42

DV360/580 Series Direct Vent Gas Fireplace

20010667

unfastening the screw on the tray to the right side of

the orifice. Slide the bracket/gasket assembly over

the fitting on the manifold toward the back with the

gasket to the right. Secure the bracket/gasket as-

sembly using the screw removed earlier. (Fig. 67a)

5. Replace the orifices according to the table on Page

42.

6. Replace the mixing tube on the burner housing by

removing the two (2) screws that secure the mixing

tube to the burner housing assembly. Remove the

old gasket behind the mixing tube. (Fig. 68) NOTE:

The mixing tube for propane gas has only two

bimetallic springs that are in the closed position

at cold start. The mixing tube for natural gas has

two spring/shutter collar assemblies that are in

the closed position at cold start. Make sure the

correct mixing tube is used for conversion.

7. Use the new gasket supplied in the conversion kit

and proper mixing tube and replace in reverse order.

8. Reassemble the burner housing assembly, the

burner tube assembly and the fettle in reverse order.

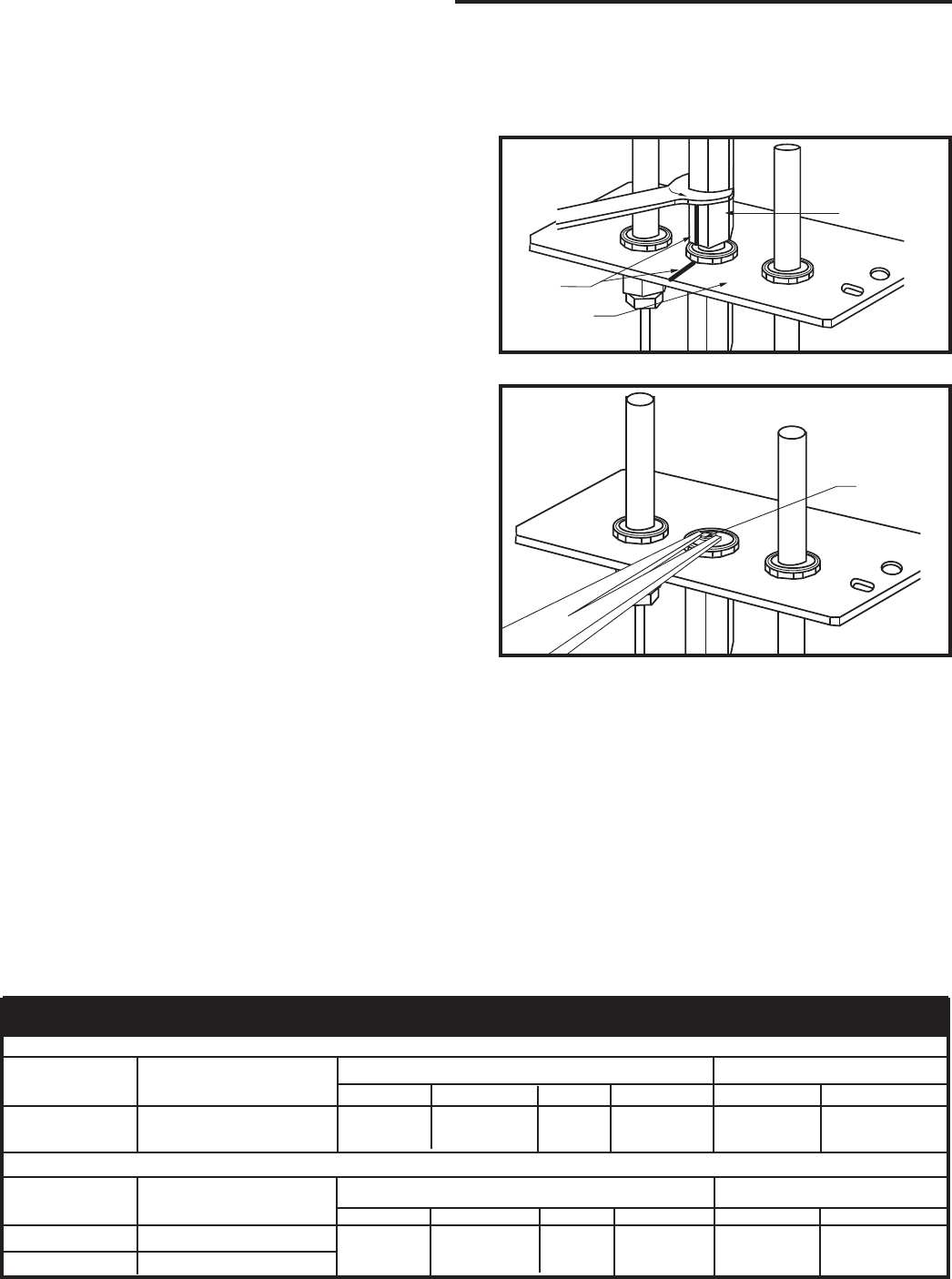

DV580

1. Remove manifold mounting screw from burner. (Fig.

69)

2. Remove burner orifice from manifold assembly using

3/8” wrench. (Fig. 70)

3. Install conversion orifices in place of orifices just

removed.

4. Remove air shutters from burner pan by removing

shutter retaining screw then air shutter. (Fig. 71)

5. Replace only the rear air shutters.

Natural Gas: Rear air shutter, fully open.

Front air shutter, fully open.

LP: Rear air shutter, fully open.

Front air shutter, fully open.

6. Re-install manifold to burner pan.

Conversion to Natural Gas

Burner Orifice Input (BTU/hr)

Kit # Model Front Part # Rear Part # Minimum Maximum

20010751 DV360RP/RFP #53 20007347 #43 30000512 18,500 30,000

(.0595”) (.089”)

Conversion to LP

Burner Orifice Input (BTU/hr)

Kit # Model Front Part # Rear Part # Minimum Maximum

20010752 DV360RN/RFN #64 20010935 #54 20000130 17,000 30,000

20011025 DV360EN (.036”) (.055”)

Table 1 Injector Orifice Size Matrix

2. Remove pilot orifice with needlenose pliers. (Fig. 77)

3. Install conversion pilot orifice.

4. Reinstall pilot hood. Be sure to align pilot hood with

index marks.

CO105

Gas Conversion

Pilot

2/15/99 djt

Index

Marks

Pilot

Bracket

Pilot Hood

CO105

Fig. 76 Remove pilot hood.

CO106

Gas Conversion

Pilot2

2/15/99 djt

Pilot

Orifice

CO106

Fig. 77 Remove pilot orifice.

5. Turn the gas supply valve and gas valve on and test

for leaks. Use a 50/50 solution of liquid soap and

water to test for leaks at gas fittings and joints. Apply

water/soap solution with brush only - do not over ap-

ply. NEVER test with an open flame.

6. Follow procedure on rating plate to light the pilot.

Check for leaks.

7. Turn main burner on and check for leaks.

8. Install logs. Refer to Page 25 for proper log place-

ment.

Installation complete.

Pilot Orifice Conversion

NOTE: It is not necessary to remove the pilot tube for

conversion.

1. Loosen pilot hood turning counterclockwise using a

7/16” wrench. (Fig. 76)