5

FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755 • www.flintandwalling.com

Mount pump in correct position or pump failure will result.

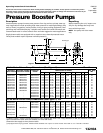

Figure 2 - No Air Pockets in Inlet Pipe

Figure 3 - Inlet Pipe Must Not Leak

Figure 5

IMPORTANT: Clean all filters and strainers on a regular schedule.

IL0418

IL0419

IL0420

No Sags

Sags Allow Air Pockets

No Air Leaks In

Inlet Pipe

Pipe Joint Compound

Will Damage Plastic

If Air Flows

Water

Won’t

If Air Pockets Form,

Water Won’t Flow

Use Teflon Tape

IL0315

Correct

Incorrect

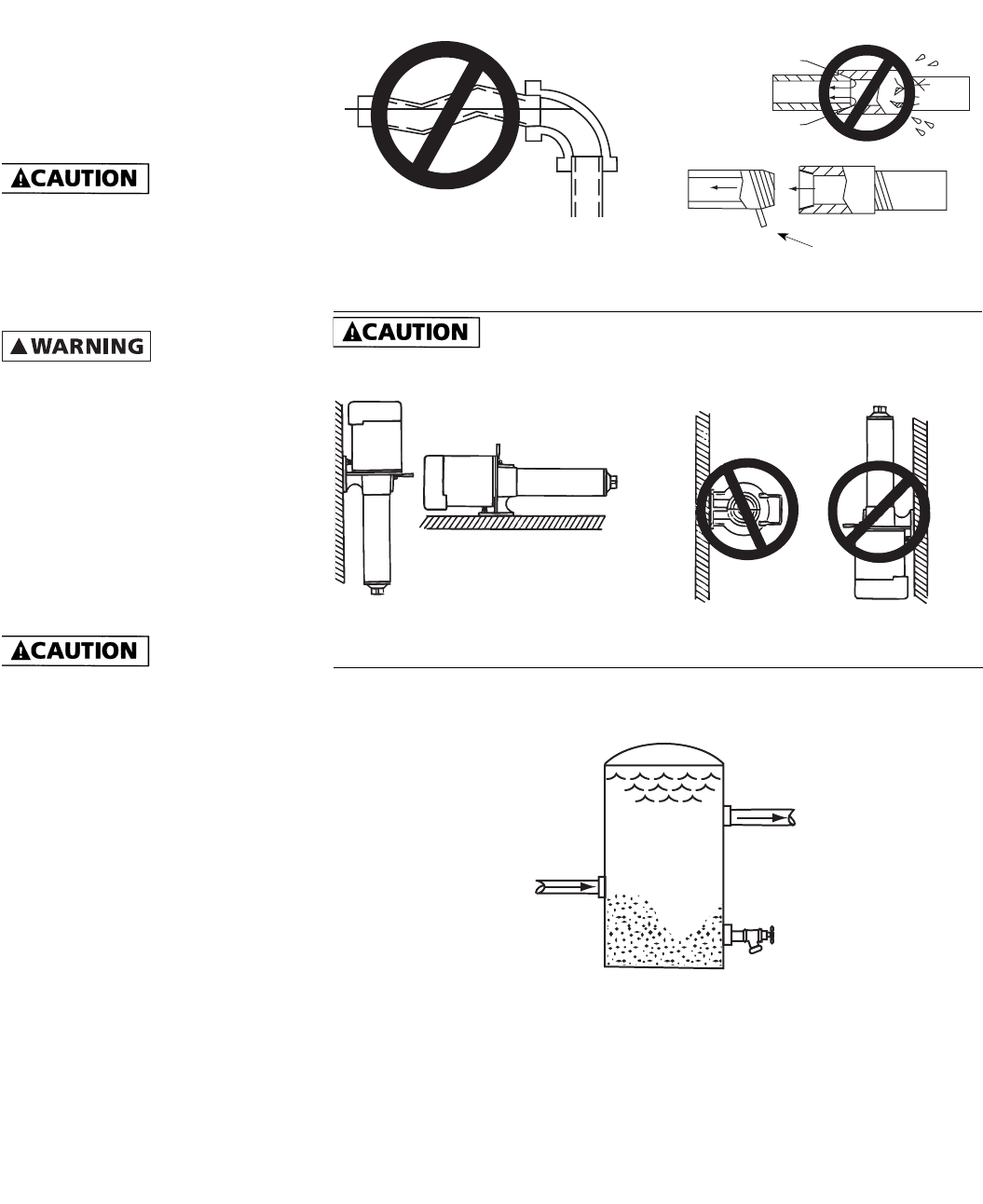

Figure 4A Figure 4B

IL0421

SAND AND SEDIMENT TRAP FILTER

Outlet

Clean Out

Standard Pressure

Tank - 42 Gallon Or

Larger

Inlet

Sand Settles To The Bottom

Installation

PUMP INSTALLATION

IMPORTANT: Pump is built to handle

clear water only; it is not designed to

handle water containing sand, silt or

other abrasives.

1.Refer to Figures 6, 7, and 8 for typi-

cal installations.

Support pump and

piping when assembling and when

installed. Failure to do so may cause

piping to break, pump to fail, motor

bearing failures, etc.

2. If the pump is used as part of a per-

manent installation, bolt to a rigid

foundation.

!

Use only compo-

nents that are rated for maximum pres-

sure pump can produce when used in

boosting system or any other system.

Do not exceed the total maximum

pressure boost as listed per model in

Performance Charts B.

PRESSURE BOOST SYSTEMS

1. On pressure boost systems, locate

the pump so that there will always

be a positive supply of water to the

pump (See Figures 6, 7 and 8).

2. For service convenience, install a

gate valve and union in the inlet

and discharge line.

Do not use a globe

valve or other restricting type of valve

that will seriously restrict the pumps

discharge capacity.

3. Install a check valve as shown in

Figure 6. Be sure check valve flow

arrows point in the direction of

water flow.

4. Whenever dirt, sand or debris is

present in the supply water, install a

strainer or filter on the inlet side of

the pump (See Figure 7).

NOTE: For heavy amounts of sedi-

ment, install a trap filter on the inlet

side of the pump (See Figure 5).

NOTE: Pressure gauges installed

before and after the filter will show

pressure differential indicating the

need for filter replacement or clean-

ing.