FM USER INSTRUCTIONS ENGLISH 71576526 - 03/07

Page 19 of 32 flowserve.com

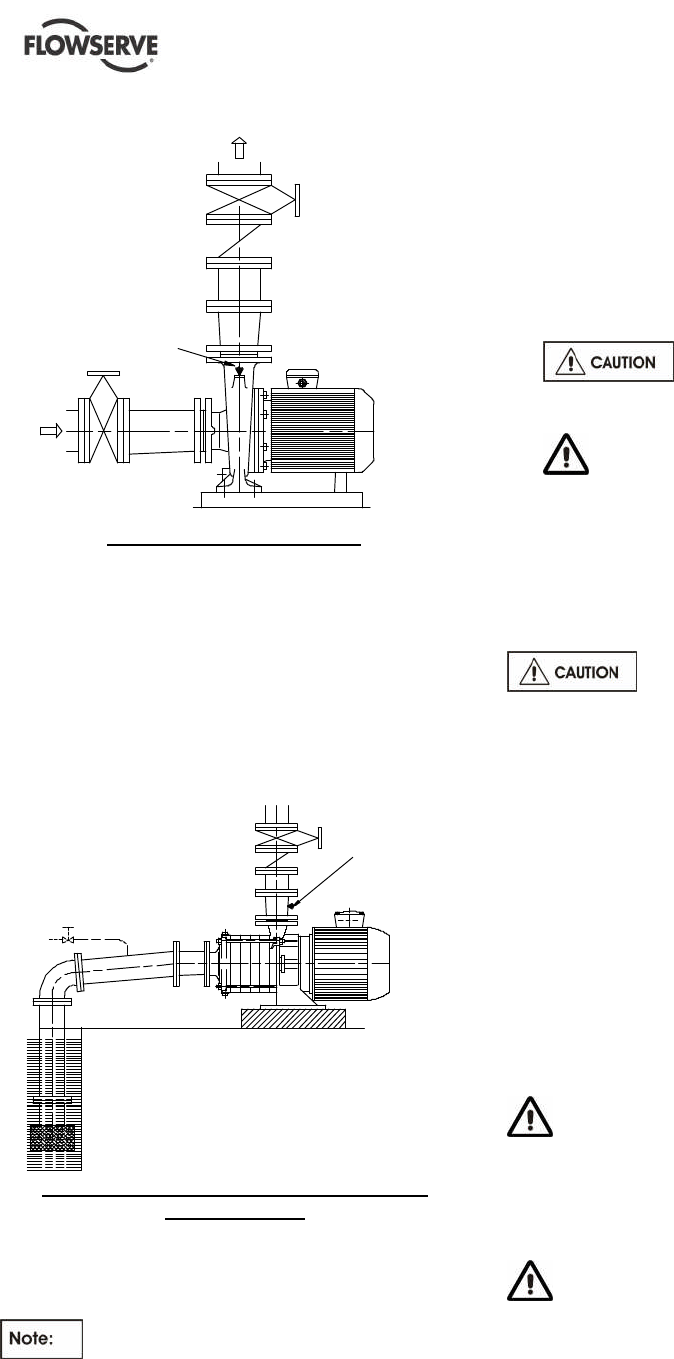

Air escape

Priming of a flooded pump

5.3.2 Priming of a sump suction pump

* With foot valve:

a) Fill suction pipe and casing with liquid from an

independent source (pressure 1 to 2 bars or 15

to 30 psi).

b) Let air escape by removing the plugs located on

the piping.

c) When the pump is totally free of air bubbles,

replace the plugs.

Air escape

External source

Priming of a sump suction configuration

with foot valve

* Without foot valve:

Priming may be accomplished by means of venting

system.

Foot valves are not recommended when

the pumped liquid has suspended solid particles.

They may lodge between foot valve seat and

shutter.

5.4 Starting the pump

5.4.1 Bring controls and preparation before the

first starting and after each service call

Necessarily:

a) Check the tightening of the different plugs.

b) Check that the gland lightly tightens the packing

rings.

c) Risk of seal ring overheating.

d) Check the direction of rotation of the motor.

Refer to the rotation arrow of the pump.

e) DO NOT FORGET TO REMOUNT THE

SHIELD GRID ON THE MOTOR STOOL

f) Open all inlet valves (if existing).

g) Close the outlet valve and the bypass valve.

h) Ensure inlet pipe and pump casing are

completely full of liquid.

5.4.2 First pump start-up

Suction valves must be fully open

when pump is running. Never run the pump dry, it

will cause damage.

a) Start motor and check outlet pressure.

b) If pressure is satisfactory, slowly OPEN the

outlet valve.

c) Do not run the pump with the outlet valve closed

for a period longer than 30 seconds.

d) If NO pressure, or LOW pressure, STOP the

pump. Refer to fault finding chart for fault

diagnosis.

The pump should run smoothly and without

vibration.

The pump must never run at a capacity less than

10 % of the best efficiency point.

Never remove a plug when the pump is

running.

5.5 Running the pump

5.5.1 Venting the pump

Vent the pump to enable all trapped air to

escape taking due care with hot or hazardous

liquids.

Under normal operating conditions, after the pump

has been fully primed and vented, it should be

unnecessary to re-vent the pump.