6

W415-0298 / K / 12.06.07

Proceed once the vent installation is complete.

NOTE: All gas connections must be contained within

the fi replace when complete.

1. Move the fi replace into position and secure to the fl oor

through the 1/4" holes located at either side of the base.

2. The fi replace is designed to accept 3/8" gas supply line.

The fi replace is equipped with a 3/8" manual shut-off valve.

3. Connect the gas supply in accordance to local codes.

In the absence thereof, install according to the National

Installation Code.

4. When fl exing any gas line, support the gas valve so

that the lines are not bent or kinked.

5. Check for gas leaks by brushing on a soap and water

solution.

DO NOT USE OPEN FLAME.

Unusually tight construction is defined as con-

struction where:

a) Walls and ceilings exposed to the outside atmosphere

have a continuous water vapour retarder with a rating of

1 perm (6 x 10

-11

kg per pa-sec-m

2

) or less with openings

gasketed or sealed, and

b) Weather stripping has been added on openable win-

dows and doors, and

c) Caulking or sealants are applied to areas such as

joints around window and door frames, between sole plates

and fl oors, between wall-ceiling joints, between wall panels,

at penetrations for plumbing, electrical, and gas lines, and

at other openings.

An unvented room heater is recommended for use as a

secondary heat source rather than as a primary source.

Gas combustion produces water vapour which could occur

at the rate of approximately one ounce of water for every

1,000 BTU/hr of gas input. During the cold weather season,

indoor humidity levels tend to be low. Consequently, this

water vapour can enhance the living space. However if a

problem should occur:

a) ensure suffi cient combustion and circulation air

b) use a dehumidifi er

c) do not use the unvented room heater as a primary

heat source

Without suffi cient fresh air for proper operation, poor fuel

combustion can result. Carbon Monoxide is a result of poor

combustion.

If additional fresh air is required, use one of the meth-

ods described in the National Fuel Gas Code, ANSI Z223.1,

Section 5.3 or the applicable local code.

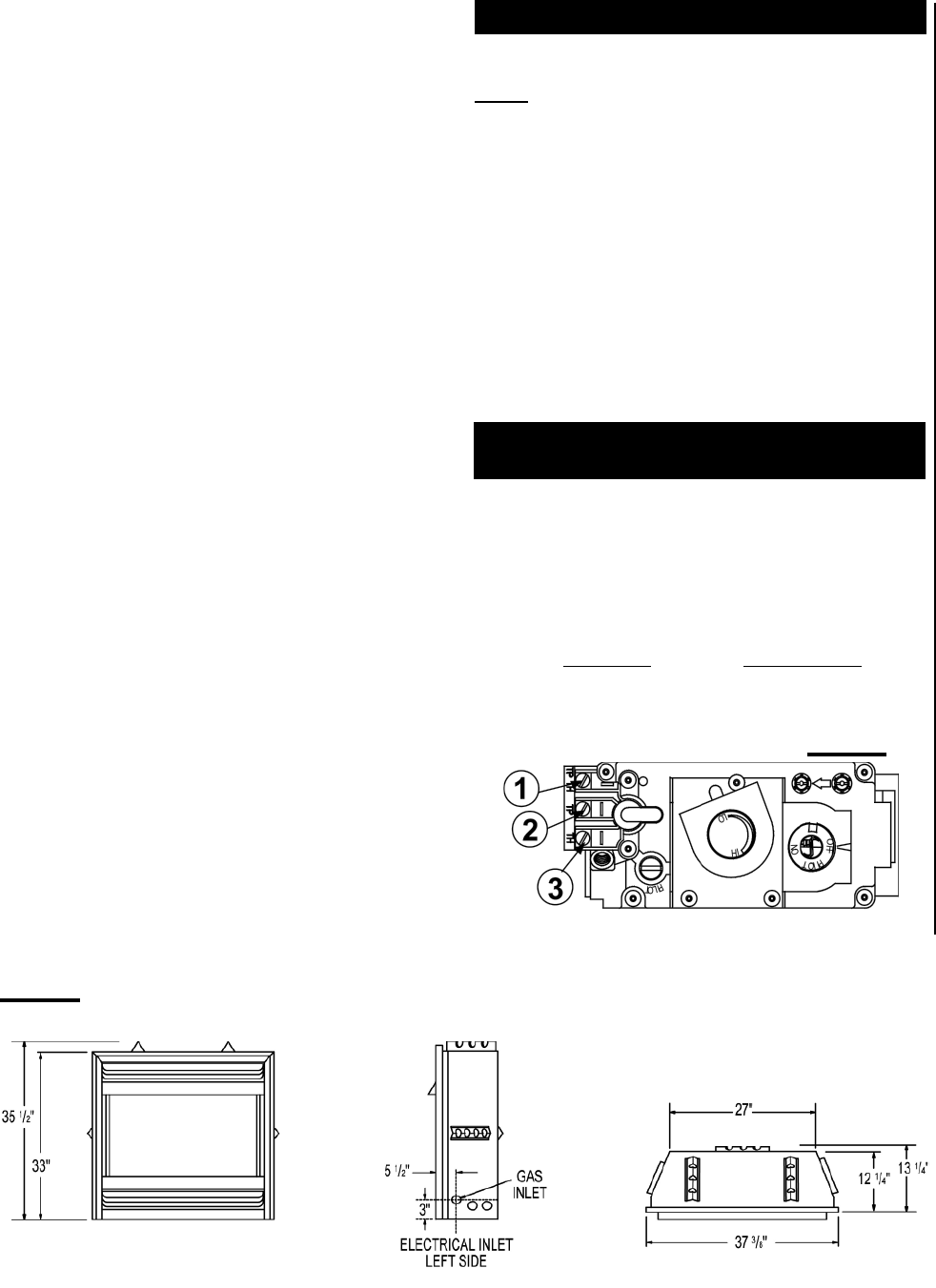

GAS INSTALLATION

FIGURE 3

For ease of accessibility, an optional remote wall switch may

be installed in a convenient location. A 20’ length of millivolt

wire is connected to the gas valve for the wall switch. How-

ever if a greater length is required route 2-strand (solid core)

millivolt wire through the electrical hole located at the bottom

left side of the unit. The recommended maximum lead length

depends on wire size:

WIRE SIZE MAX. LENGTH

14 gauge 100 feet

16 gauge 60 feet

18 gauge 40 feet

OPTIONAL WALL SWITCH

INSTALLATION

FIGURE 2