8 308981

Installation

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

This pump must be grounded. Before

operating the pump, ground the system

as explained below. Also read the sec-

tion Fire and Explosion Hazard on page 3.

The acetal Husky 515 pump contains stainless

steel fibers, which makes the wetted parts conduc-

tive. Attaching the ground wire to the grounding

screw (106) grounds the wetted parts. See

grounding screw on page 25.

The metal Husky 716 pumps have a grounding

strip connecting the vee clamps (109). Attach a

ground wire to the grounding strip with the screw,

lockwasher, and nut as shown in the Grounding

Detail on page 27.

The polypropylene and PVDF Husky 515 pumps

are not conductive.

When pumping conductive flammable fluids, al-

ways ground the entire fluid system by making

sure the fluid system has an electrical path to a

true earth ground (see Fig. 3). Never use a poly-

propylene or PVDF pump with non-conductive

flammable fluids as specified by your local fire

protection code.

US Code (NFPA 77 Static Electricity) recommends

a conductivity greater than 50 x 10

–12

Siemans/me-

ter (mhos/meter) over your operating temperature

range to reduce the hazard of fire. Consult your

fluid supplier to determine the conductivity or

resistivity of your fluid. The resistivity must be less

than 2 x 10

12

ohm-centimeters.

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equip-

ment.

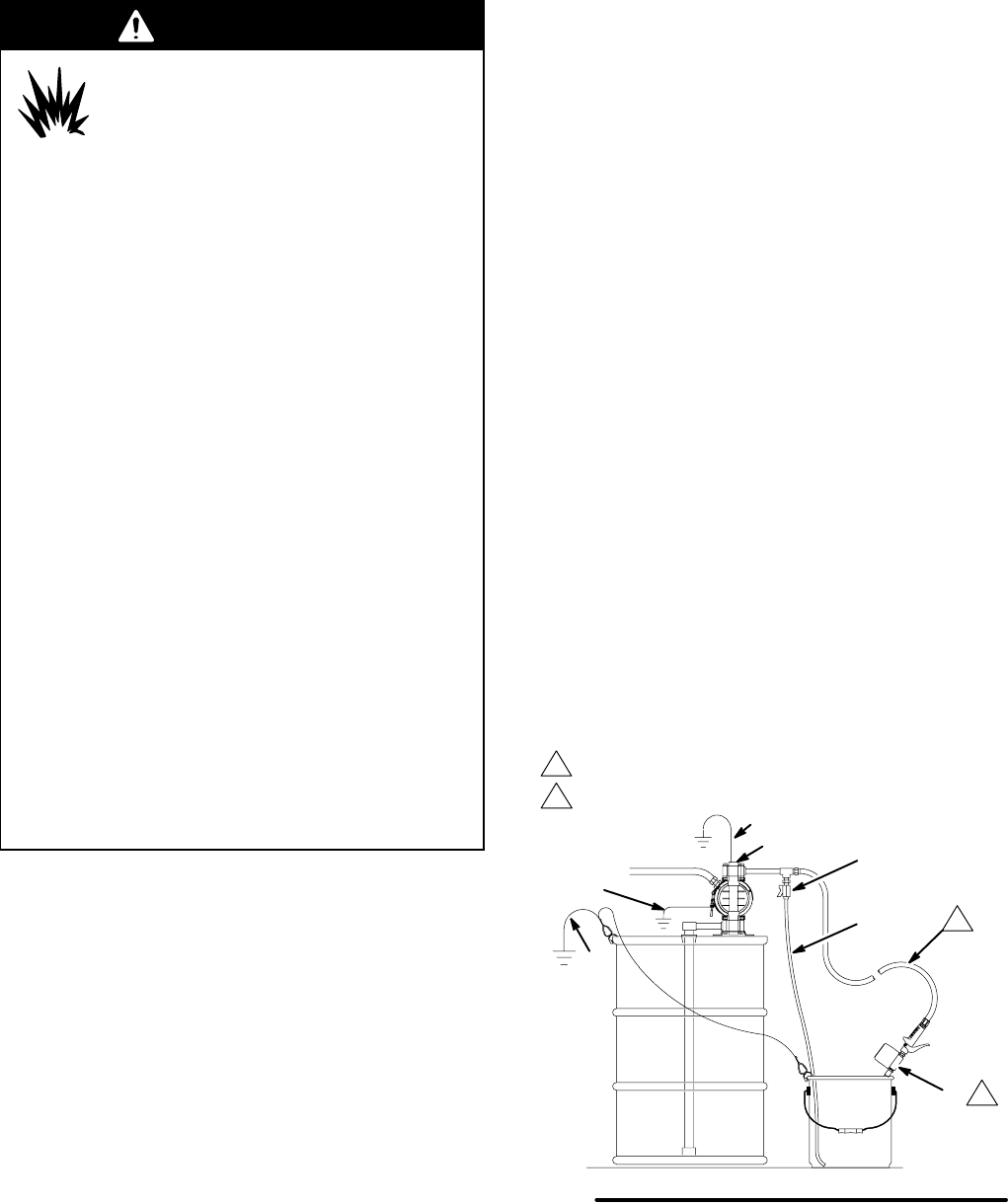

NOTE: When pumping conductive flammable fluids

with a polypropylene or PVDF pump, always ground

the fluid system. See the WARNING above. Fig. 3

shows a recommended method of grounding flam-

mable fluid containers during filling.

Ground all of this equipment:

D Pump: The metal pump has a grounding strip in

front of the center housing. The acetal pump has a

grounding screw on the top manifold. Connect the

non-clamp end of the ground wire to the grounding

strip or grounding screw, and connect the clamp

end of the ground wire to a true earth ground. To

order a ground wire and clamp, order Part No.

222011.

D Air and fluid hoses: Use only electrically conductive

hoses.

D Air compressor: Follow the manufacturer’s recom-

mendations.

D Solvent pails used when flushing: Follow the local

code. Use only grounded metal pails, which are

conductive. Do not place the pail on a non-conduc-

tive surface, such as paper or cardboard, which

interrupts the grounding continuity.

D Fluid supply container: Follow the local code.

9079A

KEY

A Pump

H Fluid drain valve (required)

S Dispense valve

T Fluid drain line

Y Fluid section grounding via grounding strip or grounding

screw (required for metal and acetal pumps)

Z Container ground wire (required)

Fig. 3

2

GROUNDING A PUMP

Dispense valve nozzle must be in contact with container.

A

H

S

T

Z

1

Hose must be conductive.

2

1

Y

Y