9

13. Place casing gasket (351) against shoulder in casing.

14. Slide the pullout assembly into the casing (100). Drain slot

in stuffing box cover (184) should line up with drain connection

in casing. Install frame–to–casing bolts (370) and tighten evenly

while rotating shaft (122) by hand. If impeller ceases to turn

freely, stop tightening operation and adjust the impeller setting

with the adjusting bolts (370C and 370D) before resuming

tightening of frame-to-casing bolts (370).

15. Impeller Clearance

The impeller clearance is an important factor in maintaining

optimum pump performance. The nominal clearance is .015”

with the recommended minimum being .008”. The actual

clearance setting is dependent on the specific operating

conditions, taking into account temperature, solids, etc. For

maximum service flexibility pumps are shipped from the factory

with the clearance set at .015”. The desired clearance is

obtained in the following manner:

a. Loosen bolts (370C and 370D).

b. Tighten bolts (370C) with turning shaft clockwise until

impeller starts to rub against casing.

c. Loosen bolts (370C) until a feeler gauge, corresponding

to the desired clearance, can be placed between the bolt

head and bearing housing.

d. Tighten bolts (370D) evenly. Bearing housing shaft and

impeller will be jacked to proper clearance from casing.

Tighten bolts (370C) and jam nuts on bolts (370D).

e. If desired, a dial indicator can be used instead of a feeler

gauge to check that the bearing housing has been moved

the correct distance.

V-D. Additional Details

An alternate method for setting inside mechanical seals is the

“Modified Visegrip Method”.

1. Follow assembly up to Step 7.

2. Assemble the gland with stationary seat and gaskets.

3. Install the shaft sleeve, if used on the shaft, and engage

groove in sleeve with drive pin (469) on shaft.

4. Slide gland assembly over the shaft or shaft sleeve.

5. Install the stuffing box cover and impeller. Establish a

preliminary rotor adjustment (refer to Section V–C–9).

6. Slide gland assembly against stuffing box. Do not bolt the

gland to the stuffing box.

7. Clamp the modified visegrip on the shaft or sleeve directly

behind and against the gland.

8. Leave the visegrip in place and remove the impeller and

stuffing box cover.

9. Lubricate the rotary portion of seal and slide it on the shaft

until it comes in contact with the stationary seat in the gland.

10. Compress rotary portion of seal to correct dimension as

shown on seal manufacturer’s drawing. Tighten set screws.

11. Remove visegrip and reinstall stuffing box cover and

tighten.

12. Reinstall impeller with O–ring.

13. Slide the gland assembly against the stuffing box and tighten

nuts evenly.

14. Refer to Step 12, etc.

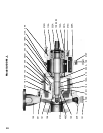

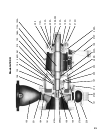

SECTION VI—PRODUCT DESCRIPTION

See pages 10, 11,12, 13 and 14 for Sectional

Views, Parts List and Materials of Construction.