9

UNIT DAMAGE HAZARD

Failure to follow this caution may result in furnace

component damage.

DO NOT use wire brush or other sharp object to inspect or

dislodge materials in secondary heat exchangers as cutting

of the secondary heat exchanger protective coating may

occur. Flush with water only.

CAUTION

!

8. Flush inside of collector box with water until discharge

from condensate trap is clean and runs freely.

9. Inspect inside area of collector box for any pieces of

foreign materials and remove them if present.

10. Reassemble inducer assembly by reversing items 5--7.

Tighten the vent coupling clamp screw(s) to 15 in.--lb of

torque.

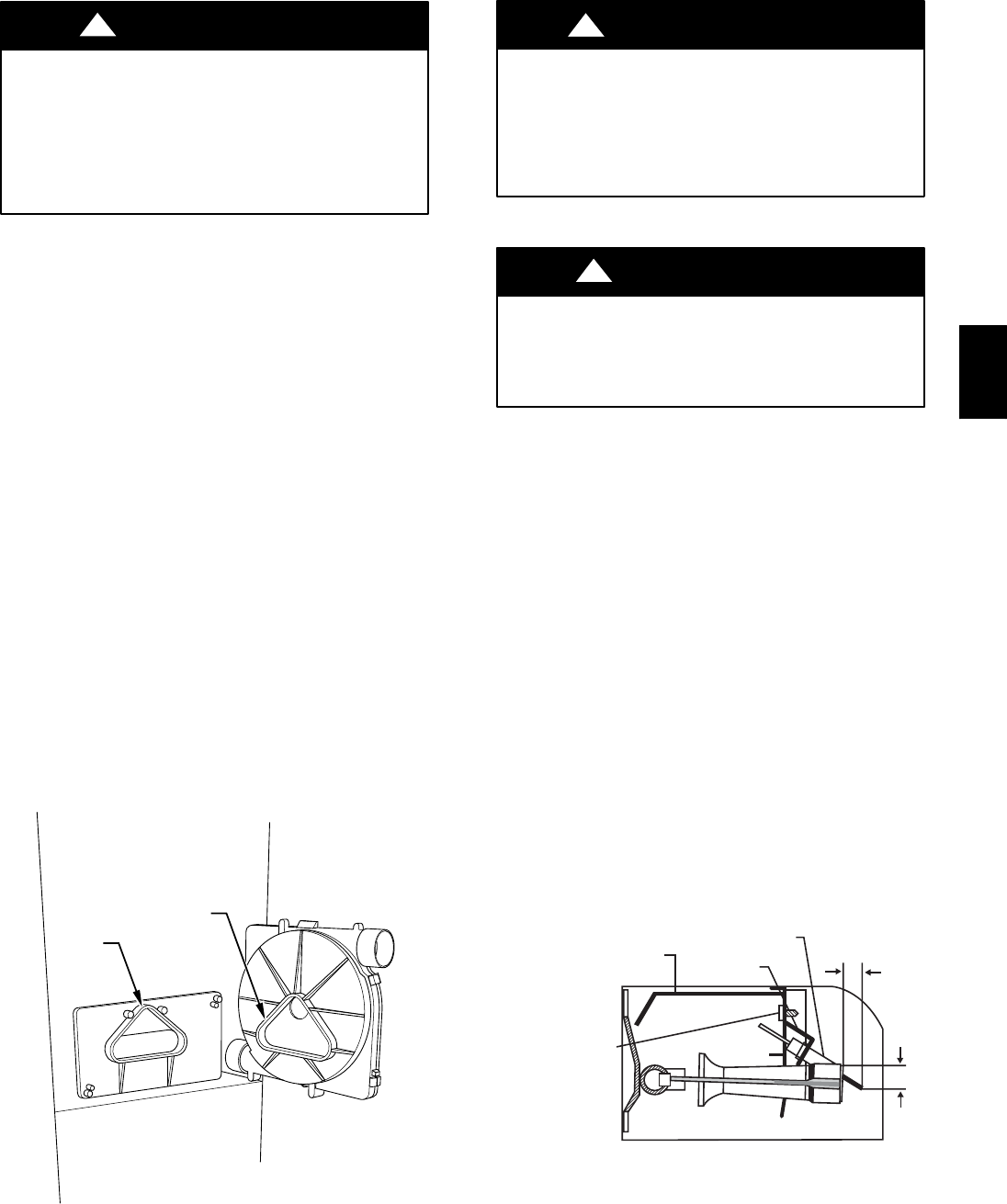

NOTE: If seal between the inducer housing and the collector

box is damaged in any way, it must be repaired. To repair, apply

sealant releasing agent such as PAM cooking spray or equivalent

(must not contain corn nor canola oil, halogenated hydrocarbons

nor aromatic content, to prevent inadequate seal from occurring)

to inducer housing. (See Fig. 12.) Apply a small bead of G.E.

RTV 162, G.E. RTV 6702, or Dow -- Corning RTV 738 sealant to

groove in collector box.

11. Refer to furnace wiring diagram and reconnect wires to

inducer motor and pressure switches or connectors.

12. Reconnect pressure tubes to pressure switches. See

diagram on main furnace door for proper location of tubes.

Be sure tubes are not kinked. (See Fig. 10.)

13. Turn on gas and electrical supplies to furnace.

14. Check furnace operation through two complete heat

operating cycles. Check area below inducer housing, vent

pipe, and condensate trap to ensure no condensate leaks

occur. If leaks are found, correct the problem.

15. Check for gas leaks.

16. Replace main furnace door.

RTV

PAM

A93081

Fig. 12 -- Gasket on Collector Box

FIRE AND EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury , death o r property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made s pecifically for

the d etection of leaks to check all connections.

!

WARNING

G. SERVICING HOT SURFACE IGNITER

BURN HAZARD

Failure to follow t his caution may result in personal injury.

Allow igniter to cool before removal. Normal operating

temperatures exceed 2000_.

CAUTION

!

The igniter does NOT require annual inspection. Check igniter

resistance before removal.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect igniter wire connection.

4. Check igniter resistance. Igniter resistance is affected by

temperature. Only check resistance when the i gniter is at

room temperature.

a. Using an ohm meter, check resistance across both igniter

leads in connector .

b. Cold reading should be between 40 ohms and 70 ohms.

5. Remove igniter assembly.

a. Remove burner box cover.

b. Remove igniter wires from slot i n manifold grommet.

(See Fig. 7.)

c. Using a 1/4-- in. driver, remove the single screw securing

theigniterbrackettotheburnerboxbracket(SeeFig.13.)

and carefully withdraw the igniter and bracket assembly

through the front of the burner box without striking the

igniteron surrounding parts.Notethatthe igniterbracket

has a handle that extends to the front of the burner box

to aid in handling. (See Fig. 13.)

d. Inspect igniter for signs of damage or failure.

BRACKET

IGNITER

9/16˝

11/16˝

EXTENDED IGNITER

BRACKET HANDLE

IGNITER BRACKET

MOUNTING SCREW

A05075

Fig. 13 -- Igniter Bracket

58MVC