25

The Quality Leader in Conditioning Air

Residential Split - 60Hz R22 &R410A

Rev.: 5 June, 2008

www.heatcontoller.com

Electrical - Line Voltage

WARNING! To avoid possible injury or death due to

electrical shock, open the power supply disconnect switch

and secure it in an open position during installation.

CAUTION!

Use only copper conductors for eld installed

electrical wiring. Unit terminals are not designed to accept other

types of conductors.

x WARNING! x

x CAUTION! x

Electrical - Line Voltage

All eld installed wiring, including electrical ground, must comply

with the National Electrical Code as well as all applicable local

codes. Refer to the unit electrical data for fuse sizes. Consult

wiring diagram for eld connections that must be made by the

installing (or electrical) contractor.

All nal electrical connections must be made with a length of

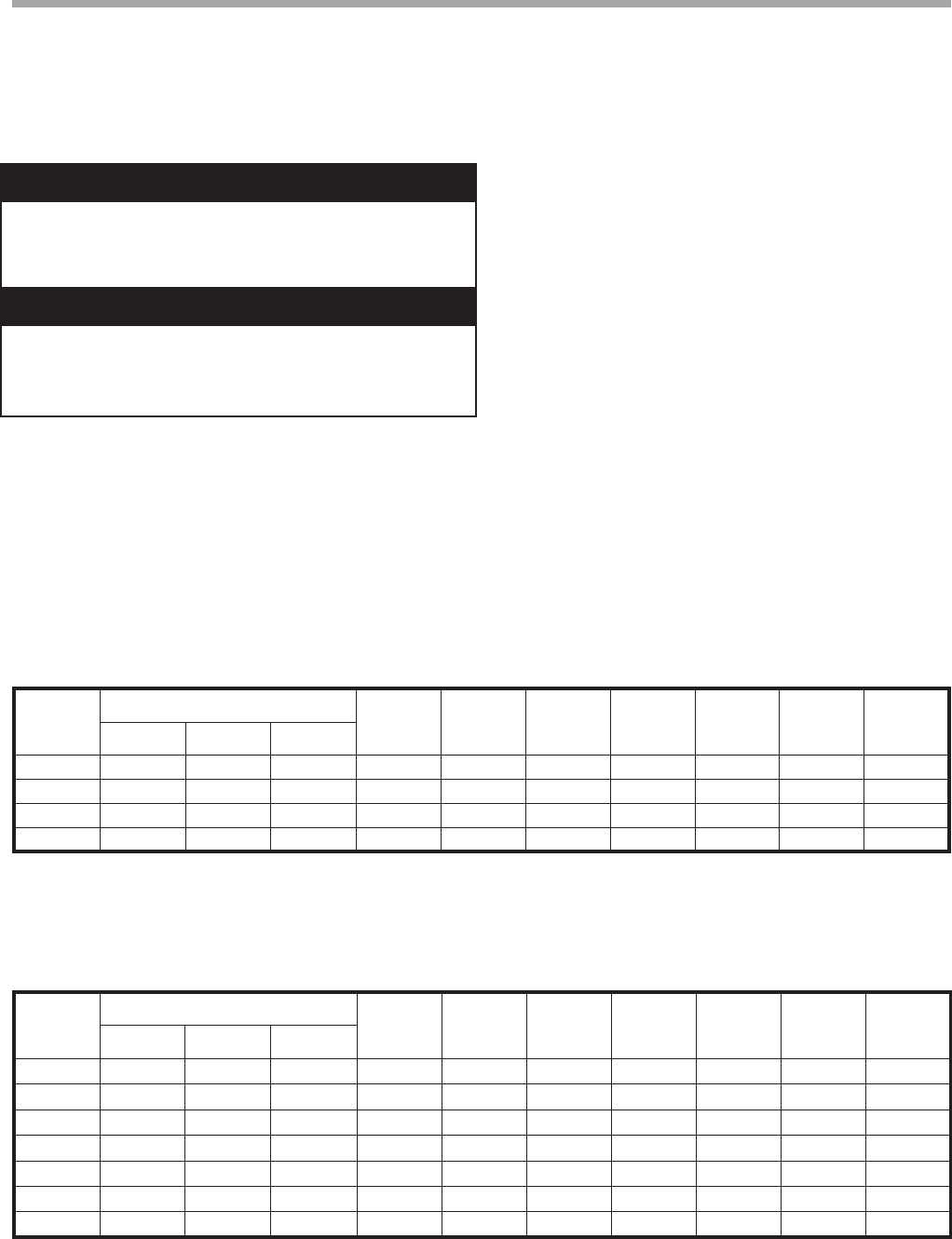

Table 8a: GeoMax 2 (HTS) Series Electrical Data

Table 8b: HSS Series Electrical Data

Model

Compressor

HWG

Pump

FLA

External

Pump

FLA

Total

Unit

FLA

Min

Circuit

Amps

Max

Fuse/

HACR

Min

AWG

Max Wire

Ft.

(m)

RLA LRA Qty

024 10.3 52.0 1 0.4 4.0 14.7 17.3 25 10 107 (32.7)

036 16.7 82.0 1 0.4 4.0 21.1 25.3 40 10 73 (22.3)

048 21.2 96.0 1 0.4 4.0 25.6 30.9 50 8 95 (29.2)

060 25.6 118.0 1 0.4 4.0 30.0 36.4 60 8 81 (24.8)

Rated Voltage of 208/230/60/1 Min/Max Voltage of 197/254

HACR circuit breaker in USA only All fuses Class RK-5

Wire length based on one way measurement with 2% voltage drop Wire size based on 60°C copper conductor and Minimum Circuit Ampacity.

Rated Voltage of 208/230/60/1 Min/Max Voltage of 197/254

HACR circuit breaker in USA only All fuses Class RK-5

Wire length based on one way measurement with 2% voltage drop Wire size based on 60°C copper conductor and Minimum Circuit Ampacity.

Model

Compressor

HWG

Pump

FLA

External

Pump

FLA

Total

Unit

FLA

Min

Circuit

Amps

Max

Fuse/

HACR

Min

AWG

Max Wire

Ft

(m)

RLA LRA Qty

018

7.7 40.3 1 0.40 4.0 12.1 14.0 20 12 76 (23.3)

024

10.3 56.0 1 0.40 4.0 14.7 17.3 25 10 107 (32.7)

030

12.2 67.0 1 0.40 4.0 16.6 19.7 30 10 94 (28.7)

036

13.5 73.0 1 0.40 4.0 17.9 21.3 35 10 87 (26.5)

042

16.5 95.0 1 0.40 4.0 20.9 25.0 40 10 74 (22.6)

048

18.3 109.0 1 0.40 4.0 22.7 27.3 45 10 67 (20.7)

060

25.0 148.0 1 0.40 4.0 29.4 35.7 60 8 82 (25.2)

exible conduit to minimize vibration and sound transmission

to the building.

General Line Voltage Wiring

Be sure the available power is the same voltage and phase

shown on the unit serial plate. Line and low voltage wiring

must be done in accordance with local codes or the National

Electric Code, whichever is applicable.

Power Connection

Line voltage connection is made by connecting the incoming

line voltage wires to the “L” side of the contactor as shown in

Figures 21a through 21c. Consult Tables 8a through 8c for

correct fuse size.

208-230 Volt Operation

Verify transformer tap with air handler wiring diagram to

insure that the transformer tap is set to the correct voltage,

208V or 230V.