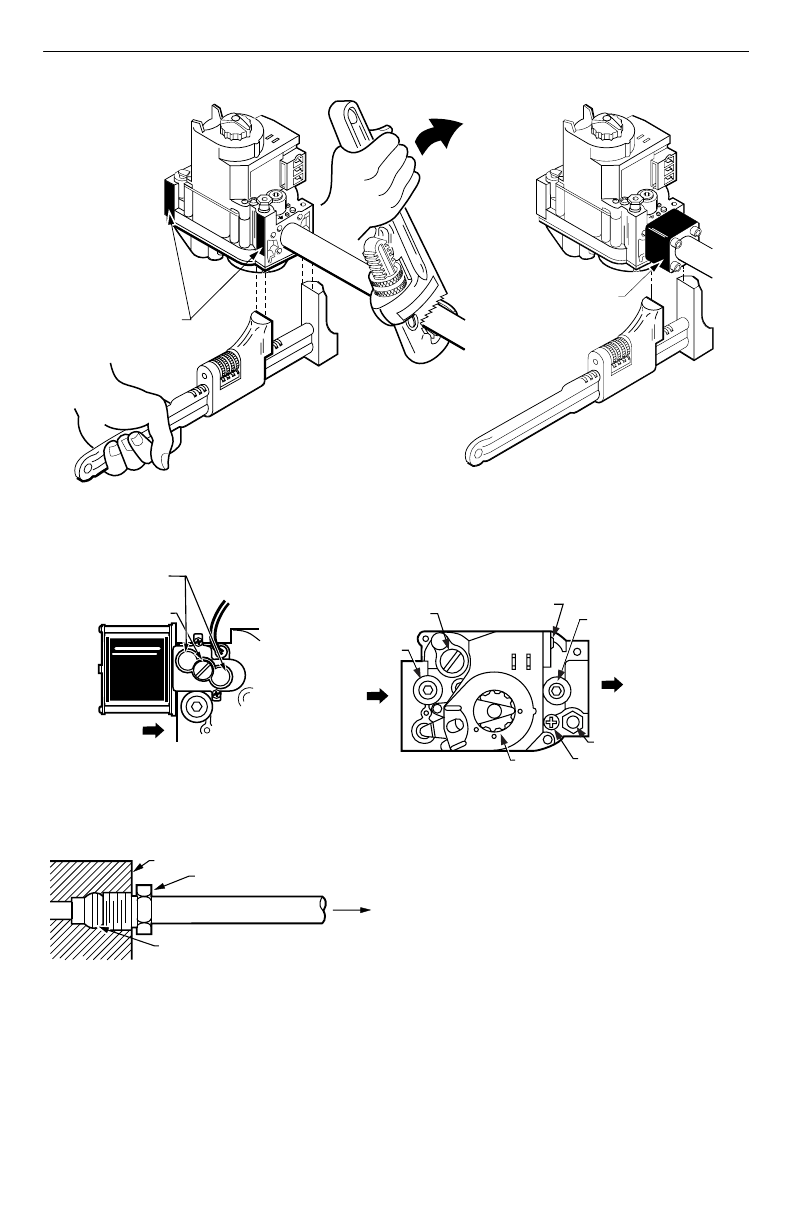

Fig. 5. Proper use of wrench on gas control with and without flanges.

Fig. 6. Top view of gas control.

Fig. 7. Always use new compression fitting.

Wiring

Follow the wiring instructions furnished by the appliance

manufacturer, if available, or use the general instructions

provided below. When these instructions differ from the

appliance manufacturer, follow the appliance

manufacturer instructions.

All wiring must comply with applicable electrical codes

and ordinances.

Disconnect power supply before making wiring

connections to prevent electrical shock or equipment

damage.

1.

Check the power supply rating on the gas control

and make sure it matches the available supply.

Install a transformer, thermostat and other controls

as required.

2.

Connect control circuit to the gas control terminals.

See Fig. 8.

APPLY WRENCH

FROM TOP OR

BOTTOM OF GAS

CONTROL TO

EITHER SHADED AREA

WHEN FLANGE IS NOT USED

APPLY WRENCH

TO FLANGE ONLY

WHEN FLANGE IS USED

M3079

HI-LO

ADJUSTMENT SCREWS

(UNDER CAP)

REGULATOR

VENT COVER

INLET

INLET

OUTLET

M10968A

HI

LO

OUTLET

PRESSURE

TAP

WIRING

TERMINALS (3)

INLET

PRESSURE TAP

PRESSURE REGULATOR

ADJUSTMENT

(UNDER CAP SCREW)

PILOT OUTLET

PILOT ADJUSTMENT

(UNDER CAP SCREW)

GAS

CONTROL

KNOB

TWO-STAGE

PRESSURE

REGULATOR

MODEL

GAS CONTROL

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT.

FITTING BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED.

TO PILOT

BURNER

M3076A