14

Step 3 — Unit Location — The following guidelines

should be considered when choosing a location for a WSHP:

• Units are for indoor use only.

• Locate in areas where ambient temperatures are between

40 F and 100 F and relative humidity is no greater than

75%.

• Provide sufficient space for water, electrical and duct

connections.

• Locate unit in an area that allows easy access and

removal of filter and access panels.

• Allow enough space for service personnel to perform

maintenance.

• Return air must be able to freely enter the space if unit

needs to be installed in a confined area such as a closet.

NOTE: Correct placement of the horizontal unit can play an

important part in minimizing sound problems. Since duct-

work is normally applied to these units, the unit can be

placed so that the principal sound emission is outside the oc-

cupied space in sound-critical applications. A fire damper

may be required by the local code if a fire wall is penetrated.

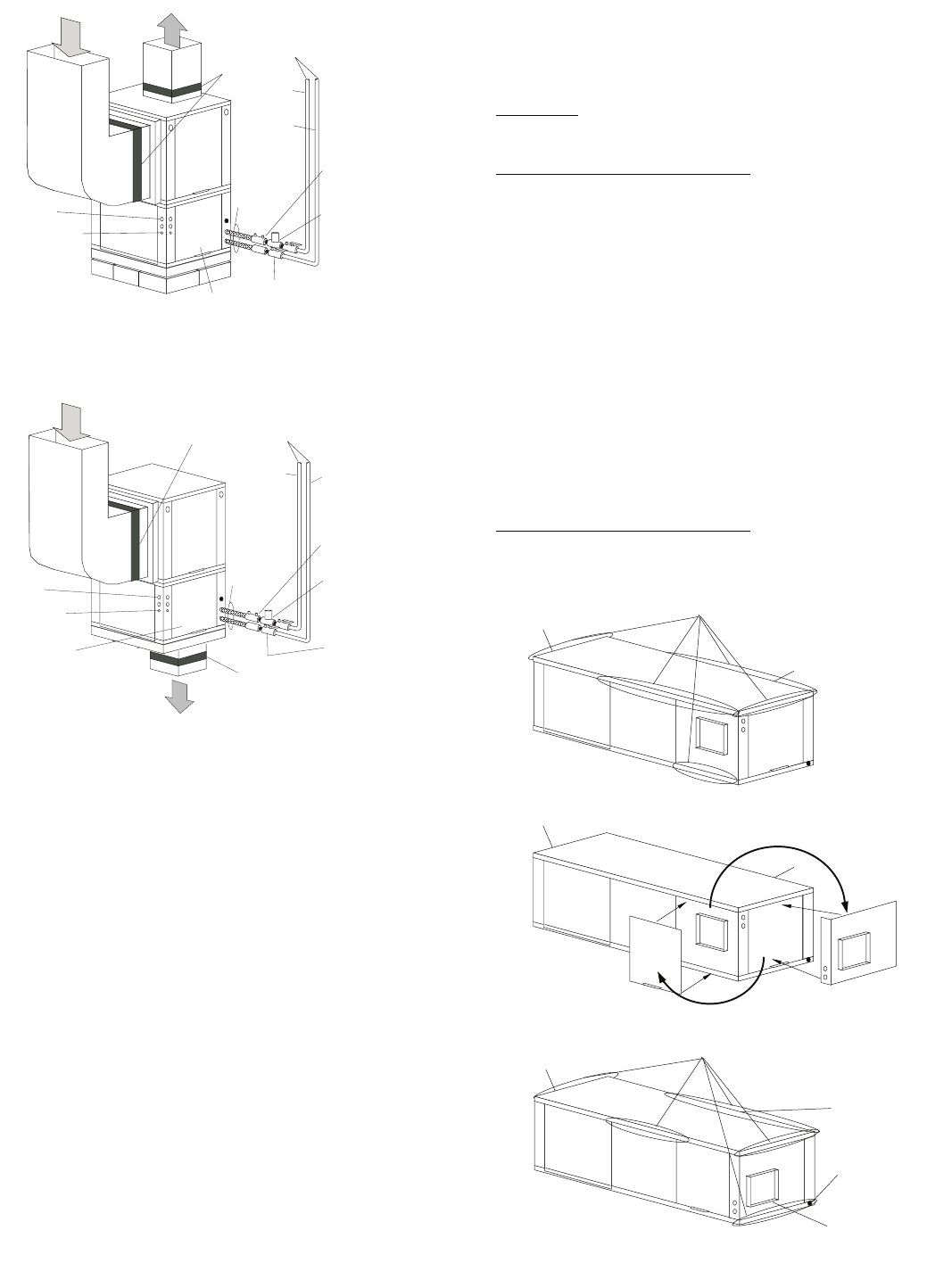

FIELD CONVERSION OF DISCHARGE AIR — The dis-

charge air of the 50RHC,RHR,RHS horizontal units can be

converted between side and back discharge in the field. The

conversion process is the same for right and left return configu-

rations. See Fig. 11 and 12.

NOTE: It is not possible to convert return air between left or

right return models in the field due to refrigerant piping

changes.

Preparation

— The unit should be on the ground in a well lit

area for conversion. Hung units should be taken down to

ground level before converting.

Side to Back Discharge Conversion

1. Remove screws to free the top and discharge panels. See

Fig. 11.

2. Remove the access panel and set aside.

3. Lift the discharge panel from side of unit and rotate it to

back using care not to damage blower wiring.

4. Check blower wire routing and connections for undo

tension or contact with sheet metal edges. Re-route if

necessary.

5. Check refrigerant tubing for contact with other compo-

nents. Adjust if necessary.

6. Reinstall top panel using screws set aside in Step 1.

NOTE: Location for some screws at bottom of discharge panel

may have to be changed.

7. Manually spin fan wheel to check for obstructions.

Adjust for any obstruction found.

8. Replace access panel.

Back to Side Discharge Conversion

— Follow instructions

above for Side to Back Discharge Conversion, noting the

panels would be reversed.

Return

Air

Power

Thermostat

Wiring

Compressor

Access Panel

Balancing Valve

(field installed

and calibrated

accessory)

Field-supplied

stainless steel

braid hose

with integral

“J” swivel

Low Pressure

Drop Water

Control Valve

(optional)

(field-installed

accessory)

Ball Valve with optional

integral P/T plug

(typical for supply and

return piping)

Water

Out

Water

In

Building

Loop

Supply Air

Flexible

Connection

NOTE: Ball valve with integral pressure temperature plug recommended.

Fig. 9 — Typical Vertical Installation —

50RVC,RVR,RVS Units

Return

Air

Power

Thermostat

Wiring

Compressor

Access Panel

Balancing Valve

(field-installed

and calibrated

accessory)

Field-supplied

stainless steel

braid hose

with integral

“J” swivel

Low Pressure

Drop Water

Control Valve (optional)

(field-installed

accessory)

Ball Valve with optional

integral P/T plug

(typical for supply and

return piping)

Water

Out

Water

In

Building

Loop

Supply Air

Flexible

Connection

Flexible

Connection

NOTE: Ball valve with integral pressure temperature plug recommended.

Fig. 10 — Typical Downflow Installation —

50RDS Units

Return Air

Remove Screws

Return Air

Rotate

Move to Side

Side Discharge

Return Air

Discharge Air

Drain

Back Discharge

Replace Screws

Water

Connection End

Water

Connection End

Water

Connection End

Fig. 11 — Conversion Left Return,

Side Discharge to Back Discharge