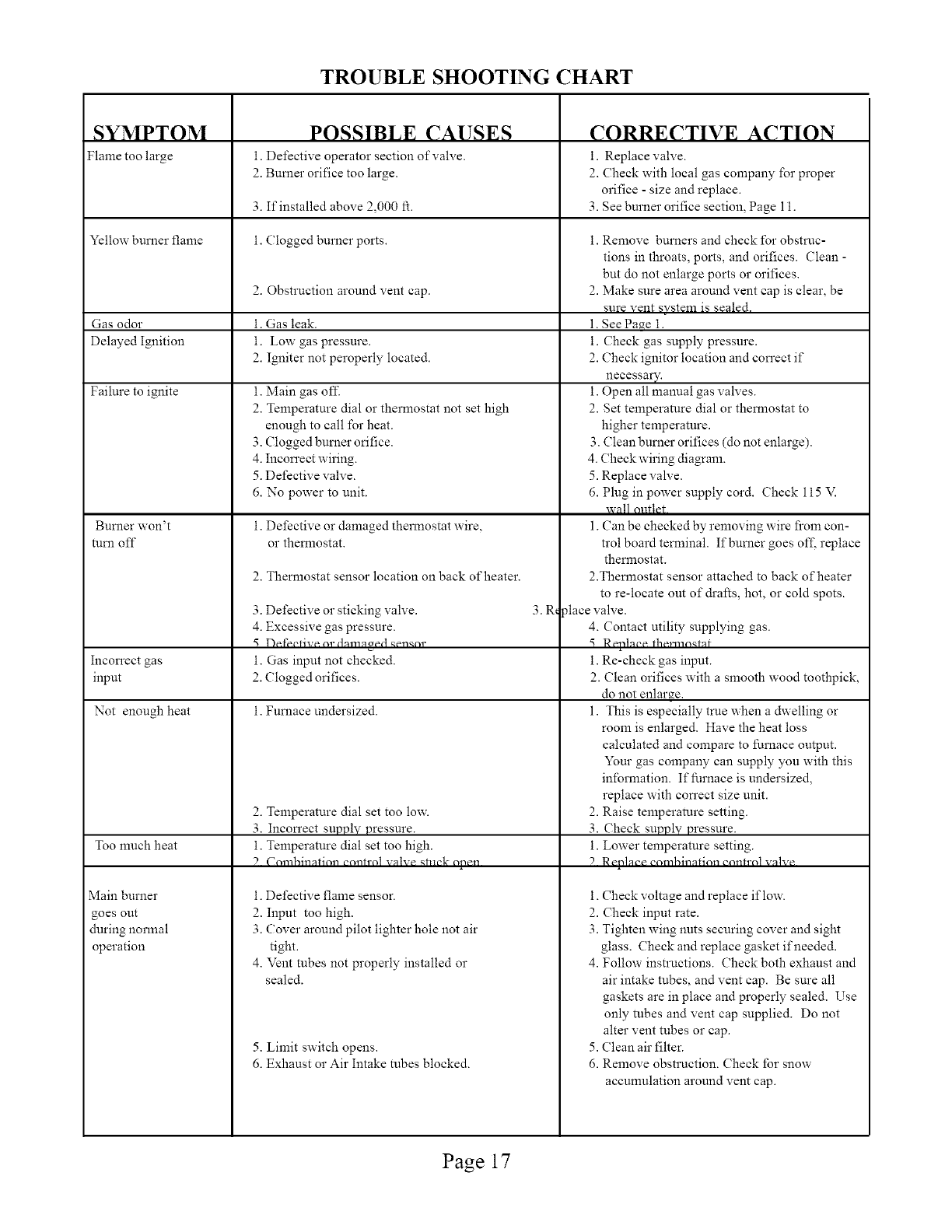

TROUBLE SHOOTING CHART

SYMPTOM

Flame too large

Yellow burner flame

Gas odor

Delayed Ignition

Failure to ignite

Burner won't

mm off

i.

2.

3.

i.

i.

I.

2.

3.

4.

5.

6.

3.

4.

i.

2.

Incon'ect gas

input

Not enough heat i.

Too much heat

Main burner

goes out

duringnormal

operation

2.

3.

I.

9

i.

2.

3.

POSSIBLE CAUSES CORRECTIVE ACTION

Defective operator section of valve, i. Replace valve.

Bumer orifice too large. 2. Check with local gas company for proper

orifice - size and replace.

If installed above 2,000 ft. 3. See burner orifice section, Page 11.

Clogged burner ports, i. Remove burners and check for obstruc-

tions in throats, ports, and orifices. Clean -

but do not enlarge ports or orifices.

Obstruction around vent cap. 2. Make sure area around vent cap is clear, be

sure vent svstem is sealed.

Gas leak. 1. See Pa_e 1.

Low gas pressure, i. Check gas supply pressure.

Igniter not peroperly located. 2. Check ignitor location and con'ect if

necessa_.

Main gas off. i. Open all manual gas valves.

Temperature dial or thermostat not set high 2. Set temperature dial or themmstat to

enough to call for heat. higher temperature.

Clogged burner orifice. 3. Clean burner orifices (do not enlarge).

Ineon'ect wiring. 4. Check wiring diagram.

Defective valve. 5. Replace valve.

No power to unit. 6. Plug in power supply cord. Check 115 V.

wall 0ml_r,

Defective or damaged thermostat wire, 1. Can be checked by removing wire from con-

or themlostat, trol board terminal. If burner goes oft', replace

thermostat.

Thermostat sensor location on back of heater. 2.Thermostat sensor attached to back of heater

to re-locate out of &afts, hot, or cold spots.

Defective or sticking valve. 3. R, _lace valve.

Excessive gas pressure. 4. Contact utility supplying gas.

Flefoetivenr_{nmnoecl vonanr q Renlm-e themanat_t

Gas input not checked, i. Re-check gas input.

(:logged orifices. 2. (;lean orifices with a smooth wood toothpick,

do not enlarge.

Furnace undersized. 1. This is especially true when a dwelling or

room is enlarged. Have the heat loss

calculated and compare to A_rnace output.

Your gas company can supply you with this

information. If furnace is undersized,

replace with con'ect size unit.

Temperature dial set too lox_: 2. Raise temperature setting.

Incon'ect supply pressure. 3. Check supply pressure.

Temperature dial set too high. i. Lower temperature setting.

(_nmhinatinn enntrnl valve _tuek nnen 9 Renlaee enmhinatinn enntrnl valve

Defective flame sensor, i. Check voltage and replace if low.

Input too high. 2. Check input rate.

Cover around pilot lighter hole not air 3. Tighten wing nuts securing cover and sight

tight.

Vent robes not properly installed or

sealed.

5. Limit switch opens.

6. Exhaust or Air Intake robes blocked.

glass. Check and replace gasket if needed.

4. Follow instructions. Check both exhaust and

air intake tubes, and vent cap. Be sure all

gaskets are in place and properly sealed. Use

only mbes and vent cap supplied. Do not

alter vent tubes or cap.

5. Clean air filter.

6. Remove obstruction. Check for snow

accumulation around vent cap.

Page 17