5

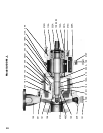

PRIOR TO COUPLING DRIVER TO PUMP, ROTATION OF

DRIVER SHOULD BE CHECKED! Serious damage can result

if pump is rotated in wrong direction. Once motor rotation

is checked, connect coupling, following the manufacturer’s

instructions. If a coupling guard is furnished with the unit,

ensure that it is securely fastened in place.

II-F. Stufng Box

1. Packing:

If the pumpage is dirty or hot, it is not suitable to lubricate the

packing. An external source must be utilized, unless the bypass

is equipped with proper separator, filter, and/or cooling system.

This must be piped into the lantern ring connection, also (refer

to packing recommendations).

2. Mechanical Seals:

When mechanical seals are supplied, they are installed and

adjusted at the factory. They must not run dry or in abrasives.

Connect recirculation, flush and/or cooling lines as required,

following instructions on the seal print supplied for the unit.

III-A. Startup

1. Check List

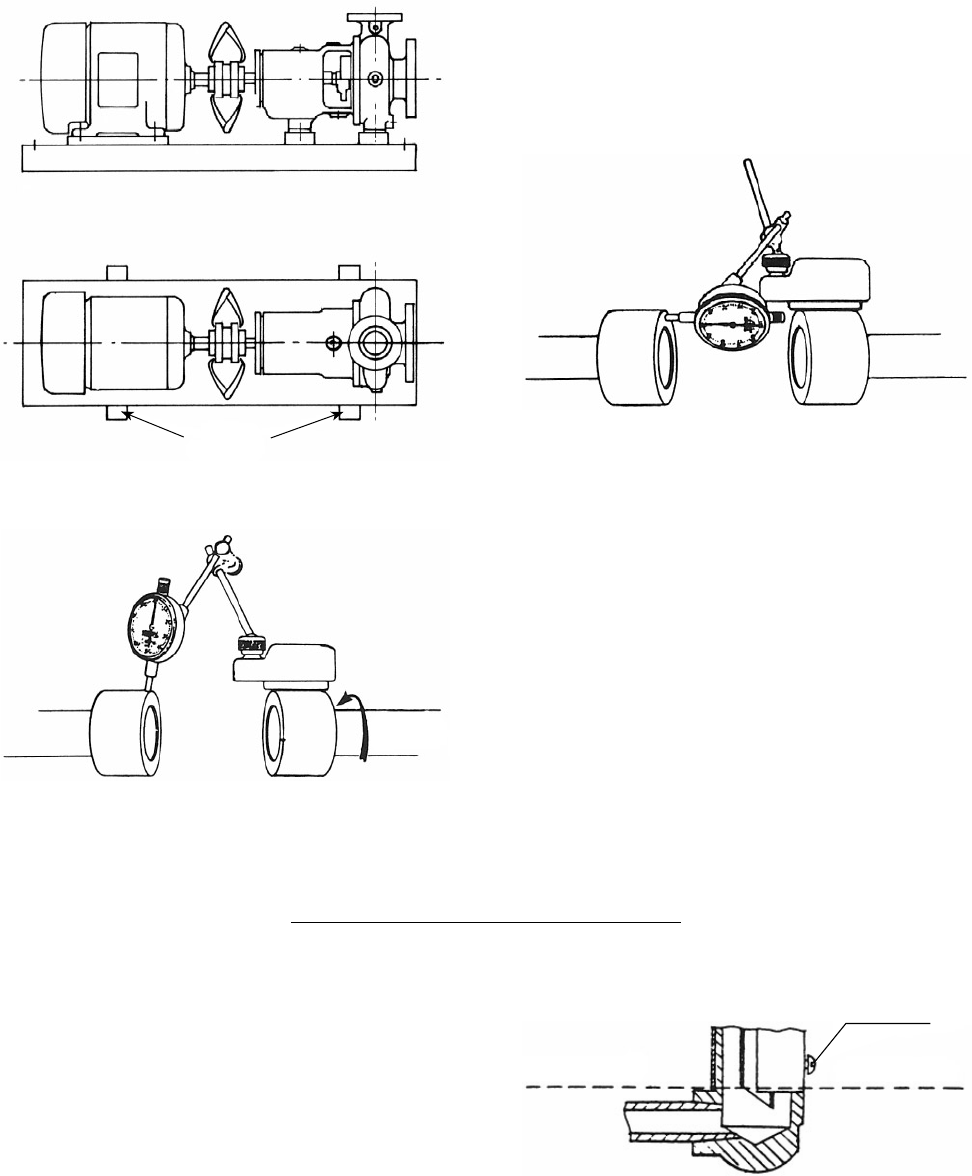

a. Lubrication—Pump bearings are normally oil lubricated.

(THE BEARINGS ARE NOT LUBRICATED AT THE

FACTORY.) These pumps are supplied with an oiler which

maintains a constant oil level in the bearing frame. Locate

oiler as shown on the outline drawings supplied for the

unit. See Fig. 6 for correct adjustment of oiler.

SECTION III—OPERATION

Figure 3

Figure 5

Figure 6

Figure 4

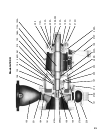

R O T AT E

THIS HUB

Figure 4

OIL LEVEL

OIL LEVEL

SET SCREW

WEDGES