035-18496-000-C-1102

18 UnitaryProductsGroup

PUMP OUT

The pump out function is a standard feature on the 25 to 50

ton systems. The pump out circuit is activated each time the

first and third compressor stage is called for by the thermo-

stat. As such, it’sa“Pump Out On Start Up” design. A nor-

mally closed solenoid valve (POS1, 2, 3 or 4) is placed in the

liquid line, just prior to expansion valve.

When cooling is not being called for by the thermostat, the

pump out solenoid (POS) is not energized, so it’sinthe

closed position. When the Simplicity™ control receives a call

for cooling, it energizes a compressor. With the POS being

closed, it causes the pressure on the low side of the system

to begin falling.

When the low pressure switch (LPS) opens, the control board

energizes its on-board pump out relay, providing a 24 vac

output to an external relaly used to energized the pump out

solenoid. The refrigeration circuit being controlled is not in

normal operating mode.

If the low pressure switch is already open on a call for cool-

ing, the pump out relay is energized immediately. If the LPS

does not open after 5 minutes, the pump out relay is ener-

gized.

BEARING ALIGNMENT: LB600

Before the supply air blower drive is installed, turn the blower

assembly by hand several times. If it doesn't rotate freely, the

center bearing may have been knocked out of alignment dur-

ing shipping and/or rigging. To realign, refer to 15 and the fol-

lowing instructions:

1. Loosen the bearing collar set screw.

2. With a drift pin in the bearing collar removal hole, loosen

the bearing collar by tapping the drift pin in the direction

opposite to the shaft rotation.

3. Loosen bolts "A" and "B".

4. Remove the shim.

NOTE: The bearing support angle must be horizontal

to the unit and below the bearing.

5. Tighten bolts "B" without the shim.

6. Tighten bolts "A".

7. With a drift pin in the bearing collar removal hole, tighten

the bearing collar by tapping the drift pin once in the

direction of the shaft rotation.

8. Tighten the bearing collar set screw.

9. Loosen bolts "B"

10. Raise the blower shaft and re-install the shim between

the bearing and the bearing support angle.

11. Tighten bolts "B".

AIR SYSTEM ADJUSTMENT

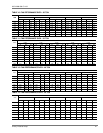

Refer to Tables 7-11 on pages 19-20 to adjust the air system.

TWIN BELT DRIVE ADJUSTMENT

Check to see if both belts drive at the same speed. Do this

by making a mark across both belts. Turn the drive several

revolutions by hand. If mark has not separated, the belts are

traveling at the same speed.

Twin groove blower motor pulleys should be installed with the

shaft set screw (A) towards the motor (see 16).

If necessary to align pulleys, the housing of the twin groove

motor pulley may extend 25% of its length beyond end of

motor shaft.

Always align twin groove pulleys using the stationary web.

The blower motor pulleys are adjustable by half turns. Select

required RPM from table 5 and adjust pulley.

FIGURE 15 - LB600 CENTER BEARING

FIGURE 16 - DOUBLE GROOVE PULLEY

SHAFT

ROTATION

BEARING COLLAR

SET SCREW

BEARING

COLLAR

BLOWER

SHAFT

BOLT "B" BOLT "B"

BEARING

BEARING

COLLAR

REMOVAL

HOLE

BEARING SUPPORT ANGLE

SHIM

BOLT "A"

A

B

B

C

D

E

STATIONARY WEB

C