Instructions

14 3A1495C

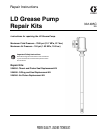

3. Pull spacer cylinder (36) away from pump to access

pin (8) (Fig. 36).

4. Use a rubber hammer and small punch to drive the

pin (8) out.

5. Unscrew the pump lower from displacement rod

(25). Set aside pump lower for reassembly.

6. Use a pick to remove gasket (30) from inside the

flange (22).

7. Continue pump disassembly instructions Steps 15 -

19, beginning on page 5.

8. Discard pin (8), air piston (15) and displacement rod

(25) according to all applicable safety regulations for

disposal of these parts.

Pump Reassembly

Always use all new parts included in the kit for reas-

sembly.

1. Apply a thin coat of grease around the threaded end

of the new displacement rod (25).

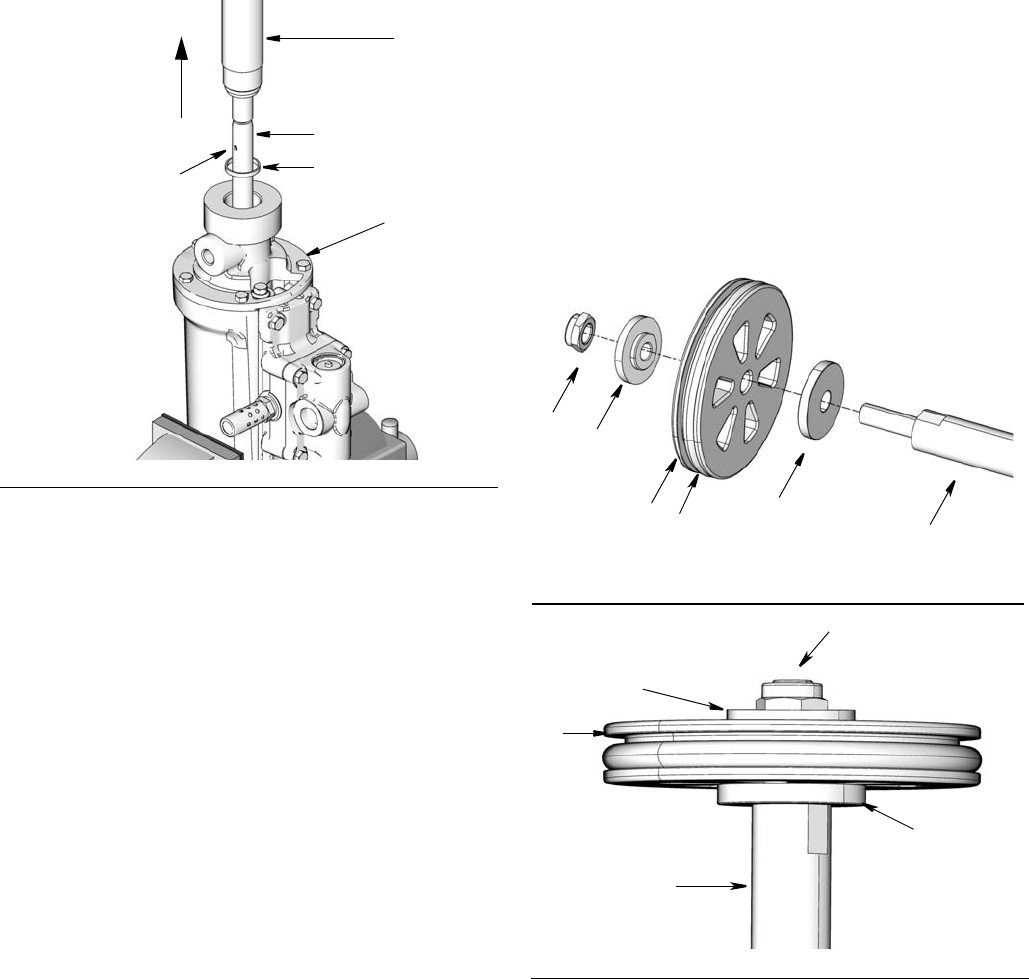

2. Assemble washer (38), air piston (15), gasket (13),

o-ring (5) and hex nut (19) to displacement rod (25)

as shown in Fig. 37. Be sure the male boss on gas-

ket (13) mates with the counter bore in air piston

(15). Tighten and torque nut (19) to 155 - 165 in.

pounds (17.5 - 18.6 N.m).

3. Apply a thin coat of grease around the chamfered

end of the displacement rod assembly (25). Push

the displacement rod through the opening in the bot-

tom cover and into the flange assembly as shown in

Fig. 36

22

36

PULL

8

30

25

Fig. 37

15

19

38

25

13

5

25

15

13

19

38