27

AIR COIL — To obtain maximum performance, clean the air

coil before starting the unit. A ten percent solution of dish-

washer detergent and water is recommended for both sides of

the coil. Rinse thoroughly with water.

PSC (Permanent Split Capacitor) Blower

Speed Selection —

All water source heat pumps are

factory set to deliver rated airflow at nominal static (0.15 in.

wg) on medium speed. Where higher static is needed, high

speed can be utilized (0.4 to 0.5 in. wg). Low speed will

deliver approximately 85% of rated airflow (0.10 in. wg). The

PSC blower fan speed can be changed on all units by swapping

wires connected to the relay contacts that control the fan. See

Fig. 27.

FOR 50RHR,RVR,RHS,RVS AND RDS UNITS — On the

control, the black wire is connected to High, blue wire is

connected to Medium and red wire is connected to Low. See

Fig. 19-22.

NOTE: Available airflows for all units are shown in Tables 8-13.

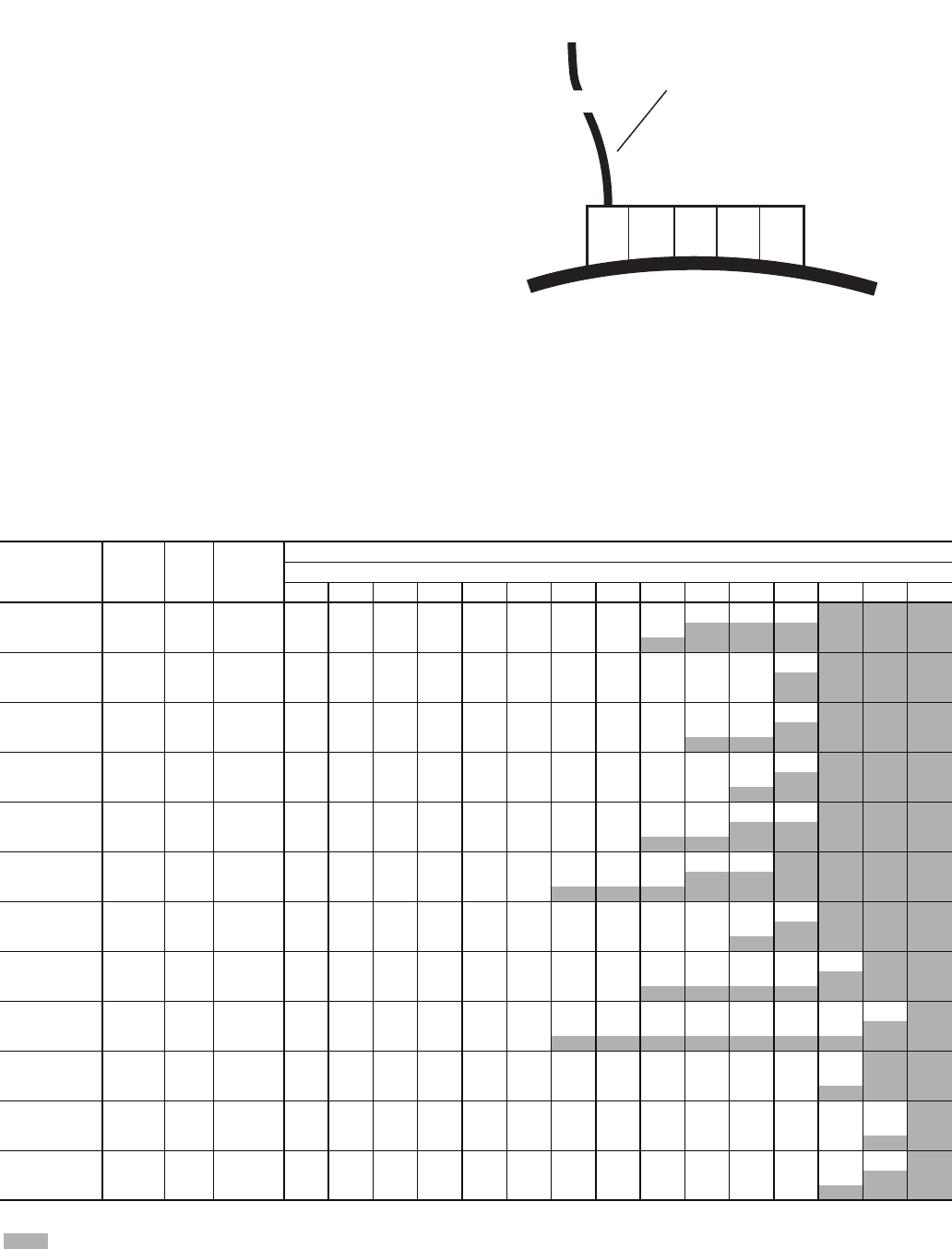

FOR 50RHC,RVC UNITS — The PSC blower fan speed

can be changed by moving the blue wire on the fan motor ter-

minal block to the desired speed as shown in Fig. 27. The

50RHC,RVC units are designed to deliver rated airflow at

nominal static (0.15 in. wg) on medium speed (factory setting)

and rated airflow at a higher static (0.4 to 0.5 in. wg) on high

speed for applications where higher static is required. Low

speed will deliver approximately 85% of rated airflow at

0.10 in. wg. An optional ‘High Static’ blower is available by

using the special option code in the model nomenclature.

Table 8 — 50RHR,RVR Blower Performance

LEGEND

*Size 006 available in 50RHR units only.

NOTES:

1. Units factory shipped on medium speed. Other speeds require

field selection.

2. All airflow is rated on 208 v operating with wet coil and clean air

filter.

3. All units ARI/ISO/ASHRAE 13256-1 rated on high fan speed.

4. Only two-speed fan (H & M) available on 575-v units.

50RHR,RVR

UNITS

RATED

CFM

MIN

CFM

FAN

SPEED

AIRFLOW (Cfm)

External Static Pressure (in. wg)

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.60 0.70 0.80 0.90

006* 200 150

HI 300 290 280 270 260 250 240 230 210 190 160 110

MED 240 230 220 210 200 190 180 160 140 130 110

LO 220 210 200 200 190 180 160 150 130 130

009 300 225

HI 450 440 430 420 400 390 370 350 320 310 300 230

MED 410 400 390 380 360 350 340 330 310 290 270

LO 370 360 350 340 320 320 310 300 280 260 240

012 375 300

HI 470 460 450 440 430 420 400 390 380 370 350 330 290

MED 410 400 380 370 360 360 350 340 330 320 310 290

LO 340 330 320 320 310 310 300 300 290 290

015 500 375

HI 750 730 710 700 680 660 630 600 570 540 500 400

MED 660 640 620 610 590 570 550 530 500 470 440 370

LO 580 570 550 540 520 500 480 460 430 400 370

019 600 450

HI 850 820 790 770 740 710 670 640 600 560 520 450

MED 700 680 660 640 620 590 560 530 500 470 440

LO 600 580 560 540 510 490 460 460

024 800 600

HI 980 950 920 890 860 830 790 760 720 680 640 540

MED 850 830 800 770 740 720 690 660 620 580 540 460

LO 700 680 660 650 630 610 590 560 530 500 470

030 1000 750

HI 1330 1300 1260 1230 1190 1150 1100 1050 1000 960 920 830

MED 1210 1190 1160 1130 1100 1050 1000 970 930 880 830 720

LO 1050 1030 1010 980 950 920 890 850 810 770 730

036 1200 900

HI 1580 1540 1500 1470 1440 1410 1370 1330 1280 1240 1200 1090 940

MED 1400 1370 1340 1310 1280 1250 1220 1190 1150 1100 1050 920

LO 1100 1080 1060 1040 1010 980 950 920 890 890

042 1400 1050

HI 1790 1760 1730 1700 1660 1630 1590 1550 1510 1480 1440 1370 1270 1120

MED 1500 1490 1470 1450 1420 1400 1380 1350 1320 1300 1270 1180 1070

LO 1110 1100 1090 1080 1060 1050 1040

048 1600 1200

HI 1910 1880 1840 1800 1750 1730 1700 1650 1600 1540 1480 1380 1300

1180

MED 1830 1790 1740 1700 1660 1620 1570 1540 1500 1450 1400 1320 1210 1120

LO 1700 1670 1640 1600 1560 1530 1490 1460 1430 1390 1340 1250 1170

High Static

048

1600 1200

HI 2180 2140 2090 2060 2030 1990 1940 1870 1800 1750 1690 1580 1440 1270

990

MED 2080 2050 2020 1970 1920 1870 1820 1740 1650 1640 1620 1530 1320 1220

910

LO 1990 1950 1910 1880 1840 1810 1770 1710 1650 1620 1580 1460 1340

1180

060 2000 1500

HI 2230 2220 2200 2160 2120 2090 2060 2040 2010 1990 1960 1880 1790 1660

MED 2040 2020 1990 1970 1940 1920 1890 1860 1830 1810 1780 1710 1620

LO 1840 1830 1810 1800 1780 1760 1730 1700 1670 1640 1600 1510

Shaded areas are below minimum CFM. This data is

provided for troubleshooting information only.

CFM — Cubic Feet Per Minute

CONNECT THE BLUE WIRE TO:

FAN MOTOR

MEDIUM FACTORY SETTING

H FOR HIGH SPEED FAN

M FOR MEDIUM SPEED FAN

L FOR LOW SPEED FAN

H

M

L

BLU

Fig. 27 — 50RHC,RVC Blower Speed Selection