HEAT CONTROLLER, INC. WATER-SOURCE HEAT PUMPS

Residential Split - 60Hz R22 &R410A

Rev.: 5 June, 2008

20

Heat Controller, Inc. Water-Source Heating and Cooling Systems

Refrigeration Installation

Table 6a: R-22 Charging Values

Table 6b: R-410A Charging Values

x NOTICE! x

NOTICE: Use tables 14a to 15 for superheat/subcooling

values. These tables use discharge pressure (converted

to saturation temperature) and liquid line temperature

for subcooling calculations. If using liquid line pressure,

subtract 3°F from the table values.

x NOTICE! x

NOTICE: Use tables 14a to 15 for superheat/subcooling

values. These tables use discharge pressure (converted

to saturation temperature) and liquid line temperature

for subcooling calculations. If using liquid line pressure,

subtract 3°F from the table values.

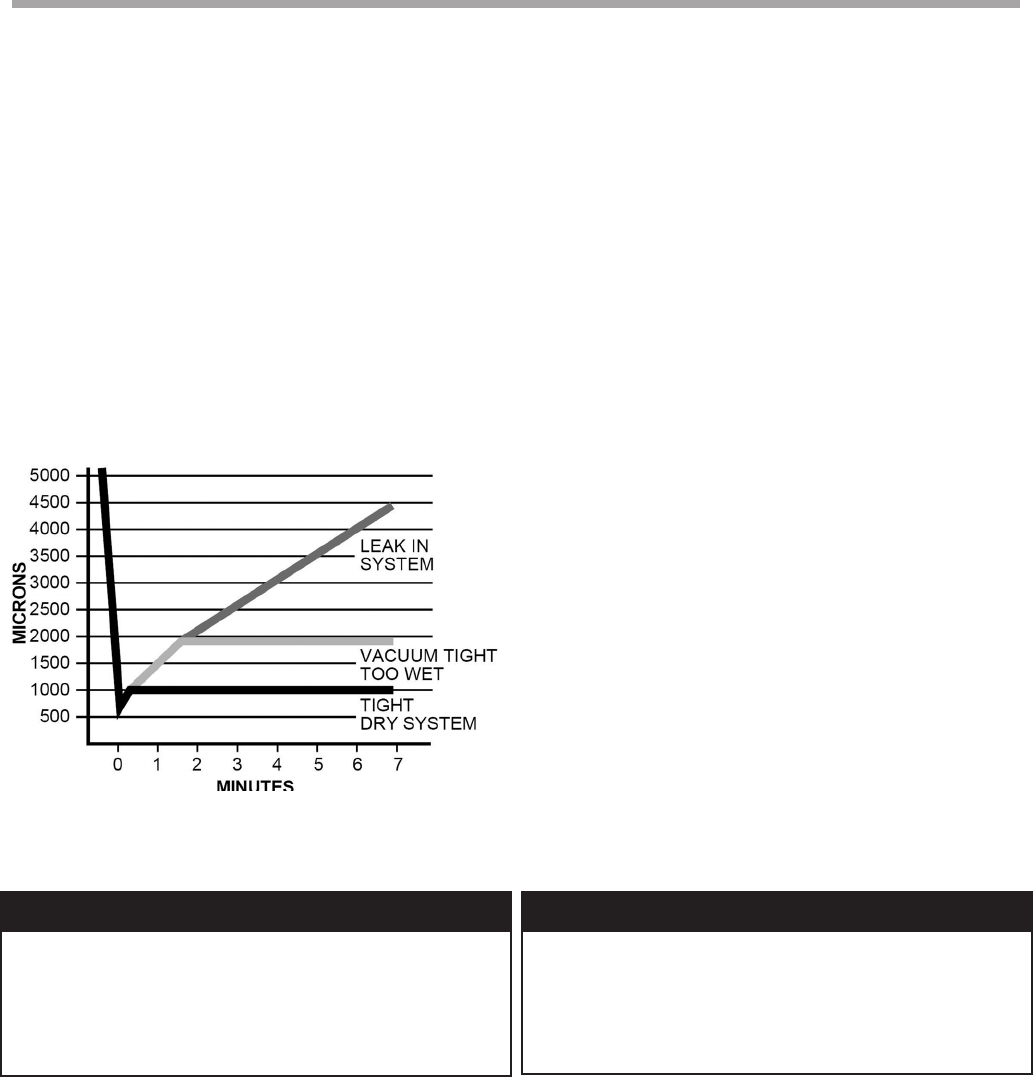

Evacuation Of The Lineset And Coil

The line set and coil must be evacuated to at least 500

microns to remove any moisture and noncondensables.

Evacuate the system through both service ports in the

shipping position (full CW in - see table 5) to prevent false

readings on the gauge because of pressure drop through

service ports. A vacuum gauge or thermistor capable of

accurately meausuring the vacuum depth is crucial in

determining if the system is ready for charging. If the system

meets the requirements in Figure 14, it is ready for charging.

Figure 14: Evacuation Graph

Charging The System

There are two methods of charging a refrigerant system. One

method is the total charge method, where the volume of the

system is determined and the refrigerant is measured and

added into the evacuated system. The other method is the

partial charge method where a small initial charge is added

to an evacuated system, and remaining refrigerant added

during operation.

Total Charge Method - See Table 4 for the compressor

section basic charge. For line sets with 3/8” liquid lines

add 0.6 ounces of refrigerant to the basic charge for every

installed foot of liquid line [0.6 grams per cm]. Add 1.2 oz.

per foot [1.1 grams per cm] if using l/2” line. Once the total

charge is determined, the factory pre-charge (Table 4) is

subtracted and the remainder is the amount needed to be

added to the system. This method should be used with the

ARI matched air handler.

EXAMPLE: R22 model 048 with 40 feet [12 meters] of

installed liquid line (3/8” O.D.). The basic charge of model

048 is 115 oz [3.26 kg]. The 40 ft. [12 meter] 3/8” line set

requires 24 oz. [0.72 kg] (40 ft. x 0.6 oz./ft = 24 oz. -- 1200cm

x 0.6g/cm = 720g). Total charge = 115 + 24 = 139 oz [3.26 +

0.72 = 3.98 kg]. The compressor section is shipped from the

factory with 130 oz. [3.69 kg] of refrigerant (for 25 ft [7.6m]

lineset), so the amount to be added is 9 oz. [0.29 kg] (total

charge - shipped charge = charge to be added).