9

Burn Only the Fuel for which the Heater is Equipped

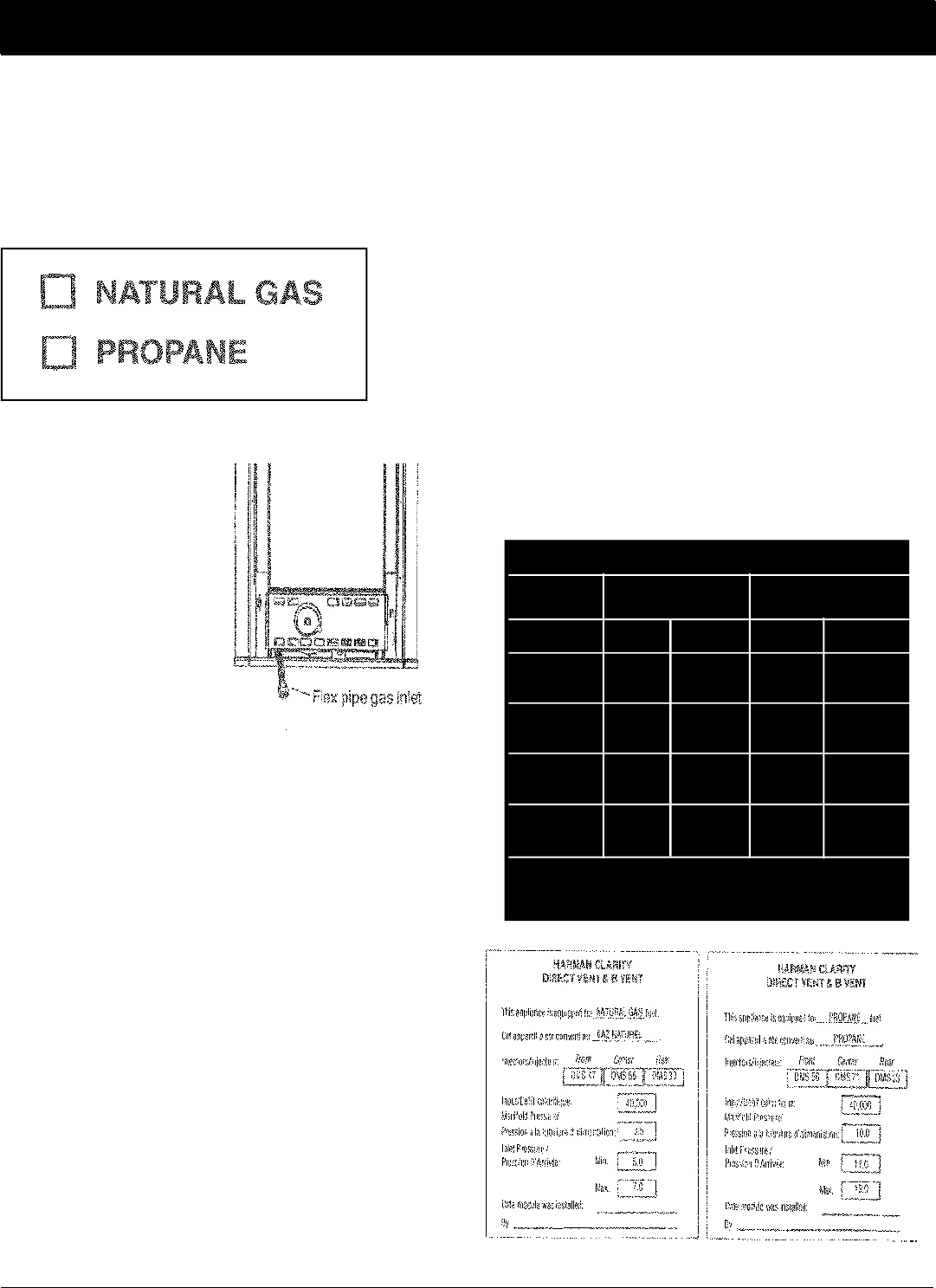

The Clarity Direct Vent will burn either natural gas or

propane, but requires a dedicated burner system module for

either fuel. The label on the burner system module indicates

the fuel for which it is equipped. A second label, located

near the rating plate, also indicates the fuel type.

Making The Connection

The gas inlet is located at

the bottom right rear of the

stove. The inlet fitting is a 1/

2" female flare flexible pipe.

A separate gas shut-off

valve and a 1/8" N.P.T.

plugged tapping should be

installed immediately up-

stream of the connection to

the appliance.

The Clarity Direct Vent

Gas Heater must be discon-

nected from the gas supply piping during any pressure test-

ing of that system at pressures in excess of 1/2 psig (3.5

kPa).

The Clarity gas control valve must be in the OFF position

during any pressure testing of the gas supply system at pres-

sures equal to or less than 1/2 psig (3.5 kPa).

WARNING: To avoid pipe compounds from en-

tering into the gas train, apply compounds only to male

pipe threads and do not apply compound to the first

two threads.

CAUTION: TEST ALL JOINTS FOR LEAKS BE-

FORE OPERATING

Gas Pressure Requirements

Correct gas pressure and the use of a properly sized

gas supply line are essential for the safe and efficient per-

formance of this appliance. Make sure that the plumber or

gas supplier checks the gas supply line and gas pressure at

installation.

NOTE: Improper gas pressure can affect heater per-

formance, flame color, or cause pilot outage.

Natural Gas:

Maximum inlet pressure 7.0" w.c. (1.74 kPa)

Minimum inlet pressure 5.0" w.c. (1.25 kPa)

Gas manifold pressure 3.5" w.c. (0.87 kPa)

LPG Gas:

Maximum inlet pressure 13" w.c. (3.24 kPa)

Minimum inlet pressure 11" w.c. (2.74 kPa)

Gas manifold pressure 10" w.c. (2.49 kPa)

DO NOT USE THIS HEATER IF ANY PART HAS

BEEN UNDER WATER OR EXPOSED TO MOISTURE

CORROSION. IMMEDIATELY CALL A QUALlFlED

SERVICE TECHNICIAN TO INSPECT THE HEATER

AND REPLACE ANY PART OF THE CONTROL SYS-

TEM AND ANY GAS CONTROL WHICH HAS BEEN

UNDER WATER.

Once you have installed the appropriate burner system

module, fill out the installer fuel label that was included with

the module, peel off the self-adhesive backing material, and

affix the label to the wing door near the rating plate.

Pipe Length Schedule 40 Pipe Tubing, Type L

(Feet) Inside Diameter Outside Diameter

N.G. L.P. N.G. L.P.

0-10 1/2" 3/8" 1/2" 3/8"

1.3 cm 1.0 cm 1.3 cm 1.0 cm

10-40 1/2" 1/2" 5/8" 1/2"

1.3 cm 1.3 cm 1.6 cm 1.3 cm

40-100 1/2" 1/2" 3/4" 1/2"

1.3 cm 1.3 cm 1.6 cm 1.3 cm

100-150 3/4" 1/2" 7/8" 3/4"

2.0 cm 1.3 cm 2.3 cm 2.0 cm

RECOMMENDED GAS PIPE DIAMETER

NOTE: NEVER USE PLASTIC PIPE. CHECK TO CONFIRM

WHETHER YOUR LOCAL CODES ALLOW COPPER

TUBING OR GALVANIZED PIPE.

CONNECTING THE HEATER TO A GAS SUPPLY

Evaluation notes were added to the output document. To get rid of these notes, please order your copy of ePrint IV now.