12

GAS PIPING CHECKS

T

O

PREVENT

PROPERTY

DAMAGE

OR

PERSONAL

INJURY

DUE

TO

FIRE

,

THE

FOLLOWING

INSTRUCTIONS

MUST

BE

PERFORMED

REGARDING

GAS

CONNECTIONS

AND

PRESSURE

TESTING

:

•T

HE

UNIT

AND

ITS

GAS

CONNECTIONS

MUST

BE

LEAK

TESTED

BEFORE

PLACING

IN

OPERATION

.B

ECAU SE

OF

THE

DANGER

OF

EXPLOSION

OR

FIRE

,

NEVER

USE

A

MATCH

OR

OPEN

FLAME

TO

TEST

FOR

LEA KS

.N

EVER

EXC EED

SPECIFIED

PRESSURES

FOR

TESTING

.

H

IGHER

PRESSURE

MAY

DAMAGE

GAS

VALVE

AND

CAUSE

OVERFIRING

WHICH

MAY

RESULT

IN

PREMATURE

HEAT

EXCH ANGE

FAILURE

.

•T

HIS

UNIT

AND

ITS

SHUT

‐

OFF

VALVE

MUST

BE

DISCONNECTED

FROM

THE

GAS

SUPPLY

DURING

ANY

PRESSURE

TESTING

OF

THAT

SYSTEM

AT

TEST

PRESSURES

IN

EXC ESS

OF

1/2PSIG(3.4 8

K

P

A

).

•T

HIS

UNIT

MUST

BE

ISOLATED

FROM

THE

GAS

SUPPLY

SYSTEM

BY

CLOSING

ITS

MANUAL

SHUT

‐

OFF

VALVE

DURING

ANY

PRESSURE

TESTING

OF

THE

GAS

SUPPLY

PIPING

SYSTEM

AT

TEST

PRESSURES

EQUAL

TO

OR

LESS

THAN

1/2PSIG(3.4 8

K

P

A

).

CAUTION

T

O

AVOID

PROPERTY

DAMAGE

OR

PERSONAL

INJURY

,

BE

SURE

THERE

IS

IN

THE

VICINITY

DURING

AIR

BLEED ING

.

NO

OPEN

FLAME

WARNING

There will be air in the gas supply line after testing for leaks

on a new installation. Therefore, the air must be bled from

the line by loosening the ground joint union until pure gas is

expelled. Tighten union and wait for five minutes until all gas

has been dissipated in the air. Be certain there is no open

flame in the vicinity during air bleeding procedure. The unit is

placed in operation by closing the main electrical disconnect

switch for the unit.

PROPANE GAS INSTALLATIONS

T

O

AVOID

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

DUE

TO

FIRE

OR

EXPLOSION

CAUSED

BY

A

PROPANE

GAS

LEA K

,

INSTALL

A

GAS

DETECTING

WARNING

DEVICE

.S

INCE

RUST

CAN

REDUCE

THE

LEVEL

OF

ODORANT

IN

PROPANE

GAS

,

A

GAS

DETECTING

WARNING

DEVICE

IS

THE

ONLY

RELIABLE

WAY

TO

DETECT

A

PROPANE

GAS

LEA K

.C

ONTACT

A

LOCAL

PROPANE

GAS

SUPPLIER

ABOUT

INSTALLING

A

GAS

DETECTING

WARNING

DEVICE

.

WARNING

IMPORTANT NOTE: Propane gas conversion kits must be

installed to convert units to propane gas.

All propane gas equipment must conform to the safety

standards of the National Board of Fire Underwriters (See

NBFU Manual 58). Line pressure 11.3 - 14” w.c.

For satisfactory operation, propane gas manifold pressure

must be within 9.7 - 10.3 inches w.c. for high fire and within

6.7 - 7.3 inches w.c. low fire at the manifold with all gas appli-

ances in operation. Maintaining proper gas pressure depends

on three main factors:

1. Vaporization rate, which depends on (a) temperature

of the liquid, and (b) wetted surface area of the

container or containers.

2. Proper pressure regulation.

3. Pressure drop in lines between regulators, and

between second stage regulator and the appliance.

Pipe size required will depend on length of pipe run

and total load of all appliances.

TANKS AND PIPING

Complete information regarding tank sizing for

vaporization, recommended regulator settings and pipe

sizing is available from most regulator manufacturers and

propane gas suppliers.

Since propane gas will quickly dissolve white lead or most

standard commercial compounds, special pipe dope

must be used. Shellac base compounds resistant to the

actions of liquefied petroleum gases such as Gasolac

®

,

Stalactic

®

, Clyde’s

®

or John Crane

®

are satisfactory.

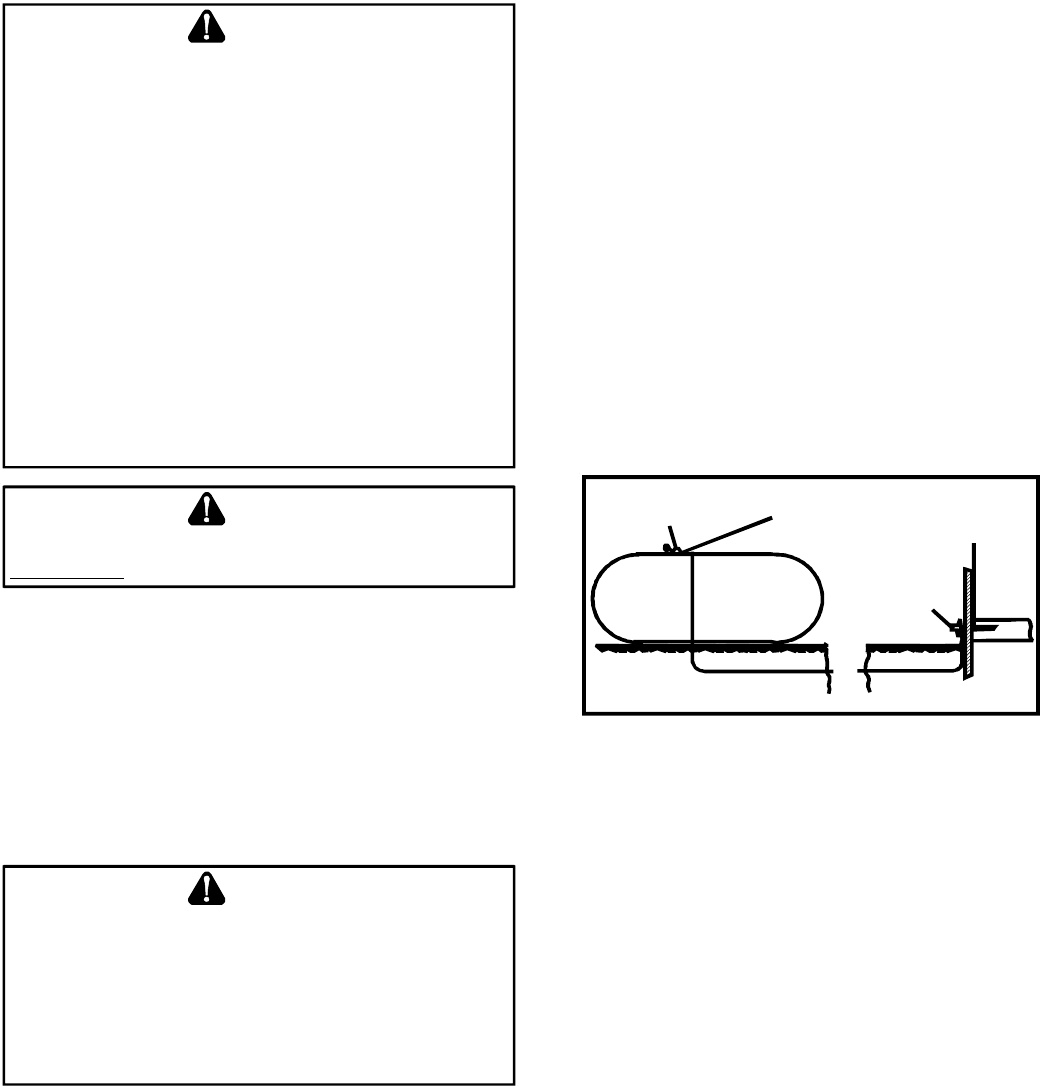

See following figure for typical propane gas piping.

200 PSIG

Maximum

5 to 15 PSIG

(20 PSIG Max.)

Continuous

11" W.C.

Second Stage

Regulator

First Stage

Regulator

TYPICAL PROPANE GAS PIPING

ROOF TOP LOCATION AND INSTALLATION

The gas supply piping location and installation for roof top

units must be in accordance with local codes or, in the ab-

sence of locals codes, with ordinances of the latest edition of

the National Fuel Gas Code (ANSI Z223.1).

A manual gas shutoff valve must be field installed external to

the roof top unit. In addition, a drip leg must be installed near

the inlet connection. A ground joint union connection is re-

quired between the external shutoff valve and the unit con-

nection to the gas valve to permit removal of the burner as-

sembly for servicing.

1. Route gas piping to unit so that it does not interfere

with the removal of access panels. Support and align

piping to prevent strains or misalignment of the

manifold assembly.

2. All units are furnished with standard female NPT pipe

connections. Connection pipe size is 3/4" NPT. The

size of the gas supply piping to the unit must be based

on length of run, number of units on the system, gas

characteristics, BTU requirement and available supply

pressure. All piping must be done in accordance with

local codes or, in the absence of local codes, with the

latest edition of the National Fuel Gas Code (ANSI

Z223.1).