Heat & Glo • SLR • 2143-900 Rev. B • 7/08 48

WARNING! Risk of Fire! Maintain specifi ed air space

clearances to combustibles.

Failure to comply with these instructions may cause a

fi re or cause the appliance to overheat.

Ensure that the one inch back clearance and one inch

side clearances are maintained.

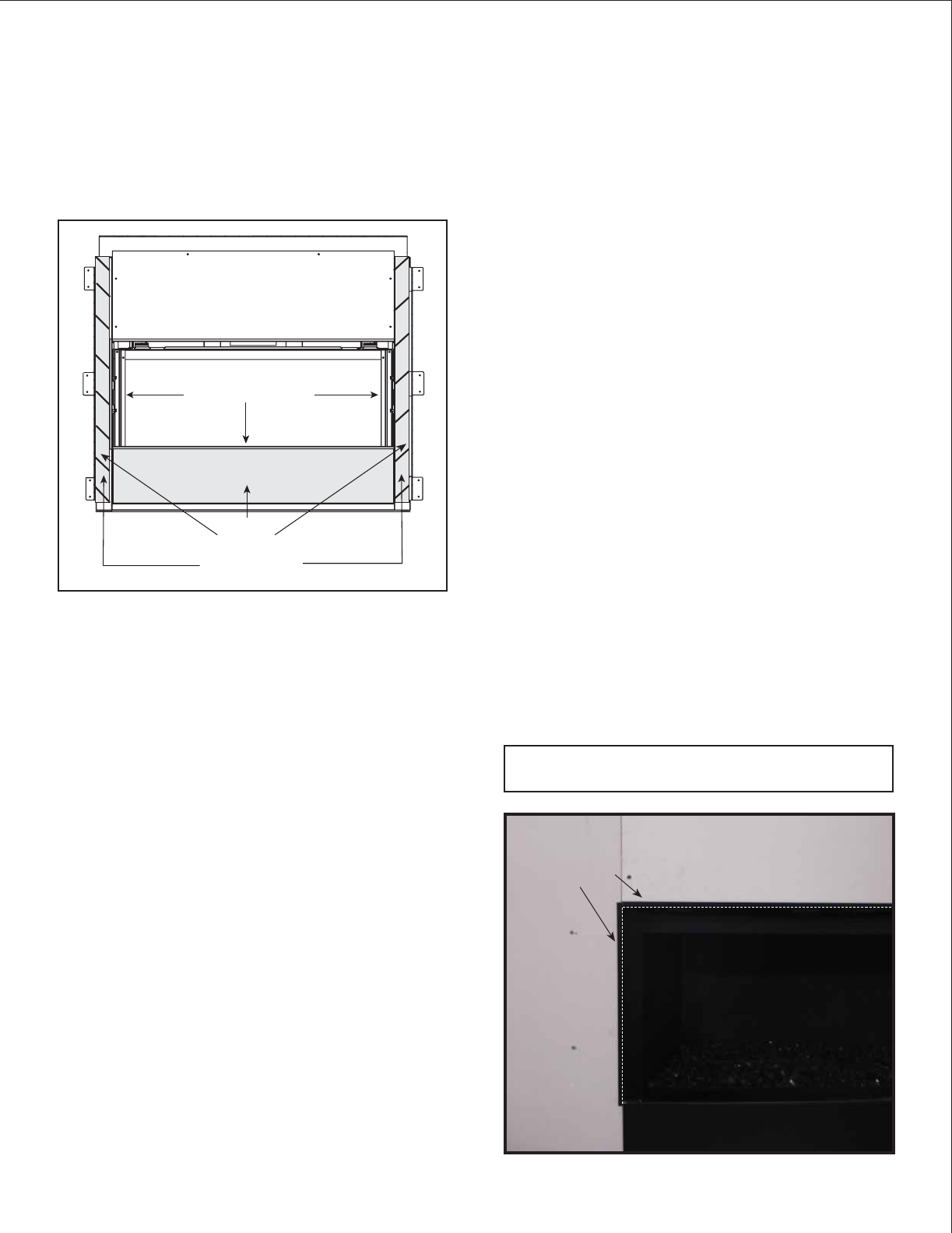

NON-COMBUSTIBLE BOARD

(PROVIDED WITH UNIT)

LOWER COVER PANEL

SIDE COLUMNS

NO

SCREWS

TOP FLANGE

FINISHING FLANGES

Figure 13.4 Finishing Details

Figure 13.5 Side Wall Sheathing Installed

CAUTION! RISK OF GLASS DAMAGE AND CUTS! DO

NOT DRILL OR INSTALL ANY TYPE OF SCREW OR

FASTENER INTO THE LOWER COVER PANEL. SHARP

SCREW OR FASTENER TIPS MAY PENETRATE AND

BREAK THE GLASS OR CAUSE CUTS.

The SLR can be fi nished using either the Tonic or

Martini decorative fronts. See Figures 13.17 and 13.18.

Depending on the decorative front, the fi nal fi replace

installation can be accomplished by either the “overlap”

or “inside-fi t” method. Reference Section 13.C regarding

installation details associated with the Inside and Overlap

Fit methods.

If the fi nal fi replace installation uses the Overlap Method,

wall sheathing material ½” thick is specifi ed and can

be installed tight to the side fi nishing fl anges. If the

fi nal fi replace installation uses the Inside-Fit Method,

additional clearance of 4” must be maintained between

combustible ½” thick wall sheathing material and the

side fi nishing fl anges. Reference Section 13.C regarding

installation details associated with the Inside and Overlap

Fit methods.

When fi nishing the wall around the fi replace, it is critical

that wall sheathing be fastened properly. Wall sheathing

fasteners, such as screws or nails, are not permitted in

some locations. See Figure 13.4. It is acceptable to

pre-drill holes and use self-tapped screws in the factory-

installed non-combustible board which may be used

to lathe (a backer for tile, marble, etc.) Screws being

installed through the factory-installed non-combustible

board should be self-tapping type with a minimum length

of 5” and maximum length of 7”. It is also acceptable

to penetrate the top fl ange with self-tapping screws.

See Figure 13.4. Do not drill or install screws into the

side columns as the existing stand-offs will support

the wall sheathing. Do not drill or install screws which

may penetrate the lower cover panel as this will restrict

required access to the glass, battery-back-up, and remote

receiver. See Figure 13.4.

The appliance is designed to accept ½” wall sheathing

materials such as drywall, plywood, wood composites,

or non-combustible materials. The type of material used

depends whether the installation is an Inside or Overlap

Fit method. Reference Section 13.C regarding installation

details associated with the Inside an Overlap Fit methods.

The left/right sides and bottom of the fi replace opening

include fi nishing fl anges that will interlock with ½” wall

sheathing. See Figure 13.4. The ½” thick wall sheathing

can be installed tight to the left, right, and bottom fi nishing

fl anges such that the rough edges of the sheathing

are tucked behind the fl anges. See Figure 13.5. It is

necessary to cut a ½” slot in the sheathing where it is

tucked tightly behind the lower fi nishing fl ange. See

Figure 13.7.

Verify that the lover cover panel is installed correctly, and

that the fi replace opening height is 16 in. See Figure 13.6.

NOTE: It is acceptable to use a high temperature sili-

cone sealant to adhere drywall to lower cover panel.

FINISHING

FLANGES

Î