18

Aspen Woodburning Stove

30000369

In newer homes that are well-insulated and weather-

tight, poor draft may result from insufficient air in the

house. In such cases, a slightly opened window or

door, near the stove on the windward side of the house

will provide the fresh air needed.

A more effective option for delivering ample combustion

air to the stove is to duct air directly from outdoors to

the stove. In fact, in some areas, provisions for outside

combustion air are required in all new construction. The

optional Aspen Outside Air Adapter #1897 is available

from your dealer.

When you first begin using the stove, pay attention

to the air control settings. You will quickly find that a

specific setting will give you a fixed amount of heat. It

may take some time to determine the amount of heat

and the length of burn you should expect from various

settings.

Do not for any reason attempt to increase the firing

of your heater by altering the air control adjustment

range outlined in these directions.

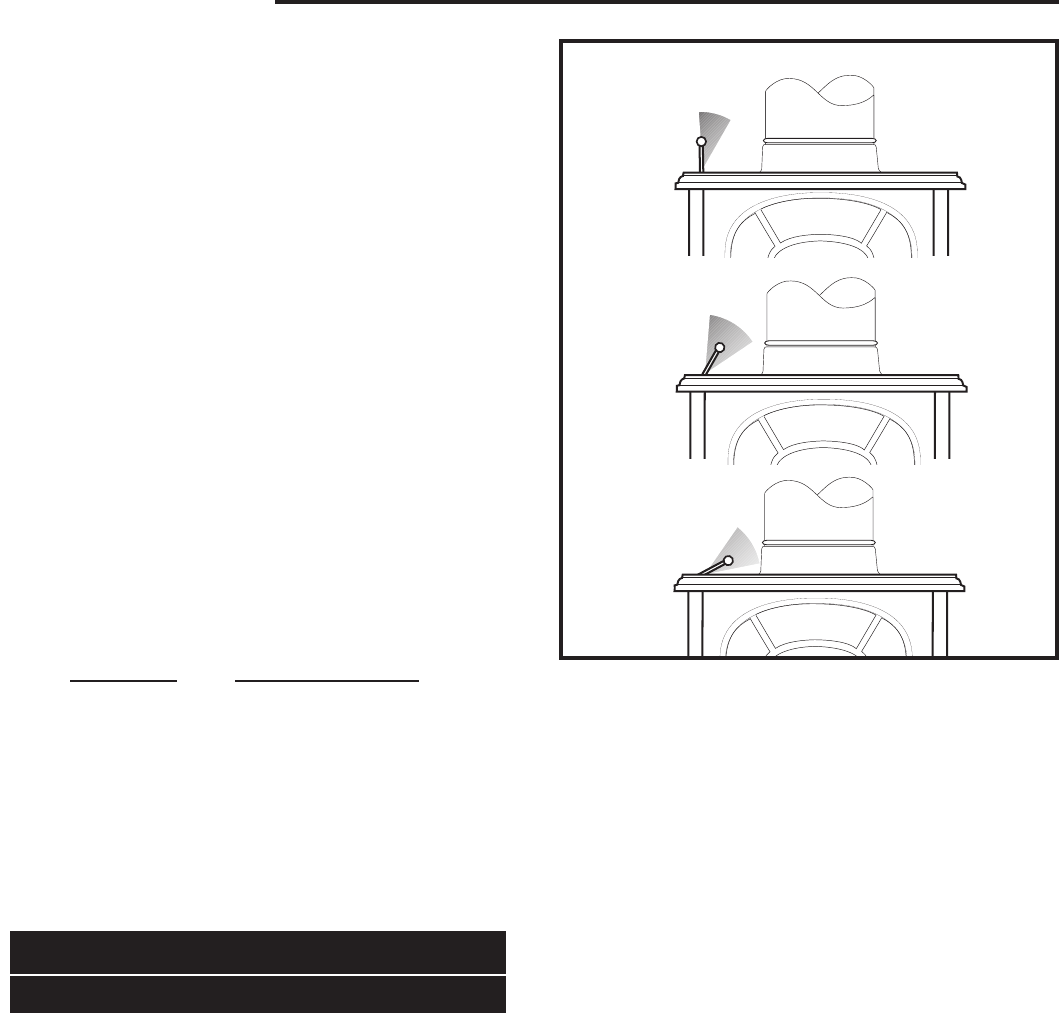

Use the following air control settings as a starting point

to help determine the best settings for your installation.

(Fig. 28)

Aspen Control Settings

Burn Rate Primary Air Control

High From 12:00

Medium From 1:00

Low From 2:00

Before you start using the stove, please read the Ap-

pendix on Draft Management starting on page 24 to

learn how the characteristics of your installation will

affect the stove’s performance. You and the stove are

parts of a system, and other parts of the system have a

strong effect on operation; you may need to vary your

firing technique to get the performance you want.

Starting and Maintaining a Fire

Conditioning Your Stove

Cast iron is extremely strong, but it can be broken with

a sharp blow from a hammer or from the thermal shock

of rapid and extreme temperature change.

The cast plates expand and contract with changes in

temperature. When you first begin using your Aspen,

minimize thermal stress by allowing the plates to adjust

gradually during three or four initial break-in fires follow-

ing Steps 1-3.

BURN SOLID WOOD FUEL ONLY, AND BURN IT

DIRECTLY ON THE GRATE. DO NOT ELEVATE THE

FUEL. DO NOT BURN COAL OR OTHER FUELS.

WARNING: OPERATE THIS STOVE ONLY WITH THE

DOOR FULLY CLOSED.

High

ST262

air inlet settings

12/15/99 djt

Medium

Low

ST262a

Fig. 28 Air inlet shutter settings; Low - Medium - High.

The Primary Air Inlet must be fully open when start-

ing a fire or when refueling.

Step 1. Open the primary air control fully.

Step 2. Place several sheets of crumpled newspaper

in the stove. Avoid using glossy or colored paper, as

these burn poorly. At the front of the firebox, place

on the paper six or eight pieces of dry kindling split

to a finger-width size, and on the kindling lay two or

three larger sticks of split dry wood approximately

1-2” (25-51 mm) in diameter.

Step 3. Light the newspaper and close the door.

Gradually build up the fire by adding a few 3-5” (80-

120 mm) diameter splits. If this is one of the first

few “break-in” fires, let the fire burn brightly, and

then let it die out.

• During the break-in fires, don’t let the stove get

hotter than 500°F. (260°C) as measured on an op

-

tional stove-top thermometer. Adjust the air control

lever as necessary to control the fire.

• Some odor from the stove’s hot metal, the paint,

and the cement is normal for the first few fires.

NOTE: Some chimneys need to be “primed,” or

warmed up, before they will draw sufficiently to sus-

tain a fire. To correct this situation, roll up a couple

pieces of newspaper, place them on top of the

kindling and toward the back of the stove, light them,

and close the door. This should heat the chimney

enough to initiate strong draft.