035-18496-000-C-1102

Unitary Products Group 25

To check the supply air CFM after the initial balanc-

ing has been completed:

1. Drill two (2) 5/16-inch holes in the side panel as shown in

Figure 24.

2. Insert at least 8 inches of 1/4 inch tubing into each of

these holes for sufficient penetration into the airflow on

both sides of the evaporator coil.

3. Using an inclined manometer, determine the pressure

drop across a dry evaporator coil. Since the moisture on

an evaporator coil may vary greatly, measuring the pres-

sure drop across the wet coil under field conditions

would be inaccurate. To assure a dry coil, the refrigerant

system should be de-activated while the test is being

run.

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determined from the curves

shown in Figures 25-28.

If the CFM is above or below the specified value, the supply

air motor pulley may have to be readjusted. After one hour of

operation, check the belt and pulleys for tightness and align-

ment.

After readings have been obtained, remove the tubes and

seal up the drilled holes in the side panel. 5/16 inch dot plugs

(P/N 029-12880) are available through normal York parts

ordering procedures.

Failure to properly adjust the total system air

quantity can result in extensive blower dam-

age.

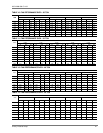

FIGURE 25 - HOLE LOCATION FOR PRESSURE

DROP READING

5/16"

HOLE

5/16"

HOLE

"

7"

25"

14"

EVAPORATOR

COIL

FILTERS

COIL SECTION

22