14

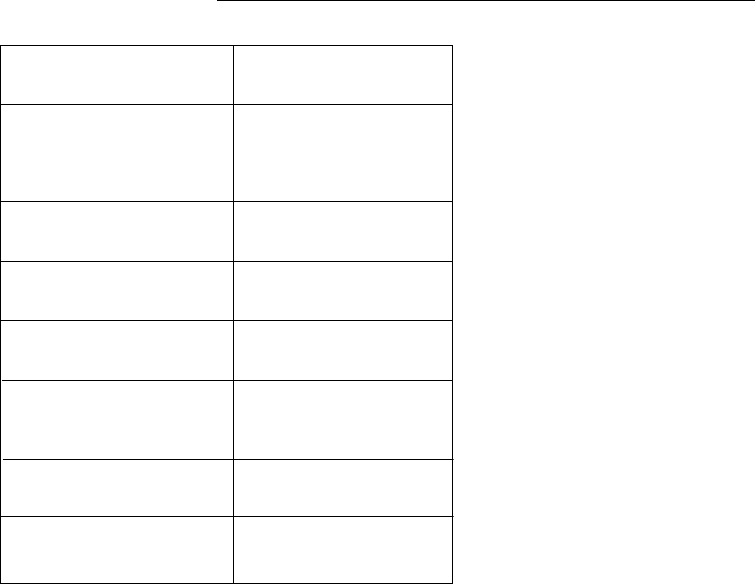

Causes & Corrective Measures

1. Pump not primed or properly vented—check that casing and

suction pipe are completely filled with liquid.

2. Speed too low—check whether motor wiring is correct and

receives full voltage or turbine receives full steam pressure.

3. System discharge head too high—check system head

(particularly friction losses).

4. Suction lift too high—check NPSH available (suction piping

too small or long may cause excessive friction losses). Check

with vacuum or compound gauge.

5. Impeller or piping obstructed—check for obstructions.

6. Wrong direction of rotation—check rotation.

7. Air pocket or leak in suction line—check suction piping for

air pockets and/or air leaks.

8. Stuffing box packing or seal worn allowing leakage of air into

pump casing—check packing or seal and replace as required.

Check for proper lubrication.

9. Not enough suction head for hot or volatile liquids—increase

suction head, consult factory.

SECTION VII—TROUBLE SHOOTING

10. Foot valve too small—install correct size foot valve.

11. Foot valve or suction pipe not immersed deep enough—

consult factory for proper depth. Use baffle to eliminate

vortices.

12. Entrained air or gases in liquid—consult factory.

13. Impeller clearance too great—check for proper clearance.

14. Impeller damaged—inspect and replace as required.

15. Rotating parts bind—check internal wearing parts for proper

clearances.

16. Shaft bent—straighten or replace as required.

17. Coupling or pump and driver misaligned—check alignment

and realign if required.

18. Impeller diameter too small—consult factory for proper

impeller diameter.

19. Improper pressure gauge location—check correct position

and discharge nozzle or pipe.

20. Casing gasket damaged—check gaskets and replace as

required.

21. Speed too high—check motor winding voltage or steam

pressure received by turbine.

22. Head lower than rating; pumps too much liquid—consult

factory. Install throttle valve, cut impeller.

23. Liquid heavier than anticipated—check specific gravity and

viscosity.

24. Stuffing box not properly packed (insufficient packing, not

properly inserted or run in, packing too tight)—check packing

and repack stuffing box.

25. Incorrect packing or mechanical seal—consult factory.

26. Damaged mechanical seal—inspect and replace as required.

Consult factory.

27. Shaft sleeve scored—remachine or replace as required.

28. Cavitation—increase NPSH available. Consult factory.

29. Pump capacity too low—consult factory for minimum

continuous flow.

30. Excessive vibration—See Section D.

31. Improper bearing lubrication or bearings worn out—inspect

and replace as required.

Problem

A. No liquid delivered,

not enough liquid

delivered, or not

enough pressure

1, 2, 3 ,4, 5, 6, 7, 8, 9,

10 11, 12, 13, 14, 18,

19, 20.

4, 5, 7, 8, 9, 11, 12, 20.

6, 13, 14, 15, 16, 21,

22, 23, 24, 31.

15, 16, 17, 28, 31.

8, 24, 25, 26, 27.

8, 24, 25, 26, 27.

15, 16, 17, 29, 30, 31.

B. Pump works a while

and then quits

C. Pump takes too much

power

D. Pump is noisy or

vibrates

E. Pump leaks

excessively at stuffing

box

F. High bearing

temperature

G. Stuffing box

overheating

Possible Causes

& Corrections