FM USER INSTRUCTIONS ENGLISH 71576526 - 03/07

Page 18 of 32 flowserve.com

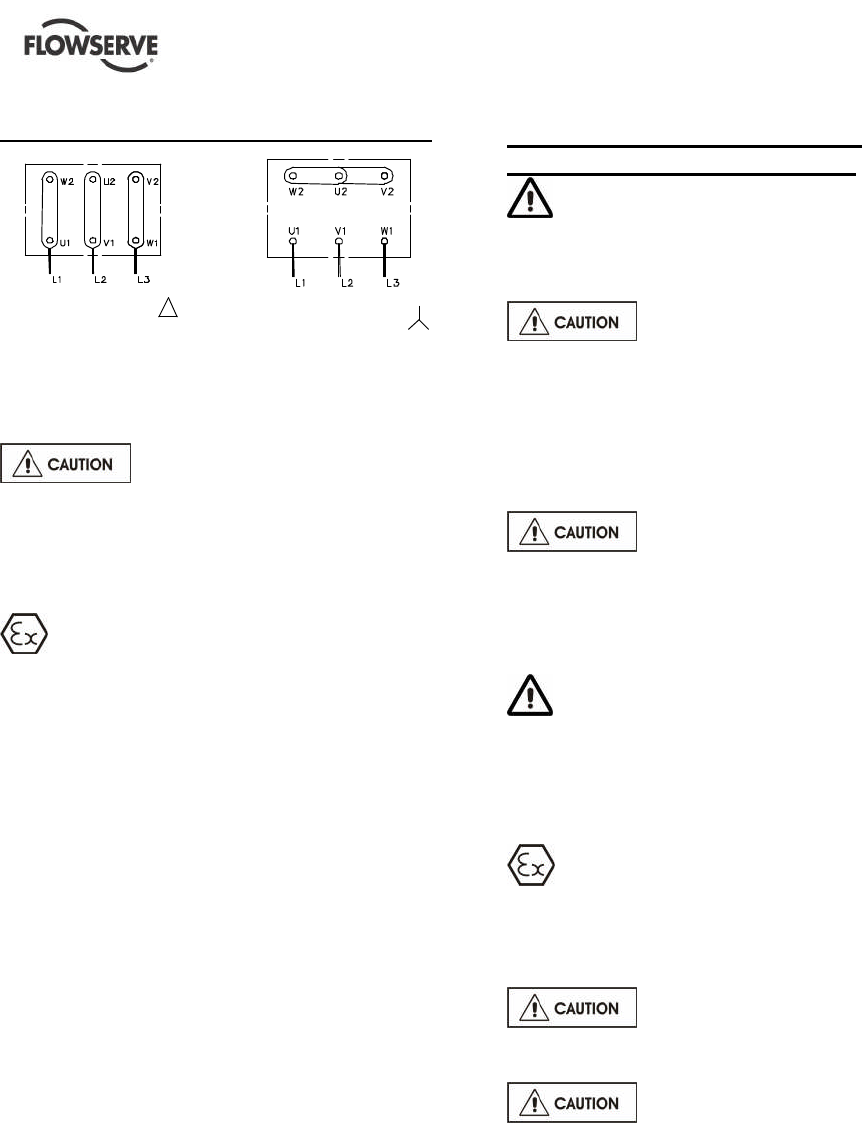

Connection wiring diagram for three phase motors:

Delta connection

Wire up the motor terminals according to the voltage

supply, in accordance with the description plate fixed

on the motor and with the connection wiring diagram

mentioned on the terminal box as opposite.

To avoid any risk of jamming, the

direction of rotation will be checked after priming of

the pump (§ 5.3.1, 5.3.2) and before the first start (§

5.4.2).

4.5 Protection systems

The following protection systems are

recommended particularly if the pump is installed in

a potentially explosive area or is handling a

hazardous liquid. If in doubt consult Flowserve. If

there is any possibility of the system allowing the

pump to run against a closed valve or below

minimum continuous safe flow a protection device

should be installed to ensure the temperature of the

liquid does not rise to an unsafe level.

If there are any circumstances in which the system

can allow the pump to run dry, or start up empty, a

power monitor should be fitted to stop the pump or

prevent it from being started. This is particularly

relevant if the pump is handling a flammable liquid.

If leakage of product from the pump or its associated

sealing system can cause a hazard it is

recommended that an appropriate leakage detection

system is installed.

To prevent excessive surface temperatures at

bearings it is recommended that temperature or

vibration monitoring are carried out. See sections

5.5.4 and 5.5.5.

If a defect of cooling can lead to temperature higher

than those acceptable a system of cooling

surveillance must be installed.

Except when explicitly required by the customer in

the specifications, when a possibility of reverse

rotation exists the customer must install a reverse

rotation protection device.

The customer must install all equipment required to

avoid water hammer.

5 COMMISSIONING START-UP,

OPERATION AND SHUTDOWN

These operations must only be carried out

by qualified personnel.

5.1 Direction of rotation

Starting or operating pumps with the

wrong direction of rotation can be harmful to the

pumps. Ensure that the pump rotation is the same

as the arrow on the pump casing.

It is preferable to check the direction of rotation

before installing the coupling. If not, the pump must

be filled in with the liquid before start-up.

If maintenance work has been carried

out to the site's electricity supply, the direction of

rotation should be re-checked as above in case the

supply phasing has been altered.

5.2 Guarding

Guarding is supplied fitted to the pump set.

If this has been removed or disturbed ensure that all

the protective guards around the pump coupling and

exposed parts of the shaft are securely fixed.

5.3 Priming and auxiliary supplies

Where there is any risk of the pump being run

against a closed valve generating high liquid and

casing external surface temperatures it is

recommended that users fit an external surface

temperature protection device.

Ensure all electrical, hydraulic,

pneumatic, sealant and lubrication systems (as

applicable) are connected and operational.

Ensure the inlet pipe and pump

casing are completely full of liquid before starting

continuous duty operation.

These operations must be carried out by personnel

with approved qualifications.

5.3.1 Priming of a flooded pump

a) Close the discharge valve, fill the pump by

opening the suction valve. Let air escape by

removing the plug located on the piping.

b) The discharge pipe is headed and there is a by-

pass valve on the check valve, open slightly the

discharge valve and the by-pass of the check

valve.

c) When the pump is totally free of air bubbles,

replace the plugs.

Star connection