Troubleshooting

3. The stove will not function in the “AUTO” mode when hot.

w If the unit fails to operate, by-pass the auto side of the switch by inserting a jumper wire between the

dual black wires and the dual brown wires located on the back of the switch. Plug the stove back in.

If the stove operates, replace the switch.

w Check the hopper for fuel.

w Incorrect air damper setting - Excessive air may consume the fire too quickly before the next drop of

fuel, leaving completely unburned fuel in the burn pot liner. Insufficient air will cause build up, further

restricting the air flow through the Burn Pot Liner. This in turn will cause the fuel to burn cold and very

slowly. Fuel may build up and smother the fire. (NOTE: Unit may require a change to the vent

system or installation of fresh air to correct Air to Fuel ratio problems).

w Combustion Blower failure - The Combustion Blower is not turning fast enough to generate the proper

vacuum in the fire box. Visual Check – is the blower motor turning?

w Check Vacuum levels in the exhaust channel by bypassing the Vacuum Switch, then remove the

Vacuum hose from Vacuum Switch. Check exhaust vacuum readings by placing the open end of the

Vacuum Hose on a Magnahelic Gauge (readings must be above 0.10” W.C. on low fire).

Note: If the motor fails to reach a 0.10” W.C. reading, then replace the Combustion Blower.

w Poor Quality Fuel – Insufficient energy in the fuel to produce enough heat to keep the stove burning

or operational.

w Exhaust Temperature Sensor failure – Bypass sensor located on Exhaust Blower. If stove now operates

properly, the unit may require cleaning or a new sensor. Contact your local dealer for service.

w The unit may require cleaning. Contact your local dealer for service.

4. The exhaust motor will not function normally.

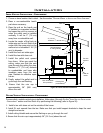

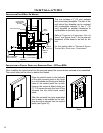

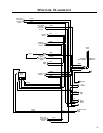

w Open the left side access panel; check all connections against the wiring diagram.

w If all the connections are verified and the exhaust blower does not function at all, tap lightly on the

exhaust blower’s motor end cap, this may loosen a tight motor.

w Apply 115 V AC directly to the exhaust blower. If the motor does not run, replace the blower.

w If the motor runs, have your dealer check the harness.

w Contact your local dealer for service.

5. The convection blower will not function normally.

w Check all the connections between the controller, switch, and the convection blower against the wiring

diagram.

w If the convection motor will not run, apply 115 V AC to the motor directly. If the motor runs, replace

the fan controller. If the motor does not run, the convection blower has failed. Replace the blower.

w If the convection blower runs on high at all times (no control with the fan controller), check the

connections from the 160°F (71°C) sensor (located on the upper left side of the firewall) and

convection fan controller to the blower. Disconnect one of the wires from the sensor; if control of the

convection blower returns to the fan controller, replace the sensor.

w If the motor is still on high, re-connect the sensor and replace the convection fan controller.

28