12

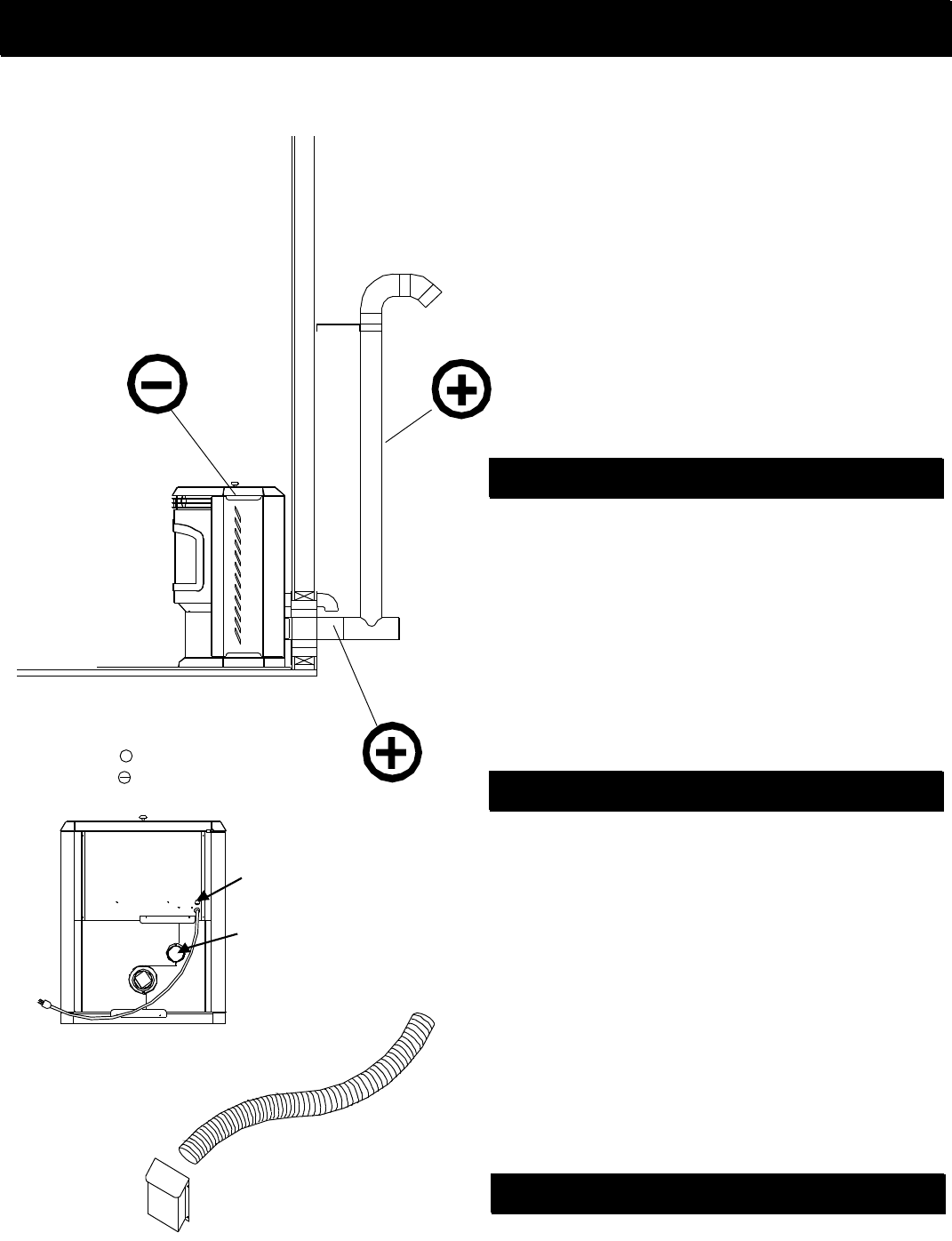

A combustion blower is used to extract the com-

bustion gases from the firebox. This causes a nega-

tive pressure in the firebox and a positive pressure

in the venting system as shown in fig. 19. The longer

the vent pipe and more elbows used in the system,

the greater the flow resistance. Because of these

facts we recommend using as few elbows as pos-

sible and 15 feet or less of vent pipe. The maximum

horizontal run should not exceed 48". If more than

15 feet of pipe is needed, the diameter should be

increased from 3" to 4" because a larger pipe causes

less flow resistance. Be sure to use approved

pellet vent pipe wall and ceiling pass- through

fittings to go through combustible walls and

ceilings. Be sure to use a starting collar to attach

the venting system to the stove. The starting col-

lar must be sealed to the stove with high temp

silicone caulking.

+ = Positive static pressure

= Negative static pressure

Outside air flex pipe

goes here

Inlet Cover part#

1-10-08542

Flex pipe part#

2-00-08543

HRV

When installing in a house with a Heat Reclaim-

ing Ventilation System (HRV) be sure the system is

balanced and is not creating a negative pressure in

the house.

Outside Air

Outside air is optional except in mobile homes

and where building codes require. The benefit of

outside air is mainly noticed in small, very tight

houses.

To install outside air use 2 3/8" I.D. flex pipe

part number 2-00-08543. There is a break-away hole

on the rear panel which must be removed before

connecting the flex pipe. The pipe should be run out-

side and terminate to the side or below the vent pipe

outlet so the flue outlet is more than 12" from the

inlet cover. The maximum length run of this pipe is

15 feet. If a longer run is needed, the size must be

increased to 3". Inlet cover part number 1-10-08542

should be used to keep birds, rodents, etc. out of

pipe.

Fig.19

Room Sensor

Connection Ports

Venting

Vent Pipe

Pellet venting pipe ( also known as PL vent ) is

constructed of two layers with air space between

the layers. This air space acts as an insulator and

reduces the outside surface temperature to allow a

clearance to combustibles of only 3 inches. The

sections of pipe lock together to form an air tight

seal in most cases; however, in some cases a per-

fect seal is not achieved. For this reason and the

fact that the Advance operates with a positive vent

pressure, we specify that the joints also be

sealed with clear silicone.

Evaluation notes were added to the output document. To get rid of these notes, please order your copy of ePrint IV now.