8

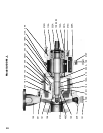

4. On S, M and L models, insert retaining ring (361A) into

groove in bearing housing (134A). Flat side of retaining ring

must be against bearing (112A). On X units, slide bearing end

cover (109A) and gasket (360C) on shaft. Ensure the “top” of

end cover (109A) lines up with the “top” of bearing housing

(134A), check scribe marks. If the bearing housing (134A) is

not installed properly (oil drain groove in bottom), oil will not

be able to drain from bearing causing it to overheat and fail

prematurely.

5. Oil inboard bearing seat on shaft. Slide inboard ball bearing

(168A) on shaft (122) as far as possible by hand. Continue as

in Step 1 above.

6. Place a small amount of O–ring lubricant on inside of

bearing frame (228A) at bearing housing (134A), at inboard

bearing seats (168A), on O-ring (496), and on inboard oil seal

(333A). Carefully slide shaft assembly into bearing frame. Do

not damage inboard oil seal (333A). Screw bearing housing

bolts (370C) about ” into bearing frame (228A) .

7. Slide deflector (123) on shaft (122).

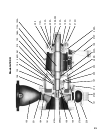

8. If unit has packed stuffing box, place stuffing box cover (184)

against adapter (108), making sure that studs (370H) align with

proper holes in adapter. Replace nuts and firmly tighten. Slide

sleeve (if any) on shaft. Make sure grooves in end of sleeve

engage drive pin on shaft. Continue assembly at Step 10.

9. If unit has mechanical seal:

The following instructions refer to pumps equipped with

mechanical seals, either with or without sleeves.

If the unit has a single inside or double seal, a preliminary impeller

adjustment must be performed to assure proper positioning of

mechanical seal.

(1) Position sleeve (126), if any, on shaft (122) and engage

groove in sleeve with drive pin (469) on shaft. Place

stuffing box cover (184) against frame (228). Make sure

studs (370H) align with proper holes in frame. Firmly

tighten nuts or bolts.

(2) Screw impeller (101) with O-ring (412A) in place on shaft.

Make sure that shaft assembly extends through stuffing

box cover (184) so that the impeller will NOT contact

face of stuffing box cover.

(3) Using impeller adjusting bolts (370C and 370D), adjust

the impeller end clearance 0.015 with volute in place.

Mark shaft sleeve.

The following instructions are for three basic seal types:

Single Inside, Single Outside, and Double Seals. Refer to seal

manufacturer’s drawing seal type and positioning dimension.

Follow pertinent procedures.

a. Single Inside Seal

(1) Scribe the shaft (122) or shaft sleeve (126) lightly at

the face of the stuffing box.

(2) Remove the impeller and stuffing box.

(3) Assemble the gland (250) with gaskets and stationary

seat and slide the assembly over the shaft (122) or

shaft sleeve (126).

(4) Slide the rotary portion of the seal on the shaft (122)

(or shaft sleeve) (126) establishing its location from

the scribe line to the dimension as shown on the seal

manufacturer’s drawing. Tighten set screws.

(5) Reinstall the stuffing box cover and tighten. Do not

damage the seal parts.

(6) Reinstall the impeller with O-ring.

(7) Slide the gland assembly against the stuffing box and

tighten the nuts evenly. Do not damage the seal

parts.

(8) Refer to Step 12 for further assembly details.

b. Double Seals

(1) Scribe the shaft (122) or shaft sleeve (126) lightly at

the face of the stuffing box.

(2) Remove the impeller and stuffing box.

(3) Assemble the gland (250) with gaskets and stationary

seat and slide the assembly over the shaft (122) or

shaft sleeve (126).

(4) Slide the rotary portion of the seal on the shaft (122)

or shaft sleeve (126) establishing its location from

the scribe line to the dimension as shown on the seal

manufacturer’s drawings. Tighten set screws.

(5) Place inboard stationary seat and gaskets into bottom

of stuffing box.

(6) Reinstall the stuffing box cover and tighten. Do not

damage seal parts.

(7) Reinstall the impeller with O–ring.

(8) Slide the gland assembly against the stuffing box and

tighten the nuts evenly. Do not damage seal parts.

(9) Refer to Step 12 for further assembly details.

c. Single Outside Seal

Preliminary impeller adjustment is not necessary with this

type of mechanical seal.

(1) If unit has shaft sleeve (126), slide on shaft (122)

and engage groove in sleeve with drive pin (469) on

shaft.

(2) Lubricate rotary portion of seal and slide on shaft

sleeve. Do not tighten set screws.

(3) Assemble gland (250), gaskets, and stationary seat

and slide assembly on shaft or sleeve.

(4) Place stuffing box cover (184) against frame making

sure that the studs (370H) align with the proper holes

in frame. Firmly tighten nuts.

(5) Screw impeller with O–ring on shaft making sure

impeller does not make contact with stuffing box

cover. If the impeller does hit, use impeller adjusting

cap screws to correct.

(6) Place gland assembly against face of stuffing box and

firmly tighten stud nuts.

(7) Slide rotary portion toward gland until it contacts

stationary seat. Compress the rotary. Tighten screws.

10. Screw impeller (101) with O–ring (412A) in place, on the

shaft (122).

11. On units with stuffing box packing (106), repack stuffing

box as outlined in Section II–F. Assemble gland stud nuts finger

tight.

12. Install and position coupling hub at scribe mark on shaft.