VR8104, VR8204 AND VR8304 INTERMITTENT PILOT COMBINATION GAS CONTROLS

3 69-1225—4

SPECIFICATIONS

Body Pattern:

Straight through; see Table 1 for inlet and

outlet size.

Electrical Ratings:

Voltage and Frequency: 24 Vac, 60 Hz.

Current Draw: 0.5A with both operators energized.

Capacity:

See Table 1.

Conversion:

Use conversion factors in Table 2 to con-

vert capacities for other gases.

Regulation Range:

See Table 1.

Natural-LP Gas Conversion Kits:

See Table 5.

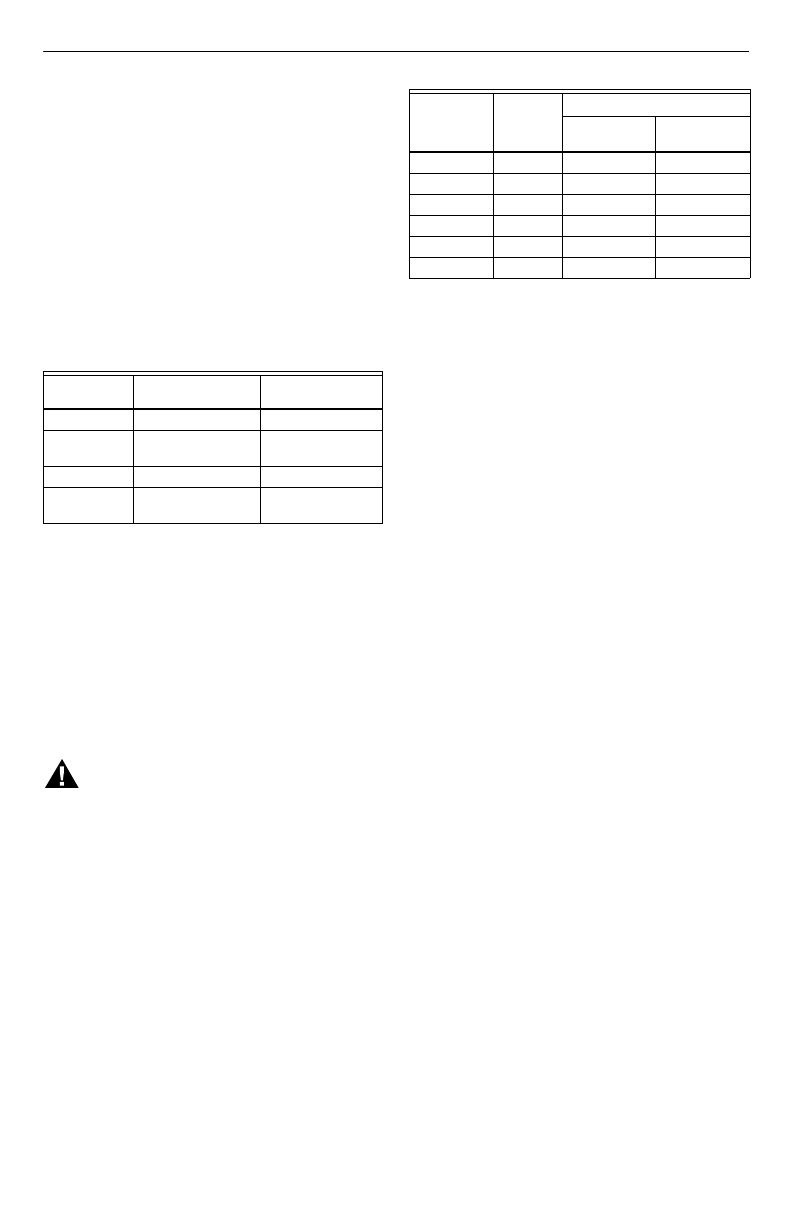

Table 5. Natural-LP Gas Conversion Kits.

Pipe Adapters:

Angle and straight adapters available for 3/8-, 1/2- and

3/4-in. pipe. See Table 6. Flange kits include one

flange with attached O-ring, four mounting screws, a

9/64 in. hex wrench and instructions.

Approvals:

American Gas Association Design Certificate: L2025006.

Canadian Gas Association Design Certificate: L2025006.

Australian Gas Association Design Certificate: 4214.

Approved for Delta C applications.

European Community (CE) Certificate: Pending.

PLANNING THE INSTALLATION

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury,

or death.

Follow these warnings exactly:

1. Plan the installation as outlined below.

2. Plan for frequent maintenance as described in

the Maintenance section.

Table 6. Flange Adapter Part Numbers.

a

Flange kits include one flange, one O-ring and four

mounting screws.

b

Do not use flanges on control models with 3/4 in. inlet

and 3/4 in. outlet. On models with 1/2 in. inlet and

3/4 in. outlet, use flanges only on the 1/2 in. inlet side.

Heavy demands are made on the controls when

intermittent pilot systems are used on central heating

equipment in barns, greenhouses, and commercial

properties and on heating appliances such as

commercial cookers, agricultural equipment, industrial

heating equipment and pool heaters.

Special steps may be required to prevent nuisance

shutdowns and control failure due to frequent cycling,

severe environmental conditions related to moisture,

corrosive chemicals, dust or excessive heat. These

applications require Honeywell Home and Building

Control Engineering review; contact your Honeywell

Sales Representative for assistance.

Review the following conditions that can apply to your

specific installation and follow the precautions

suggested.

Frequent Cycling

This control is designed for use on appliances that

typically cycle three to four times an hour only during the

heating season. In year-around applications with greater

cycling rates, the control can wear out more quickly.

Perform a monthly checkout.

Water or Steam Cleaning

If a control gets wet, replace it. If the appliance is likely to

be cleaned with water or steam, protect (cover) the

control and wiring from water or steam flow. Mount the

control high enough above the bottom of the cabinet so it

does not get wet during normal cleaning procedures.

High Humidity or Dripping Water

Dripping water can cause the control to fail. Never install

an appliance where water can drip on the control. In

addition, high ambient humidity can cause the control to

corrode and fail. If the appliance is in a humid

atmosphere, make sure air circulation around the control

is adequate to prevent condensation. Also, regularly

check out the system.

Model No.

Suffix Letter

Kit to Convert

Natural Gas to LP

Kit to Convert LP

to Natural Gas

H, K, M 393691 394588

P Not field

convertible.

Not field

convertible.

Q 396021 396025

R Not required,

convertible valve.

Not required,

convertible valve.

Inlet/Outlet

Pipe Size

(in. NPT)

Flange

Type

Part Number

a,b

Without Hex

Wrench

With Hex

Wrench

3/8 Straight 393690-1 393690-11

3/8 Elbow 393690-2 393690-12

1/2 Straight 393690-6 393690-16

1/2 Elbow 393690-3 393690-13

3/4 Straight 393690-4 393690-14

3/4 Elbow 393690-5 393690-15