www.desatech.com

113109-01G 9

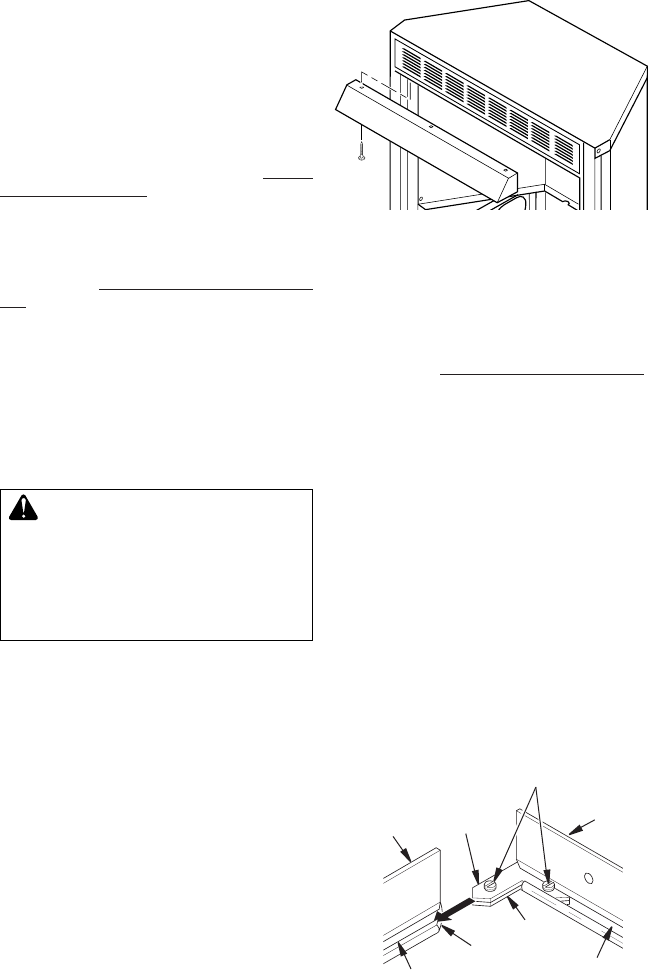

Figure 5 - Installing Hood to Firebox

Note: Your replace is designed to be used in

zero clearance installations. Wall or framing ma-

terial can be placed directly against any exterior

surface on the rear, sides or top of your replace,

except where standoff spacers are integrally at-

tached. If standoff spacers are attached to your

replace, these spacers can be placed directly

against wall or framing materials.

Use the dimensions shown for rough openings

to create the easiest installation. See Built-In

Fireplace Installation, page 12.

IMPORTANT: Vent-free heaters add moisture

to the air. Although this is benecial, installing

replace in rooms without enough ventilation

air may cause mildew to form from too much

moisture. See Air for Combustion and Ventila-

tion, page 6.

IMPORTANT: Make sure the replace is level.

If replace is not level, log set will not work

properly.

Use the correct gas type (natural or propane/

LP) for your replace. If your gas supply is not

correct, do not install replace. Call dealer

where you bought replace for proper type

replace.

-

This replace accepts a blower assembly with

an electrical cord. The electrical cord is ve feet

in length. You must locate replace within reach

of a 120 volt grounded electrical outlet. If not,

you must install an electrical outlet within reach

of replace power cord. The GA3555 outlet

accessory is used for built-in applications with

blower accessory installed.

INSTALLING HOOD

Install hood to top of rebox as shown in

Figure 5. Use 3 Phillips screws provided.

INSTALLATION

Continued

Figure 6 - Assembling Perimeter Trim

Side Trim

Top

Trim

Slot

Mitered

Edge

Slot

Shim

Set Screws

Adjusting

Plate

ASSEMBLING AND ATTACHING

OPTIONAL PERIMETER TRIM

IMPORTANT: If you are recessing the re-

box in a wall, do not attach perimeter trim at

this time. See Built-In Fireplace Installation,

page 12.

Note: The instructions below show assembling

and attaching perimeter trim to replace.

1. Remove packaging from three pieces of

perimeter trim.

2. Locate four perimeter screws, two adjust-

ing plates with set screws and two shims

in the hardware packet.

3. Align shim under adjusting plate as shown

in Figure 6.

4. Slide one end of adjusting plate/shim in

slot on mitered edge of top perimeter trim

(see Figure 6).

5. Slide other end of adjusting plate/shim in

slot on mitered edge of side perimeter trim

(see Figure 6).

6. While rmly holding edges of perimeter trim

together, tighten both set screws on the

adjusting plate with slotted screwdriver.