30

Intrepid II Woodburning Stove

2000966

6. Remove the damper housing. It is held in place by

two weld screws and two chrome acorn nuts in the

back of the stove. Loosen the chrome acorn nuts

and rotate the tabs to release the damper housing.

You may find it necessary to remove or loosen the

thermostat cover to access the one of acorn nuts

installed behind the cover.

7. Remove the rear airtube in the back of the stove

which is held in place with two phillips screws.

8. Take out the secondary probe by removing the upper

phillips screw and sliding the probe out of the hole.

9. Lift the damaged refractory chamber up and out of

the firebox.

10. Reverse the procedure for installing the new refrac-

tory chamber.

Replace the Stove Gaskets as Needed

The Intrepid uses fiberglass rope gaskets to make a

tight seal between some parts. With use, particularly on

those parts that move, gaskets can become brittle and

compressed, and can begin to lose their effectiveness.

These will need periodic replacement.

The sizes of replaceable gasket are listed below, along

with their applications.

Gasket Diameter ... And the Parts it Seals

5/16” wire gasket The griddle to the stove top

5/16” The damper to the upper fire

back; the front doors to the

stove front; and the door

halves to each other

There is a flat, die-cut gasket between each glass panel

and its door. See page 24 for information on replacing

the glass panel or its gasket.

If you need to change a gasket, first obtain an appropri

-

ate replacement from your Vermont Castings, Dealer.

Wait until the fire is out and the stove has cooled. Be

sure to follow the standard safety procedure for working

with dusty materials: Wear safety goggles and a dust

mask.

The procedure for replacing the gaskets is the same,

regardless of the gasket location.

1. Remove the existing gasket by grasping an end and

pulling firmly.

2. Use a wire brush or a screwdriver to clean the chan

-

nel of any remaining cement or bits of gasket. Re-

move stubborn deposits of cement with a cold chisel

if necessary.

3. Determine the correct length of the appropriate-sized

gasket by laying it out in the channel. Allow an extra

1-2” (25-50mm) and mark the spot to be cut.

4. Remove the gasket from the channel, place it on a

wood cutting surface, and cut it at the marked spot

with a utility knife. Twist the ends slightly to keep the

gasket from unraveling.

INTREPID II

ST533

remove catalyst

11/00

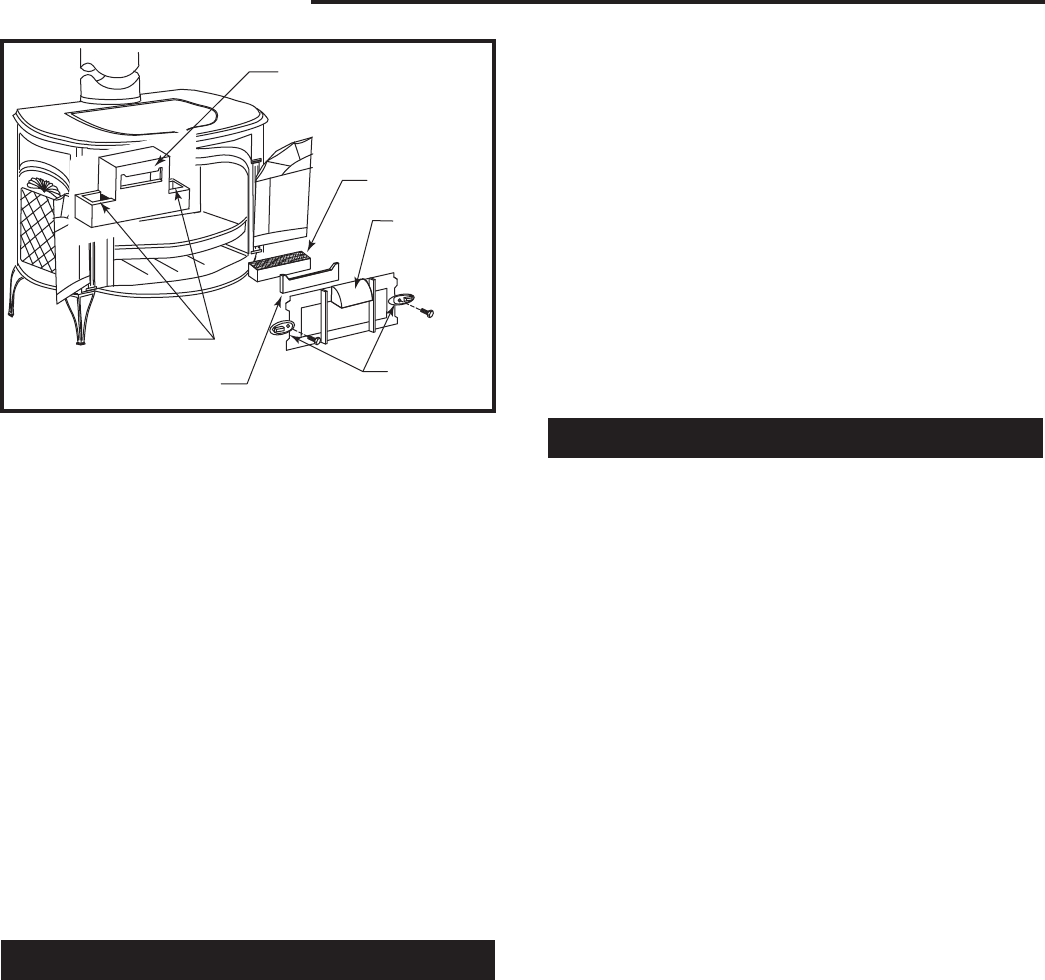

Refractory Chamber

Refractory Access Panel

Upper

Fireback

with Throat

Hood

Catalytic Block

Exhaust

Pockets

Clamps

ST533

Fig. 46 Removing the catalytic element.

9. Use a flashlight and a mirror, inserted into one of

the exhaust pockets of the refractory chamber, to in-

spect the probe. The end of the probe should extend

about 1” into the combustion chamber, and should

not show any signs of deterioration.

Use the stove in your usual manner for two weeks,

inspecting the chimney and the chimney connector

frequently.

If creosote does not build up as quickly as before, it is

likely that the performance change was caused by fly

ash deposits on the catalytic element. However, moni-

tor the chimney system for a few weeks to ensure that

proper performance continues.

If you continue to find a significant creosote buildup or if

you continue to see excessive smoke from the chimney,

the catalytic element will need to be replaced. Call your

dealer for information about a replacement.

NOTE: Use only replacement catalyst, part no. 160-

2521.

Replace Refractory Package

Refer to Figure 46.

1. Remove andirons.

2. Reach inside the stove with pair of pliers and turn

the two clamps that hold the fireback 90°. Turn the

let clamp clockwise and the right clamp counter-

clockwise. The bolts that hold these clamps are

tapped into the back as well as capped by chrome

acorn nuts in the back.

3. Grasp the upper fireback by its vertical ribs and re

-

move it, together with the attached throat hood. Pull

the left side out first.

4. Carefully remove the refractory access panel in front

of the catalytic block.

5. Gently slide the catalytic block out of the refractory

chamber.