FM USER INSTRUCTIONS ENGLISH 71576526 - 03/07

Page 17 of 32 flowserve.com

The non-return valve will be set in the discharge

pipe to protect the pump from any excessive

pressure surge and from reverse rotation.

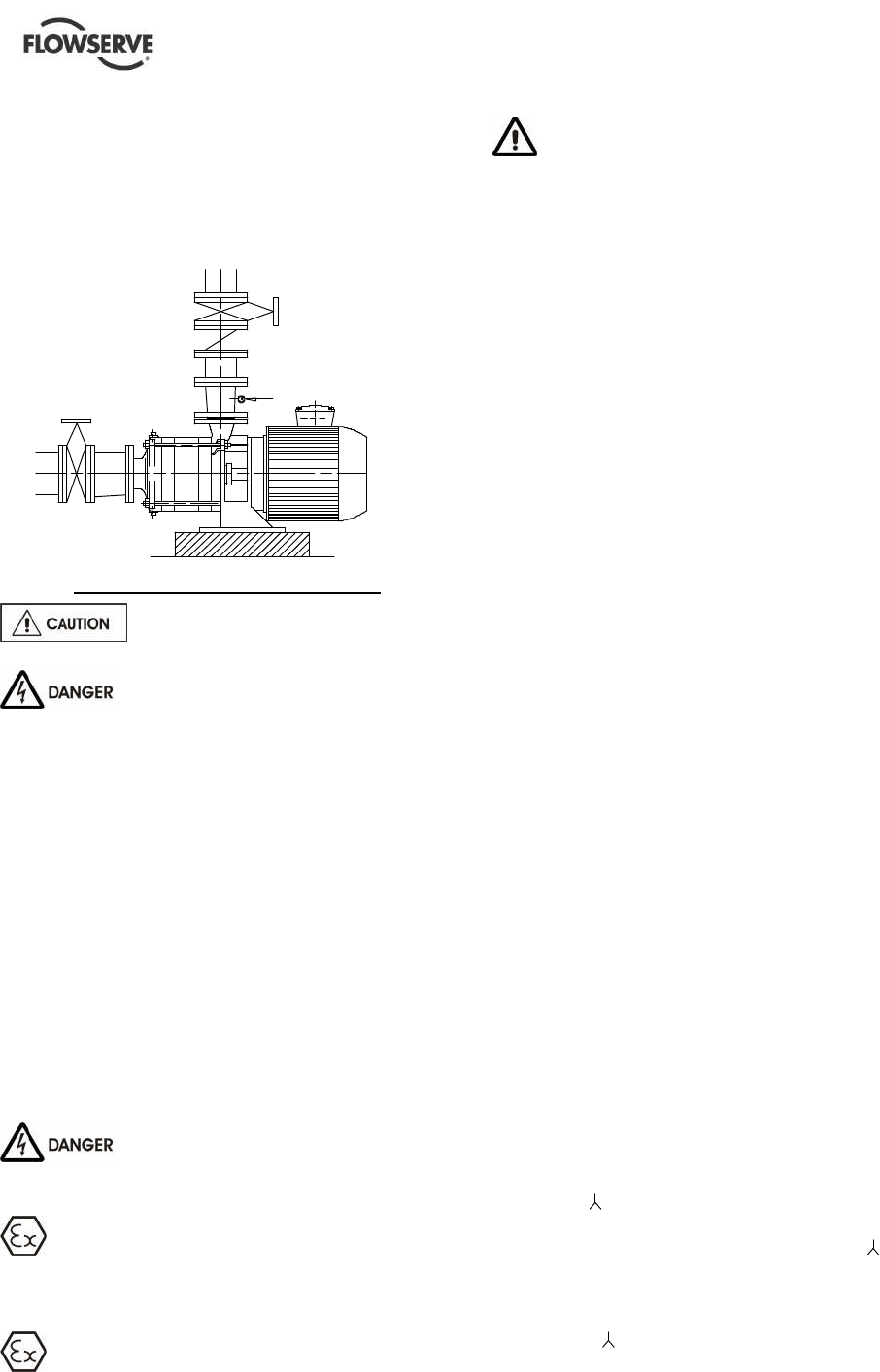

If necessary, a control manometer (pressure gauge)

can be connected on the piping.

Control manometer

Setting of the control manometer

Do not tighten flanges before the final

check (see § 4.3.4).

Never connect the electric motor

before the setting has been completely finished.

4.3.4 Final checks

a) Check the tightening of anchor bolts. Tighten

them if necessary.

b) Check that protective covers on suction and

discharge flanges are removed.

c) Check that holes of piping flanges are parallel

and correspond to those of the pump.

d) Tighten suction and discharge flanges.

e) If it is planned, connect piping(hydraulic,

pneumatic, sealing system).

f) Control seal and the working of auxiliary piping.

4.4 Electrical connections

4.4.1 Safety conditions about electrical

connections

Electric connections must be carried

out by a qualified electrician, following the local rules

and regulations in force.

It is important to be aware of the EUROPEAN

DIRECTIVE on potentially explosive areas where

compliance with IEC60079-14 is an additional

requirement for making electrical connections.

Avoid mechanical, hydraulic or electrical

overload by using motor overload trips or a power

monitor and make routine vibration monitoring.

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site. Attention

must be paid to ensure that the techniques used during

wiring/installation do not increase electromagnetic

emissions or decrease the electromagnetic immunity of

the equipment, wiring or any connected devices. If in

doubt, contact Flowserve for advice.

Before connecting the electric power supply, if the

device has been kept in a damp atmosphere, have

the insulation resistance of the electric motor

checked.

This resistance should have a value of not less than

5 000 ohms for each volt of the supply.

Carry out the ground connections according to the

current local regulations.

The motor must be protected. The protection must

therefore be ensured by a magneto thermal breaker

located between the section switch and the motor.

This breaker can be connected to fuses.

Use a breaker sized and provisionally adjusted to

the current specified on the description plate.

It is recommended to provide the power supply of

the electric motor with a monitoring device allowing

the machine to be shut down safely.

A device to provide emergency stopping shall be

fitted.

4.4.2 Electrical supply

Make sure that the voltage of the electrical supply

line is correct for that specified on the motor

description plate.

Make sure that the supply wires have sufficient load

capacity for the correct running of the installation.

4.4.3 Wiring Instructions

The motors are closed type IP 55 class E - 50 Hz

230/ 400 V up to 3.7 kW - 50 H:

The motors can be directly supplied with 230 or

400 V according to the coupling (starting with

230 V is possible but not advised)

400 V from 5.5 kW -50 Hz:

The motors can be directly supplied with 400 V

(starting with 400 V is possible but not

advised). Astatoric start is advised.