23

Intrepid II Woodburning Stove

2000966

produce soot or large flakes of char or fly ash that can

coat the combustor and cause smoke to spill into the

room. Coal smoke also can poison the catalyst so that it

won’t operate properly.

In general, the fire must be sufficiently well-established

to ensure catalytic activity is initiated. When first starting

a fire, maintain a medium- to high- firing rate for at least

twenty minutes. This ensures the stove, catalyst, and

fuel are all stabilized at the proper operating tempera-

tures. This may be long enough to warm the chimney

well enough to support a good draft; some installations

may need more time. Please read the Draft Manage-

ment information starting on Page 25 to see if your

installation has features that may require more time to

warm up.

Even though it is possible for the fire to get quite hot

within a few minutes, the combustor may stop working

or the fire may go out if the fire is allowed to die down

immediately as a result of closing the damper. Once the

combustor starts working, heat generated by burning

the smoke will keep it working.

To determine whether the combustor is operating, ob

-

serve the amount of smoke leaving the chimney when

the damper is activated and when it is not. This proce-

dure is described on Page 29.

Conditioning Your Stove

Cast iron is extremely strong, but it can be broken with

a sharp blow from a hammer or from the thermal shock

of rapid and extreme temperature change.

The cast plates expand and contract with changes in

temperature. When you first begin using your Intrepid II,

minimize thermal stress by allowing the plates to adjust

gradually during three or four initial break-in fires follow-

ing Steps 1-3 below.

Starting and Maintaining a Wood Fire

Burn solid wood fuel only in the Intrepid II, and burn it

directly on the grate. Do not elevate the fuel. Do not

burn coal or other fuels.

The damper must be open when starting a fire or

when refueling.

1. Open the stove damper, and open the primary air

control fully.

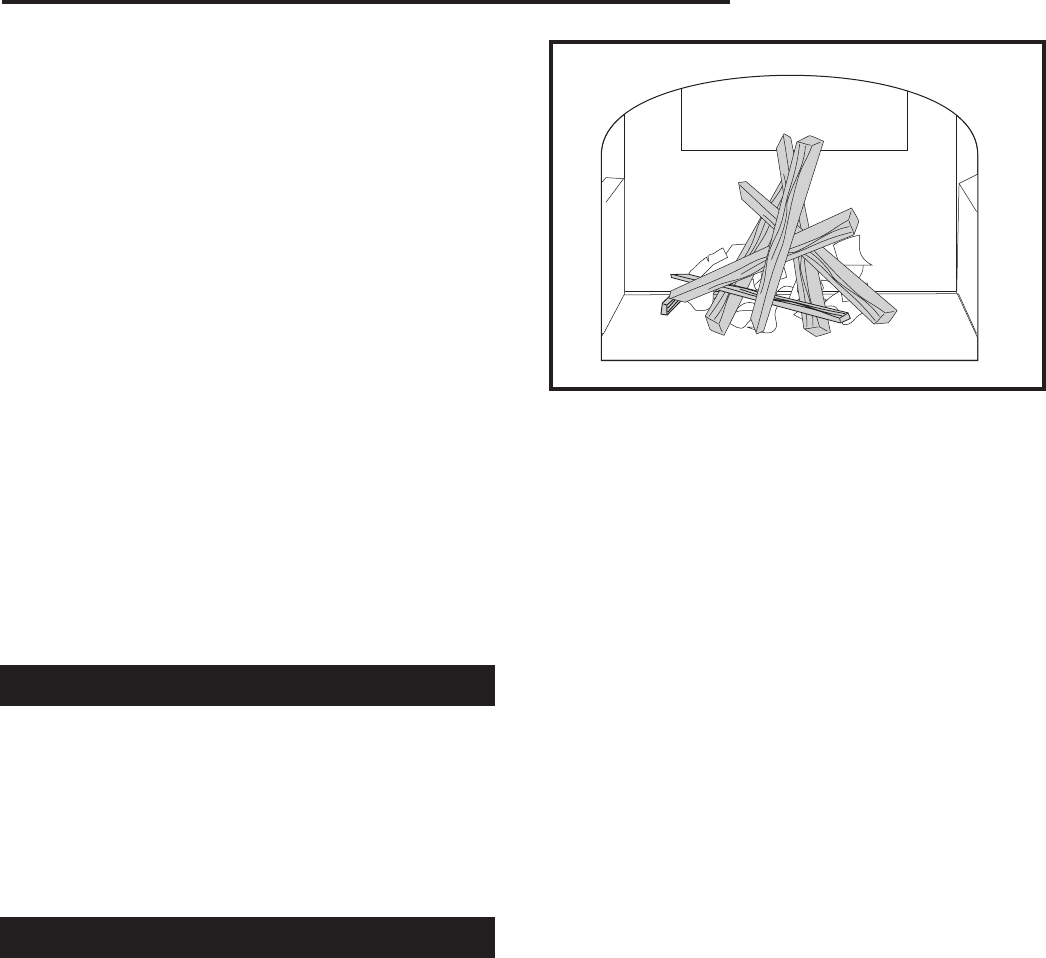

2. Place several sheets of crumpled newspaper in the

stove. Do NOT use glossy advertisements or colored

paper, as they can poison the catalyst. Place on the

paper six or eight pieces of dry kindling split to a

finger-width size, and on the kindling lay two or three

larger sticks of split dry wood approximately 1-2”

(25-50mm) in diameter. (Fig. 39)

ST263

starting a fire

12/99

ST263

Fig. 39 Start the fire with newspaper and dry kindling.

DO NOT USE CHEMICALS OR FLUIDS TO START

THE FIRE. DO NOT BURN GARBAGE OR FLAMMA-

BLE FLUIDS SUCH AS GASOLINE, NAPHTHA, OR

ENGINE OIL. Also, never use gasoline-type lantern

fuel, kerosene, charcoal lighter fluid, or similar

liquids to start or “freshen up” a fire. Keep all such

liquids well away from the Intrepid II while it is in

use.

3. Light the newspaper and close the door. Gradu

-

ally build up the fire by adding a few 3-5” (76-127

mm) diameter splits. If this is one of the first few

“break-in” fires, let the fire burn brightly, and

then let it die out.

During the break-in fires, don’t let the stove get hotter

than 500°F (260°C) as measured on an optional stove-

top thermometer. Adjust the air control lever as neces-

sary to control the fire. Some odor from the stove’s hot

metal, the paint, and the cement is normal for the first

few fires.

NOTE: Some chimneys need to be “primed,” or

warmed up, before they will draw sufficiently to start

a fire. To correct this situation, roll up a couple pieces

of newspaper, place them on top of the kindling and

toward the back of the stove, light them, and close the

doors. This should heat the chimney enough to initiate

a draft.

Once the draft is established, open the front door and

light the rest of the fuel from the bottom. Do not light the

main bed of fuel until the chimney begins drawing, and

repeat the procedure as often as necessary if the initial

attempt is unsuccessful.

4. If your Intrepid II has been broken-in previously

using Steps 1-3, continue to build the fire gradually.

Add larger wood with a diameter of 3-4” (76-102

mm). (Fig. 40)